Automatic detection method of static contact angle

A static contact angle, automatic detection technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of not being able to automatically obtain the anti-interference ability of the water drop edge, poor practicability, and not strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

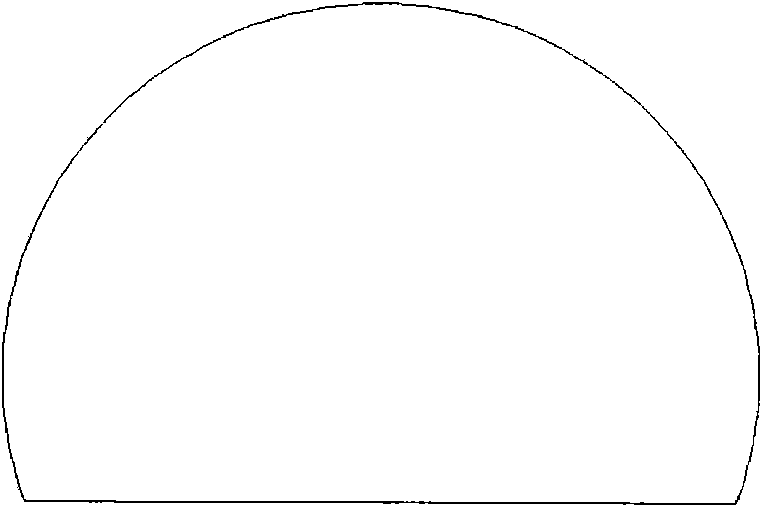

[0064] This embodiment verifies the effect of the simulated water drop image.

