Non-convex section hole-containing phononic functional material structure and manufacturing method thereof

A technology of functional materials and production methods, applied in the fields of mechanics and materials science, machinery, and acoustics, can solve the problems of incapable acoustic characteristics, and achieve the effect of simple processing and wide acoustic band gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for manufacturing a novel phonon functional material structure containing non-convex cross-sectional holes is characterized in that it further includes the following steps:

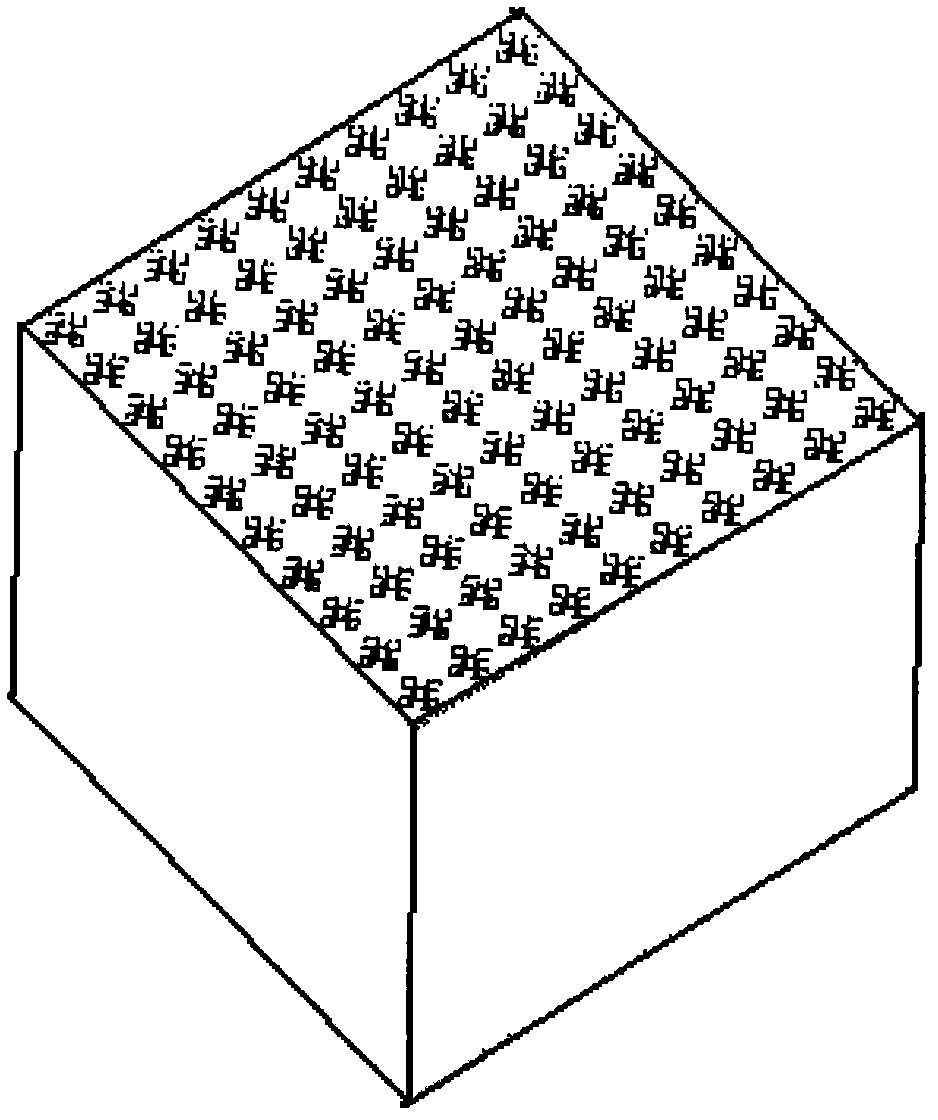

[0033] Step 1; Determination of the lattice constant: In the band structure diagram of the phonon functional material, the abscissa is the wave vector, and the ordinate is the frequency; usually the frequency corresponding to the wave whose wavelength is equal to the lattice constant in the matrix is used (c t / a,c t is the shear wave velocity in the matrix, a is image 3 The lattice constants of the square-arranged phonon-functional materials are shown, namely Figure 4 The side length of the original cell of the phonon functional material shown) is used as a reference to simplify the specific value of the eigenfrequency (Hz) to obtain a dimensionless reduced frequency or reduced frequency (denoted as Ω), which makes the calculation results consistent with the specific The lattice con...

