Locknut

A technology of anti-loosening nuts and nut bodies, which is applied in the field of fastener manufacturing, can solve problems such as complex processing, easy loosening, and increased number of parts, and achieves the effects of wide application environments, good anti-loosening effects, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

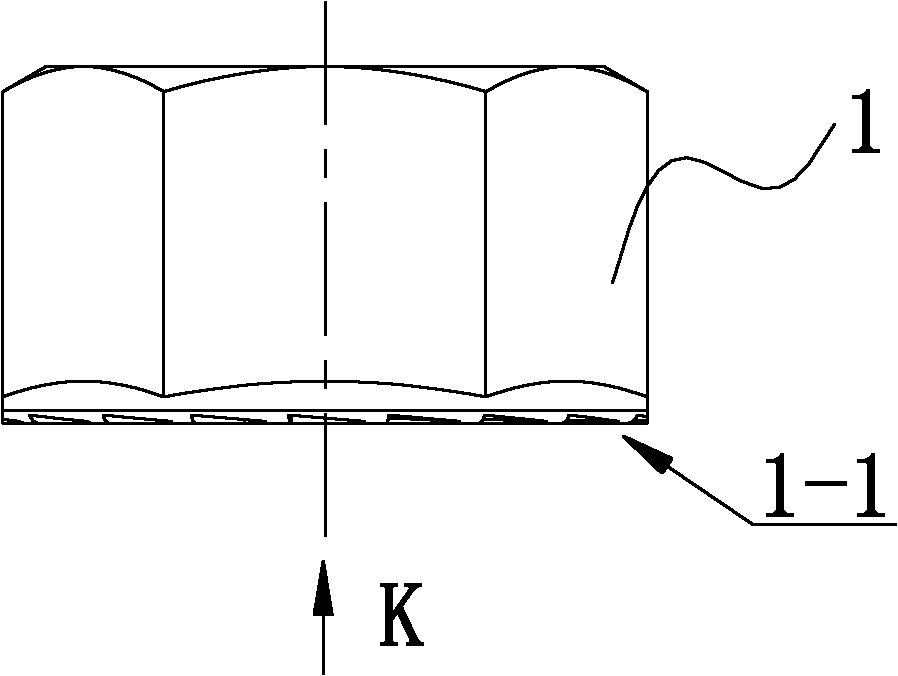

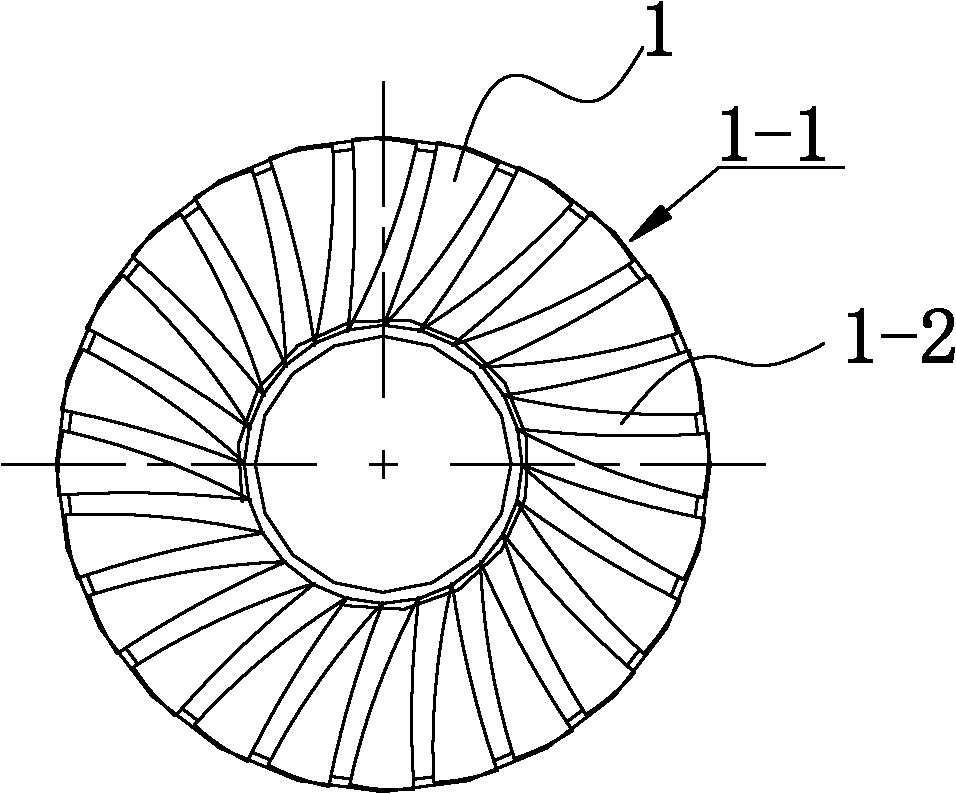

[0024] see figure 1 with figure 2 , a locknut, comprising a nut body 1, the nut body adopts a hexagonal nut, the end surface of the hexagonal nut is provided with a frictional surface 1-1 that increases the frictional force between the contact surface, and the frictional surface is preferably a ratchet Teeth 1-2 structure, the ratchets are helical teeth, and the ratchets are evenly distributed on the circumference.

Embodiment 2

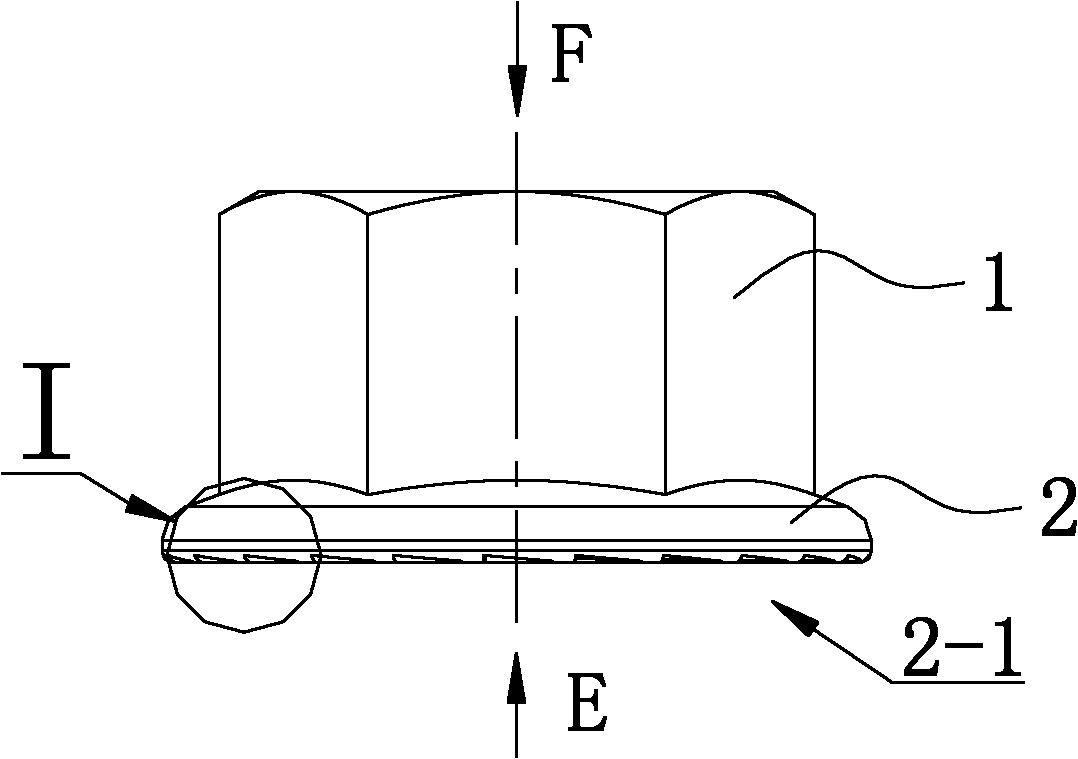

[0026] see Figure 3 to Figure 7 A kind of anti-loosening nut, comprises nut body 1, and nut body adopts hexagonal nut, and one end of described hexagonal nut is provided with flange surface 2 integrated with hexagonal nut, is provided with friction surface 2-1 on flange surface 2 , the friction surface is preferably a ratchet 2-2 structure, the ratchets are helical teeth, and the ratchets are evenly distributed on the circumference.

[0027] see Figure 8 ,Using state: That is to say, ordinary hexagonal nuts are used, and a friction surface is added on the end surface of the hexagonal nut, so that there is a large friction force between the nut and the contact surface after installation and use, so that the connecting body is in a long-term vibration environment. Not easy to loose, to achieve the purpose of anti-loosening. In the disassembly type, as long as a wrench is used to overcome the bite force, it can be disassembled smoothly.

[0028] Therefore, the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com