Sprinkling deep frying pan

A deep fryer, shower type technology, applied in the field of deep fryer, can solve the problems of easy blackening of oil, large oil consumption, high energy consumption, etc., achieve fast preheating, low energy consumption, small waste oil discharge, and convenient cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

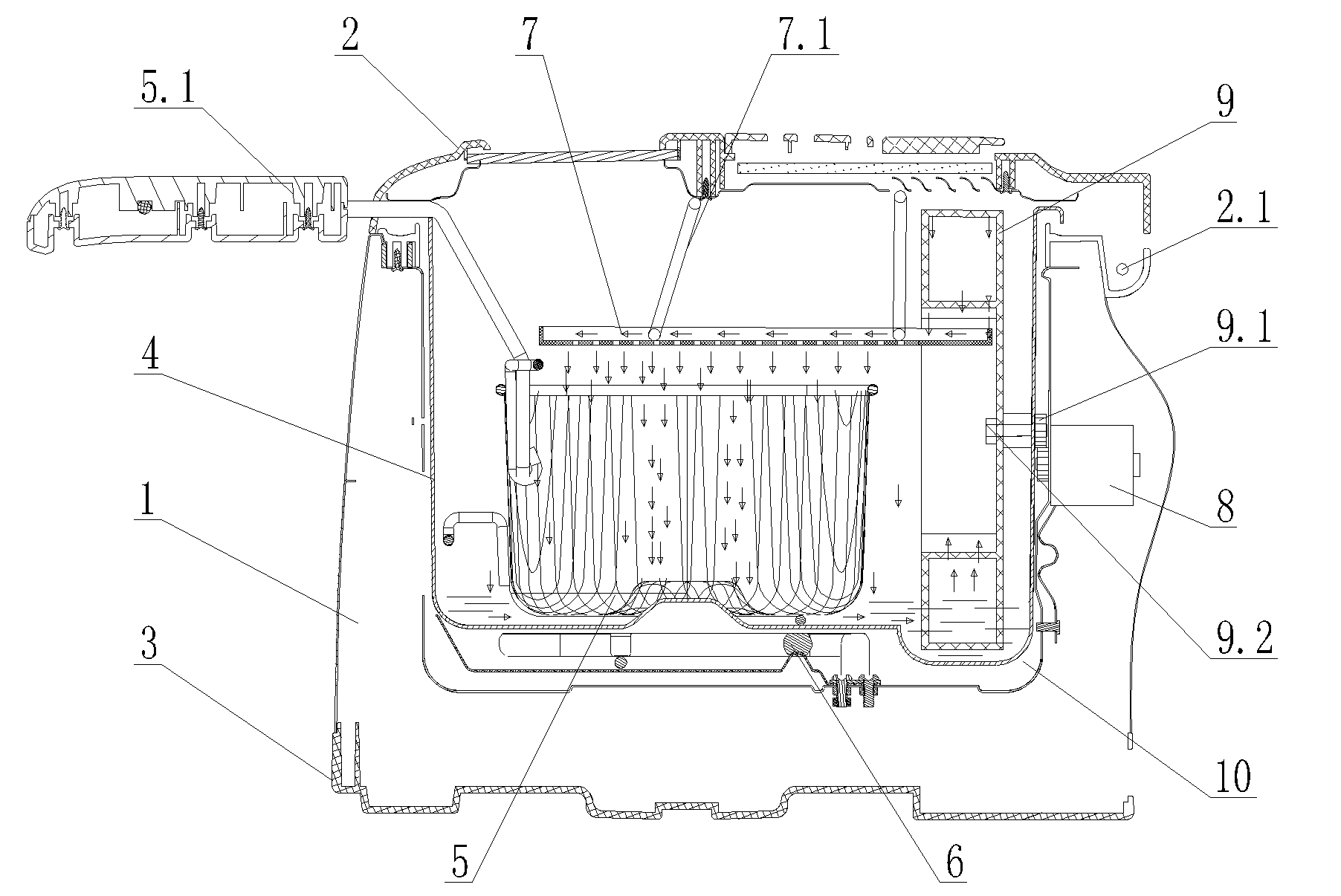

[0018] see Figure 1-Figure 3 , the sprinkler type fryer includes a body composed of an upper cover 2, an outer shell 1 and a bottom cover 3, a pot liner 4 is arranged inside the body, a heater 6 is arranged at the bottom of the pot liner, and a frying basket 5 passes through the frying pan. Basket handle 5.1 is hung on the inside of the inner pot 4, and the inner portion of the inner pot 4 is provided with an oil pumping device that can pump up the oil at the bottom of the inner pot and sprinkle it evenly in the frying basket 5.

[0019] The oil-suction sprinkler device includes an oil-sucker assembly that can pump up the oil at the bottom of the pot liner 4 , and a sprinkler assembly that can evenly sprinkle the oil drawn by the oil-sucker assembly in the frying basket 5 .

