Stone mining process

A technology of stone and craftsmanship, applied in open-pit mine mining, earthwork drilling, special mining, etc., can solve problems such as uncontrolled, cracked and destructive stones, and achieve the effect of increasing profits and improving yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

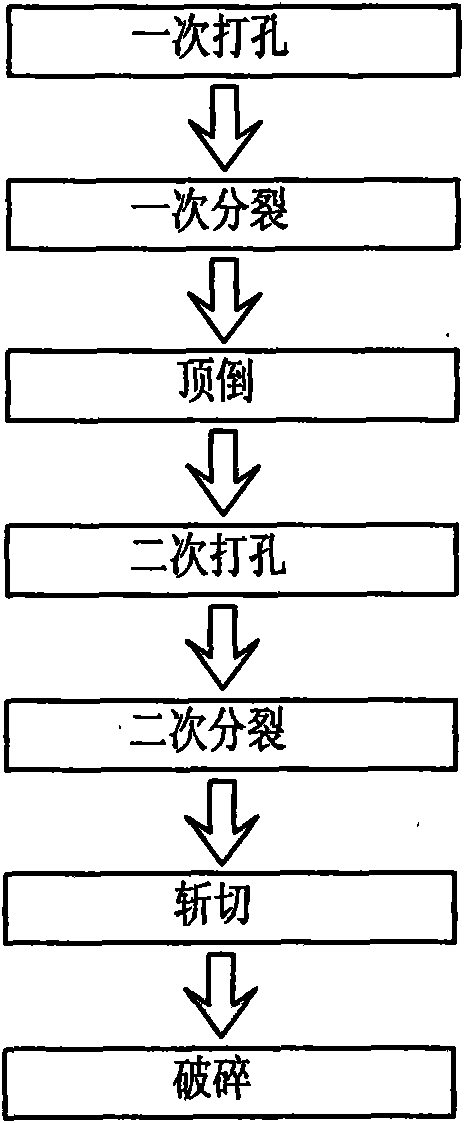

[0031] Such as figure 1 As shown, a stone mining process provided in this specific embodiment is mainly used for mining common stones such as marble and granite, and includes the following steps:

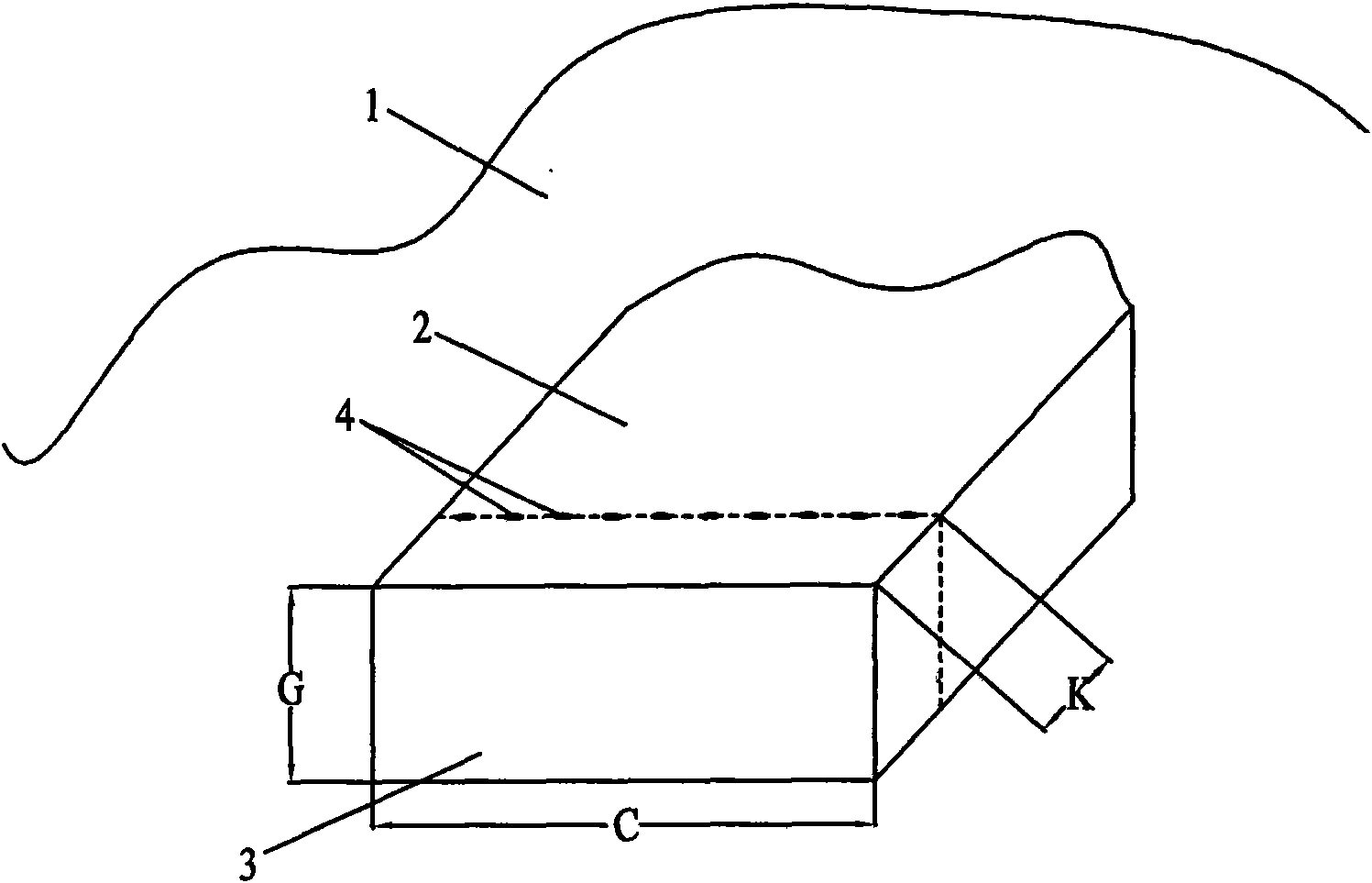

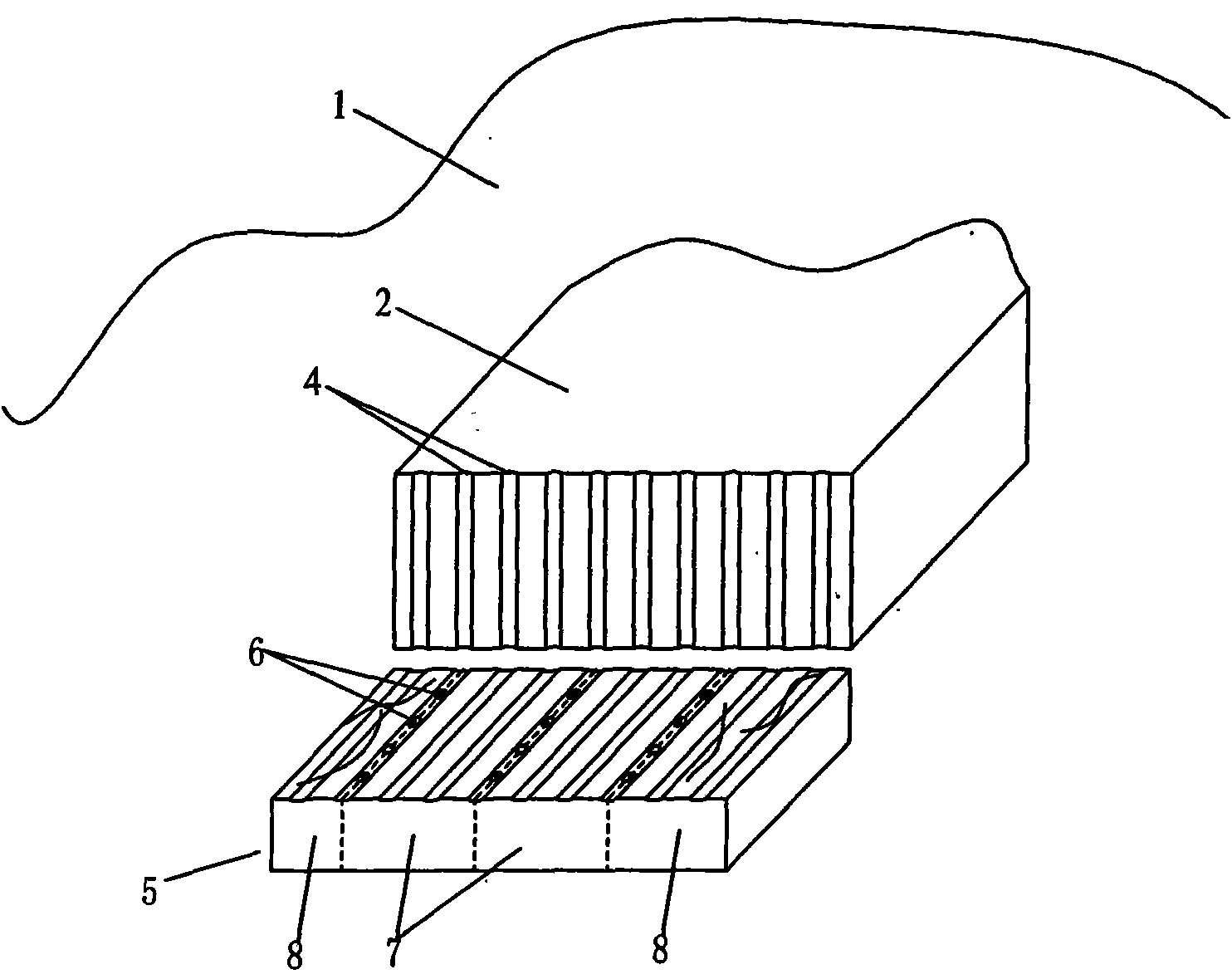

[0032] One punch: if figure 2 As shown, on the stone ore body 2 of the mine 1, a row of holes 4 are punched according to the preset position of the pre-splitting block 3, so as to prepare for the subsequent splitting. Pre-split blocks 3 such as figure 2 As shown, the length is C, the width is K, and the height is G; generally speaking, the aspect ratio G / K should be greater than 2, otherwise it is not easy to split and it is not convenient to overturn it later. The spacing between the holes 4 should generally be between 10 and 100 cm, preferably the hole spacing ranges from 10 to 50 cm.

[0033] Punching 4 can use common pneumatic pick, also can use hydraulic rock drilling machine, hydraulic rock drilling jumbo, according to pre-split position, punch a row of holes 4. Pneumati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com