Automatic kelp seedling gripper

A technology of seedling clamping machine and kelp, which is applied in seaweed cultivation, horticulture, botany equipment and methods, etc., and can solve the problems that the rope cannot be automatically fed and the efficiency cannot be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

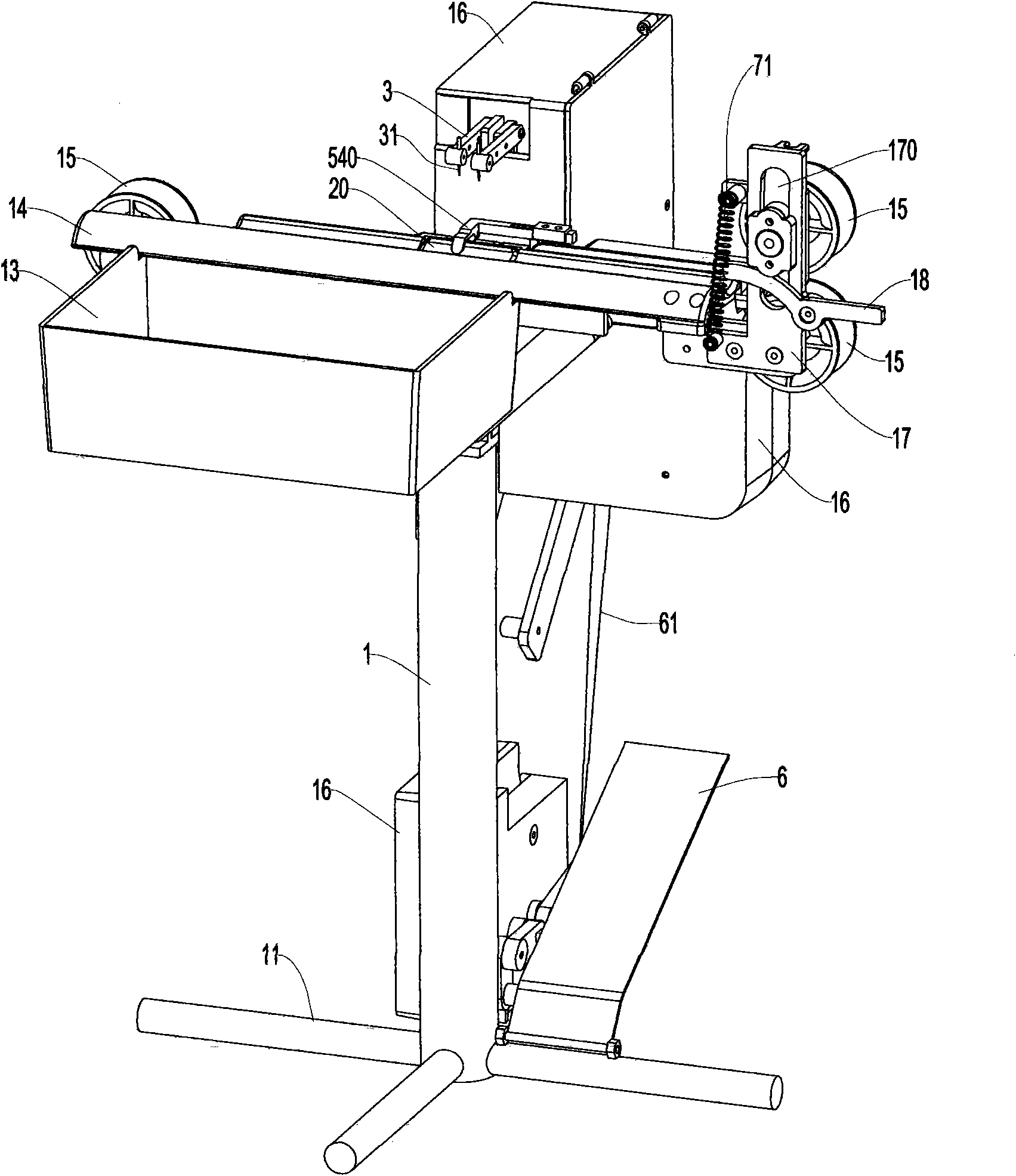

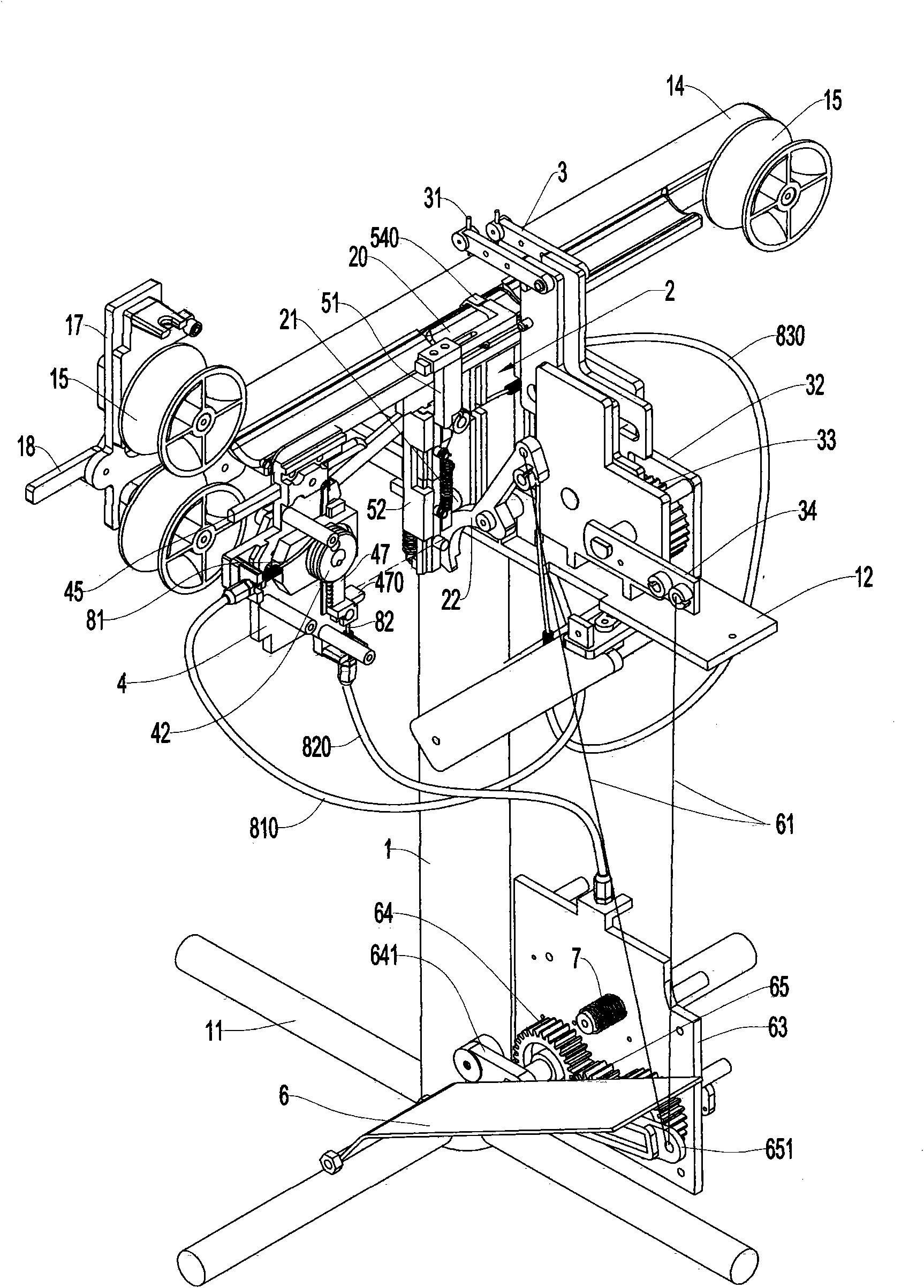

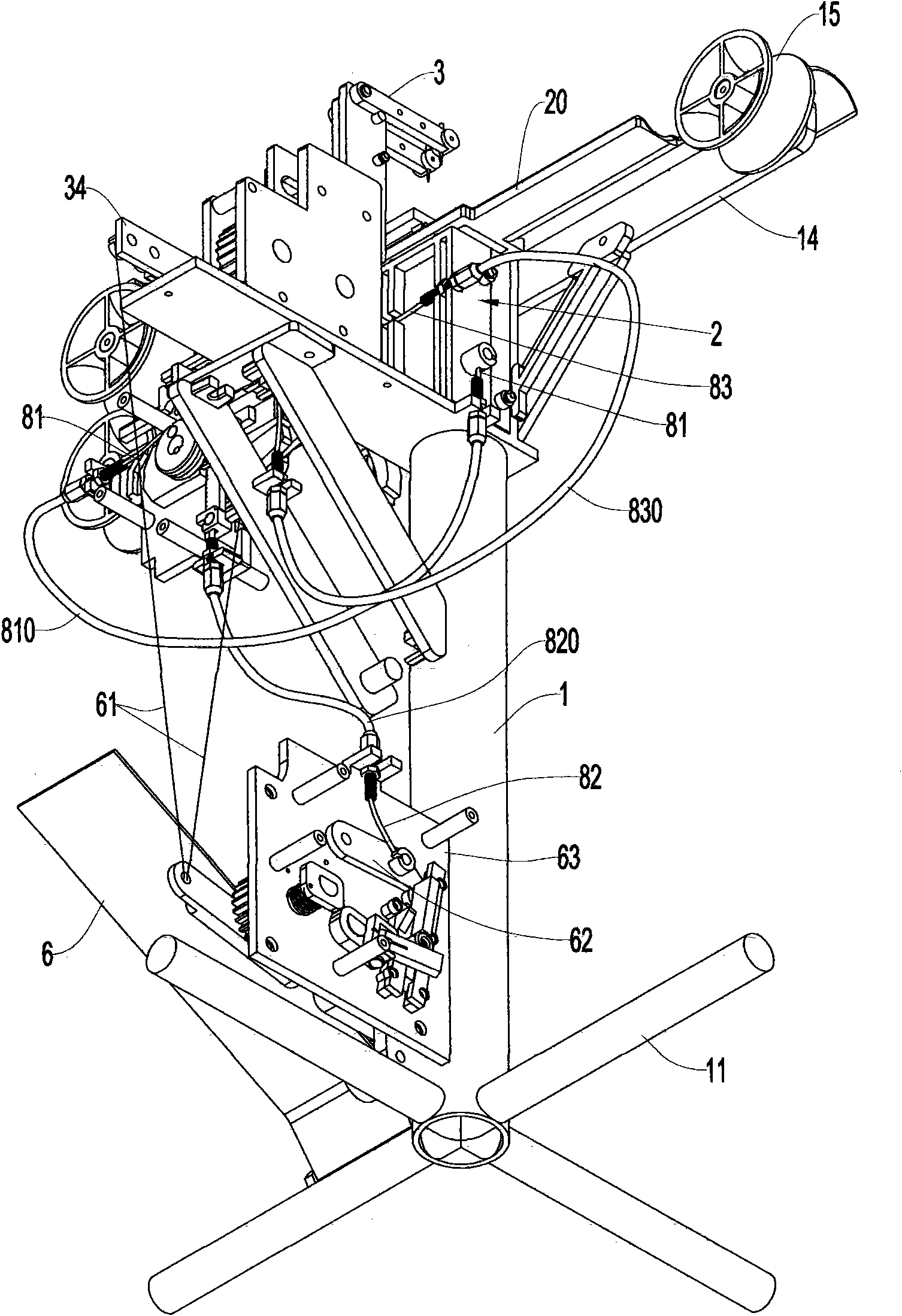

[0050] refer to figure 1 , figure 2 with image 3 , a fully human-driven portable automatic kelp clamping machine, the main body of the bracket 1 is a pipe fitting, the ground end is welded with an inherent bracket foot pad 11, the upper end is welded with a bracket supporting plate 12 for fixing the rope dividing mechanism, and the lifting rope groove 2 Pivoted in the vertical rail on the bracket pallet, forming a lifting action; the side of the lifting rope groove 2 is provided with a driving convex point 21, and the driving convex point 21 can be fixed by a cam arm 22 on the bracket pallet 12 Touch, the cam arm 22 is connected with the pedal mechanism through the steel wire 61; in order to reduce the burden of the lifting rope groove 2, a rope frame 14 is fixed on one side of the bracket supporting plate 12, and the two ends of the rope frame 14 are respectively provided with pulleys 15, wherein One end of the rope is a double pulley structure, which plays the role of cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com