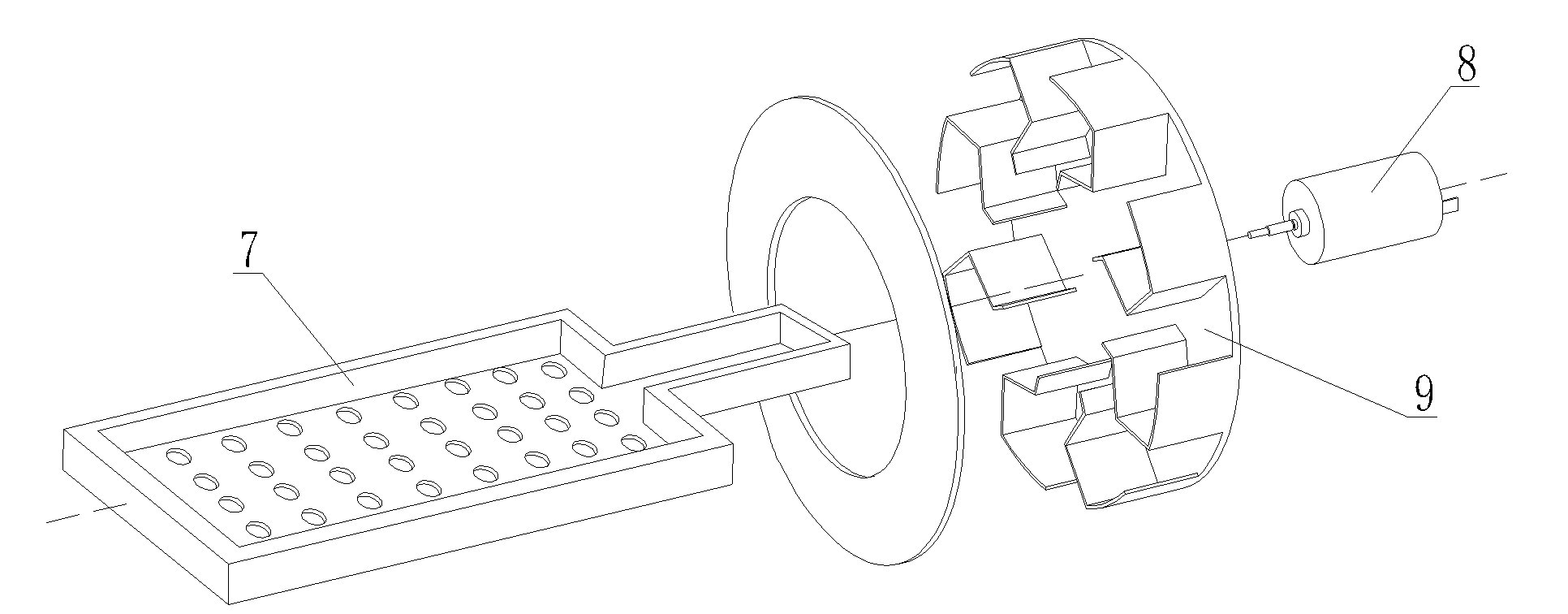

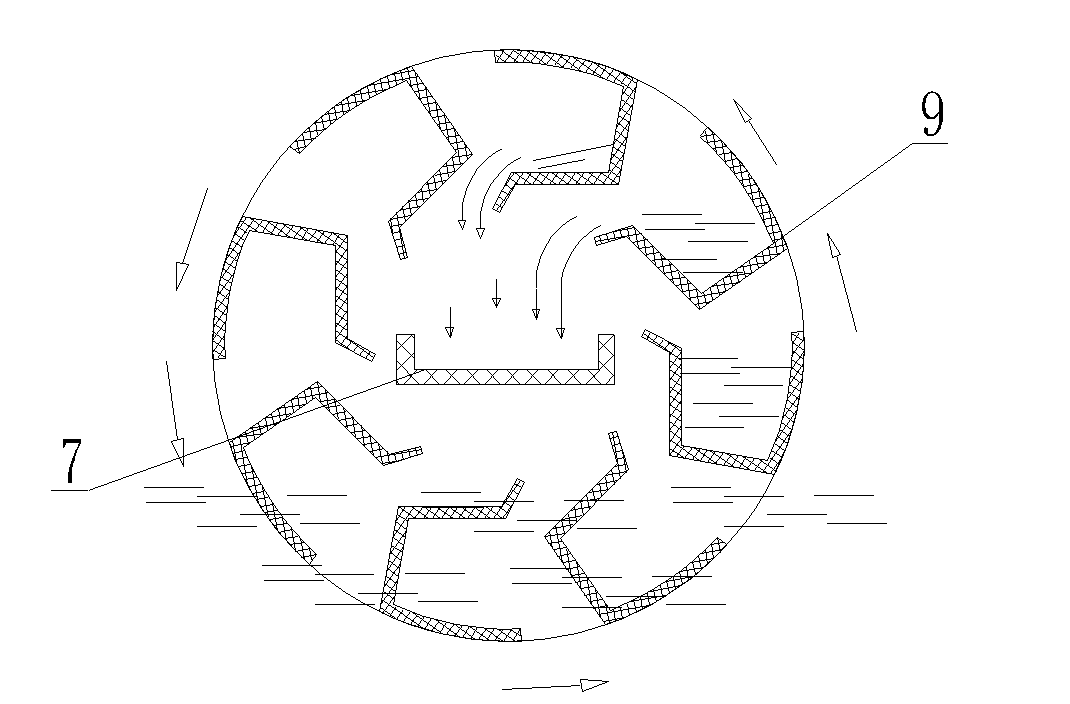

[0020] Oil pumping assembly comprises the motor 8 that is arranged on the outside of inner pot 4, and the impeller 9 that is arranged on inner pot inner 4, is provided with detachable rotating shaft 9.2 ...

no. 2 example

[0023] This sprinkle type deep fryer (not marked in the figure), its oil sucking assembly comprises the oil pump motor that is arranged on the outer side of pot liner 4, and the oil pump body that is arranged on the inside of pot liner 4; The bottom of the pot liner 4 is connected, and the oil outlet end of the oil pump body is upward and higher than the frying basket 5 and connected with the sprinkler assembly. The side part of the distributor 7 is provided with an oil receiving part communicating with the oil outlet end of the oil pump body. The oil in the pot liner 4 is pumped up from the oil inlet end of the oil pump body to the oil outlet end through the oil pump motor, and flows into the distributor 7 through the oil receiving part of the distributor 7, and is evenly distributed through the oil sprinkler holes on it. Sprinkle into the frying basket 5, fry the food in the frying basket evenly, and effectively speed up the cooking efficiency, and save fuel and energy.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com