Cyclone pulverized coal burner

A technology for pulverized coal concentration and stable combustion, applied in burners, burners for burning powder fuel, combustion methods, etc., can solve problems such as large wear of pulverized coal channels and reduction of nitrogen oxide emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The following examples further illustrate the technical solutions of the present invention.

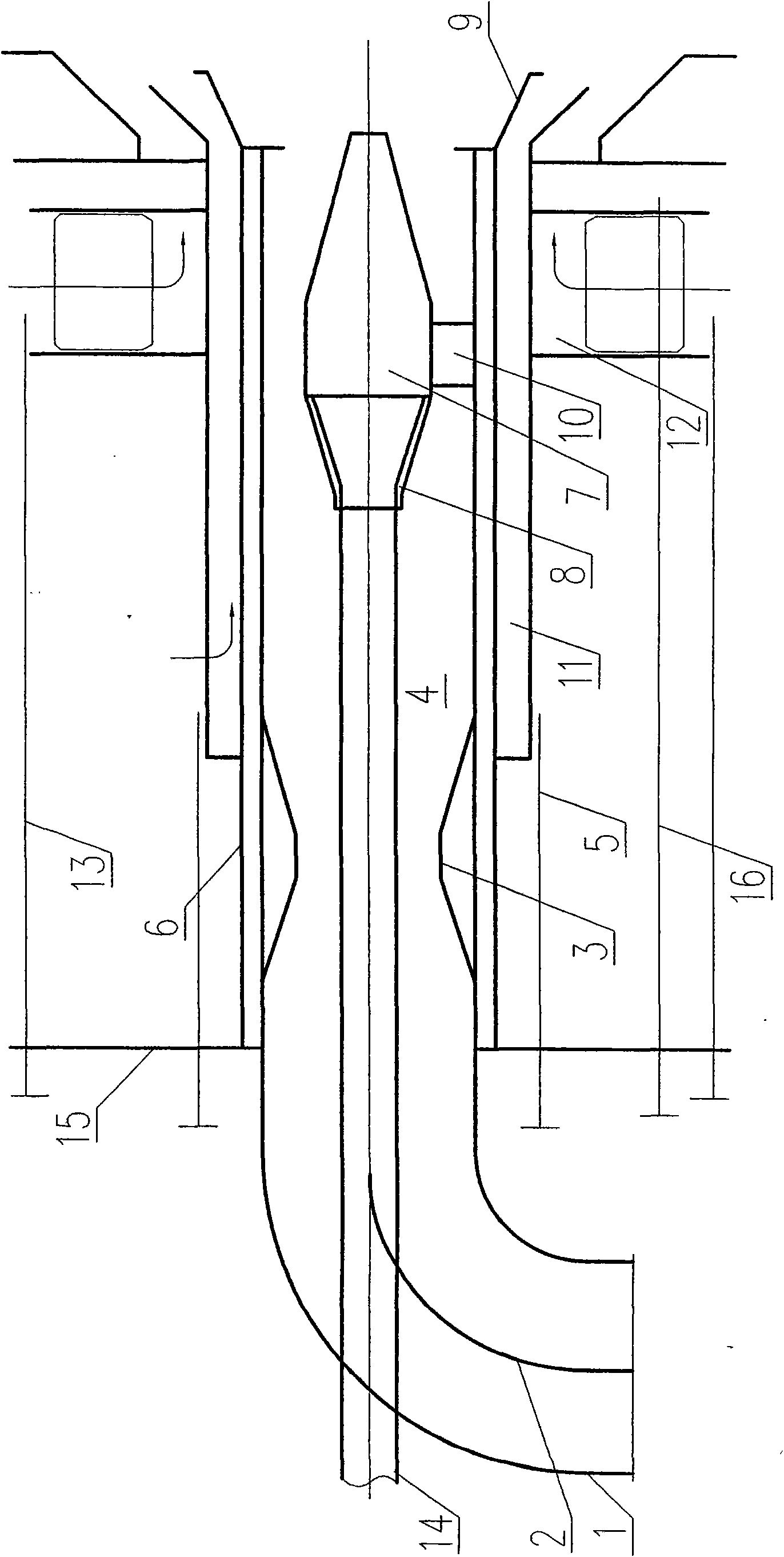

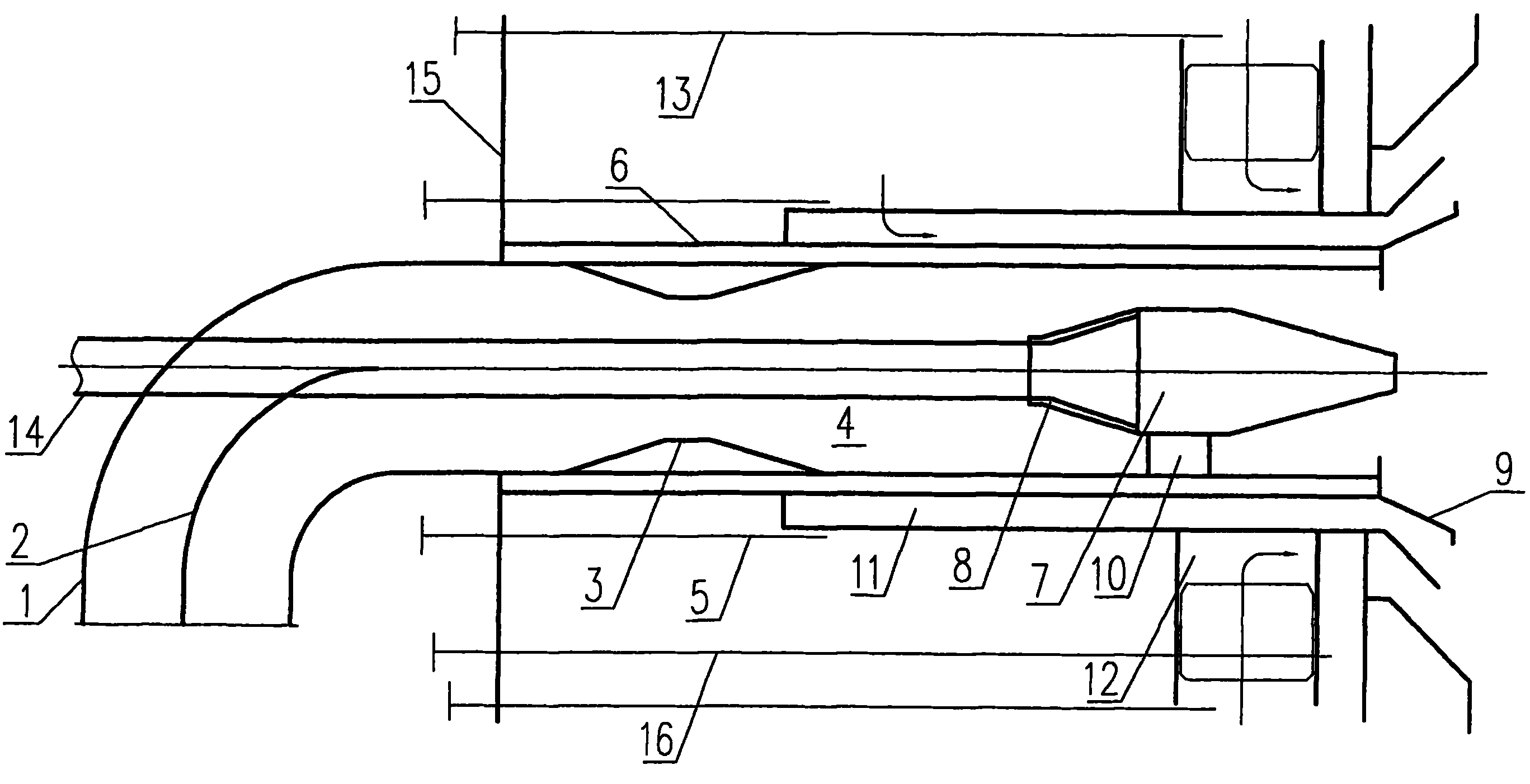

[0009] In the figure, a swirling pulverized coal burner of the present invention is composed of a primary air elbow, a flow plate, a pulverized coal concentration ring, a primary air duct, an adjusting rod, an outer sleeve, a pulverized coal concentration device, and a ceramic sleeve. , The stabilizer ring, the support plate, the primary air elbow 1, the pulverized coal flow plate 2 at the inlet of the primary air elbow, the pulverized coal concentration ring 3 at the horizontal section of the inlet of the primary air elbow, located on the furnace side of the oil gun casing 14 The pulverized coal concentrator 7 also includes the overall ceramic sleeve 8 on the windward side of the thickening device 7 and its support 10, the DC secondary air duct 11 and its air adjustment rod 5, the swirling secondary air duct 12 and its air adjustment rod 13 And 16. Since the flow-sharing plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com