Embodiment 2

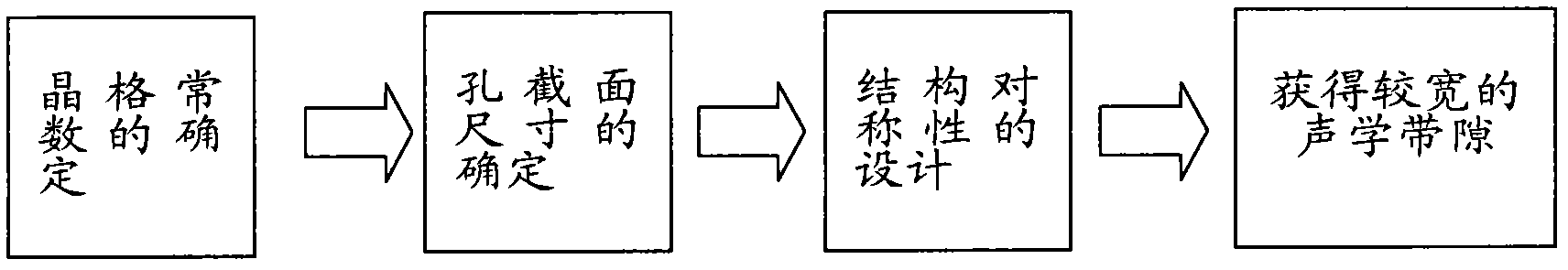

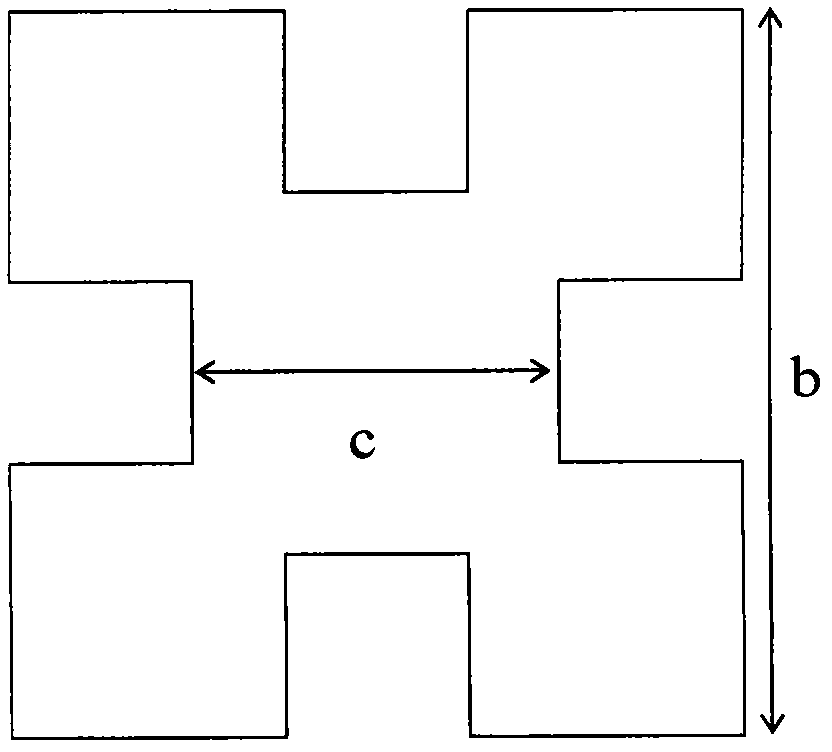

[0039] exist figure 1 In the process of determining the lattice constant of the structure, the requirements for the acoustic properties of the structure must be met; the schematic diagram of the hole section is shown in figure 2 As shown, according to the required porosity and the determined lattice constant, determine the relationship between the pore cross-sectional size, by adjusting the size of the pore cross-sectional size and the symmetry of the structure, such as image 3 The structure of the new phonon functional material with non-convex cross-section holes shown in the figure must satisfy that the holes are arranged in a close-packed form in the periodic direction of the structure, Figure 4 shown as image 3 The schematic diagram of the original cell.

[0040] exist Figure 5 , Figure 6 In the example shown, the porosity is 0.3675, the left picture shows a convex cross-section hole, and the right picture shows a non-convex cross-section hole. The abscissa in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com