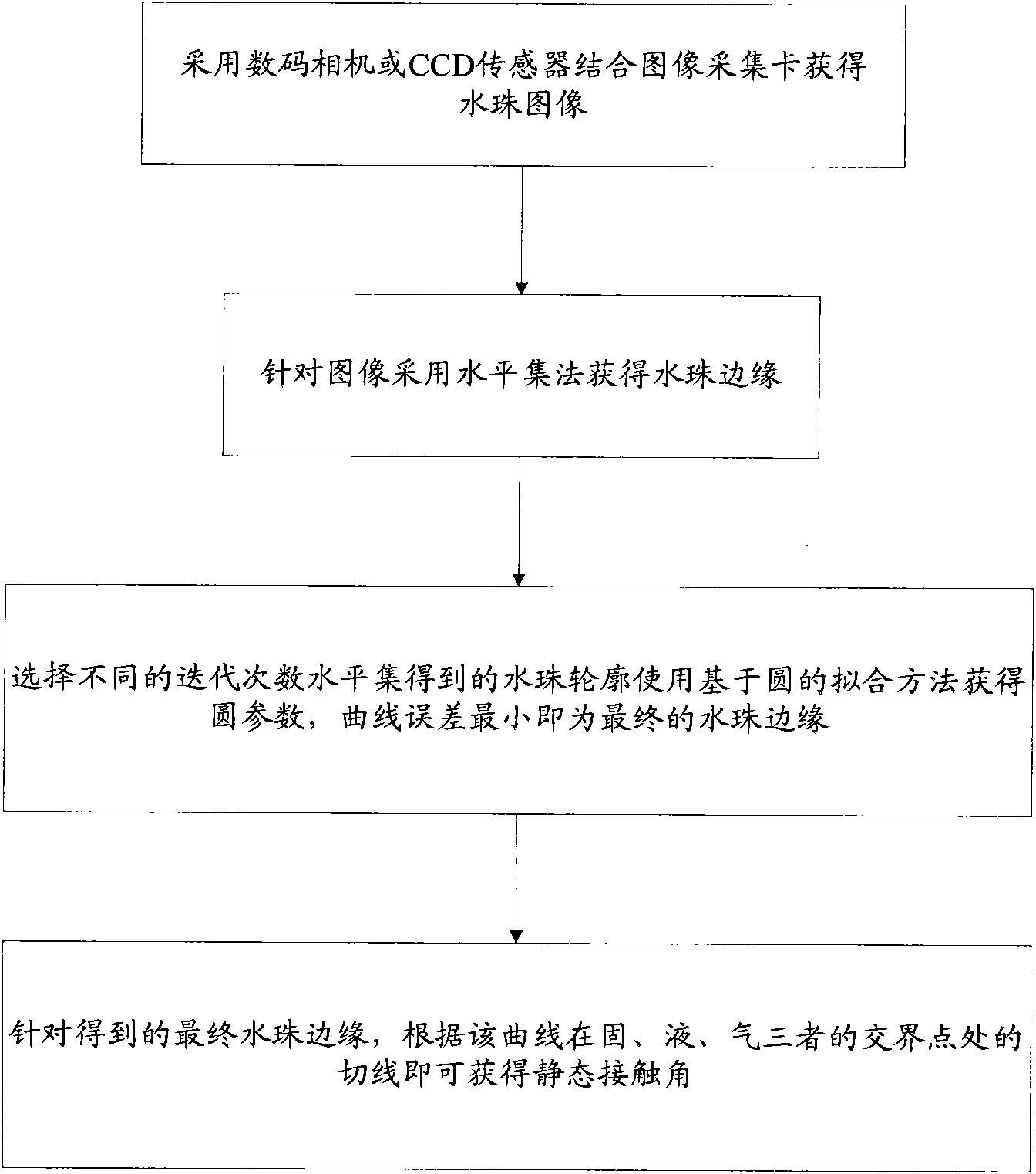

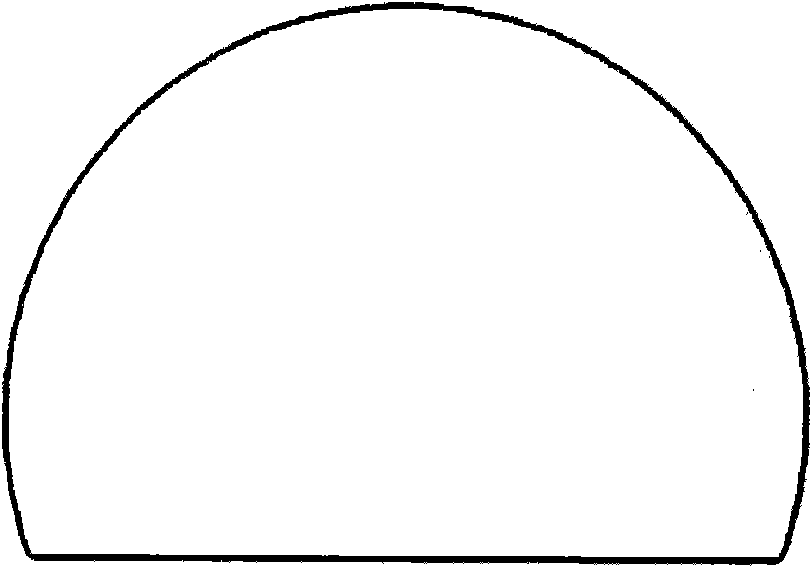

[0065] Such as Figure 2a As shown, the simulated droplet image with a contact angle of 110°, and the image obtained after 1350 iterations of fitting by the level set method, such as Figure 2b shown.

[0066] In the range of 2000 iterations, after every 50 times, the droplet edge obtained by the level set method is fitted by the above method, and the one with the smallest fitting error is selected. The corresponding static contact angle is 110.41°, which is only 110° from the theoretical value. The difference is 0.41°. The reason for the error is that the obtained edge is the peripheral curve of the droplet edge, and the error will be further reduced as the image resolution increases. The simulated droplet image belongs to the case where the edge is sufficiently clear, which also shows that the present invention can obtain the static contact angle with very high accuracy if the edge of the dropl...

Embodiment 2

[0068] The water drop image in this example is obtained on the RTV silicone rubber coating with deionized water droplets. The thickness of the coating is about 3mm, and the volume of the water drop is about 5μL. Taking pictures of the water drops, the obtained image has 3648 pixels in the horizontal direction and 2736 pixels in the vertical direction. Such as image 3 As shown, the edge of the visible water drop image is not particularly clear, especially at the junction of gas, liquid, and solid, which makes it difficult to automatically obtain accurate contact angles.

[0069] The water drop edge obtained by the level set under different calculation times is as attached Figure 4a ~d, where the edge of the water drop is represented by a black line in the figure. The level set under different iterations will get different edges. When the number of iterations is small, the curve obtained will be larger than the edge of the water drop. When the number of iterations is too lar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com