Full circular motion limiting method and equipment

A full-circle, motion technology, applied in the direction of feedback control, etc., can solve the problems of occupying space and cannot meet the requirements of full-circle motion, and achieve reliable performance, low cost, and simple processing logic.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

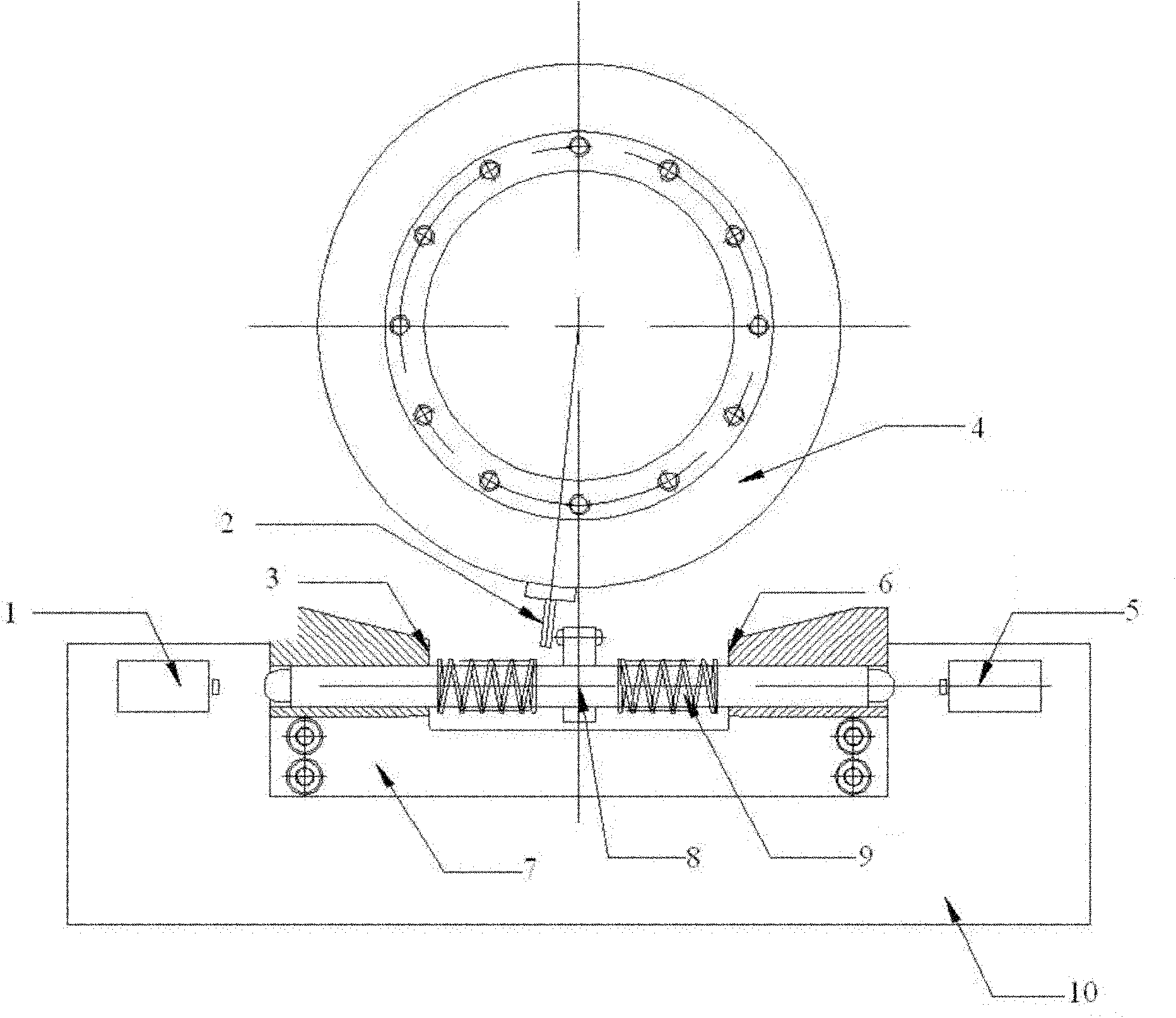

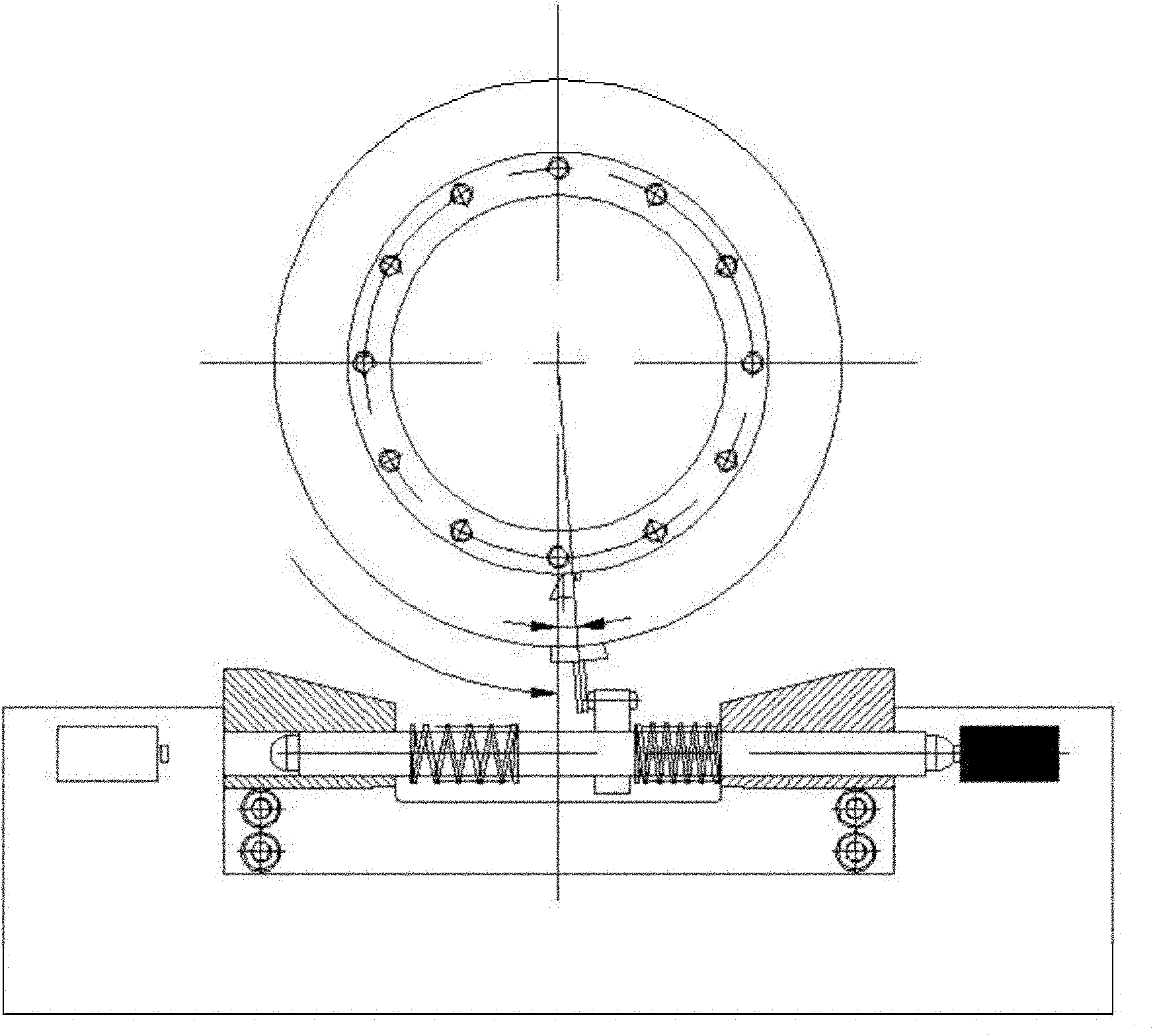

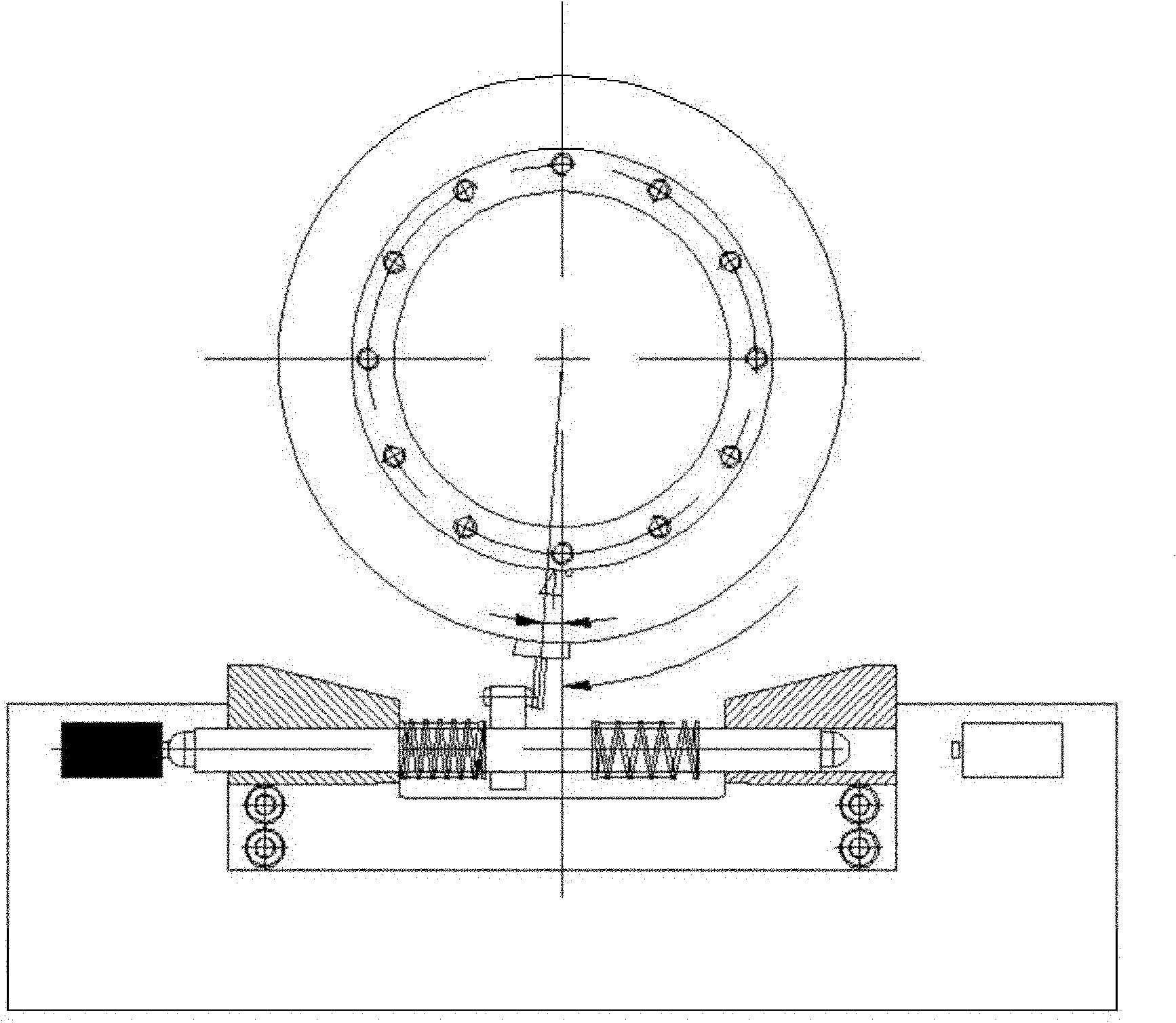

[0019] Embodiment 1: The limit of the movement of the azimuth axis of the "two-dimensional antenna test turntable", the rotation range is 360 degrees, so as to ensure that the antenna signal pattern of the full circumference is given. At an appropriate position outside the rotating part of the azimuth axis, a "rotation feeler rod" is installed, which rotates with the rotation of the azimuth axis; see figure 1 :

[0020] On the fixed part (fixed base plate 10, fixed seat 7) of azimuth shaft (rotating shaft) 4, a set of position limiting device is installed, and profile is a cuboid, and its two ends are touch switch 1,5 (as travel switch, contact switch, Photoelectric switch, etc.), used to generate limit signals, the center along the long axis is a slidable "sliding rod" 8, a "stopper" protrudes from the center of the "sliding rod" 8, and the two sides of the "sliding rod" Each cover a compression spring 9.

[0021]

[0022] The processing flow is as follows:

[0023] ⑴.. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com