Built-in spiral cyclone separator

A cyclone separation device and spiral technology, applied in suction filters and other directions, can solve the problems of complicated operation, harsh screeching, heavy cyclone separator, etc., and achieve the effects of reducing airflow noise, eliminating harsh screeching, and reducing pressure loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below with reference to the drawings and examples.

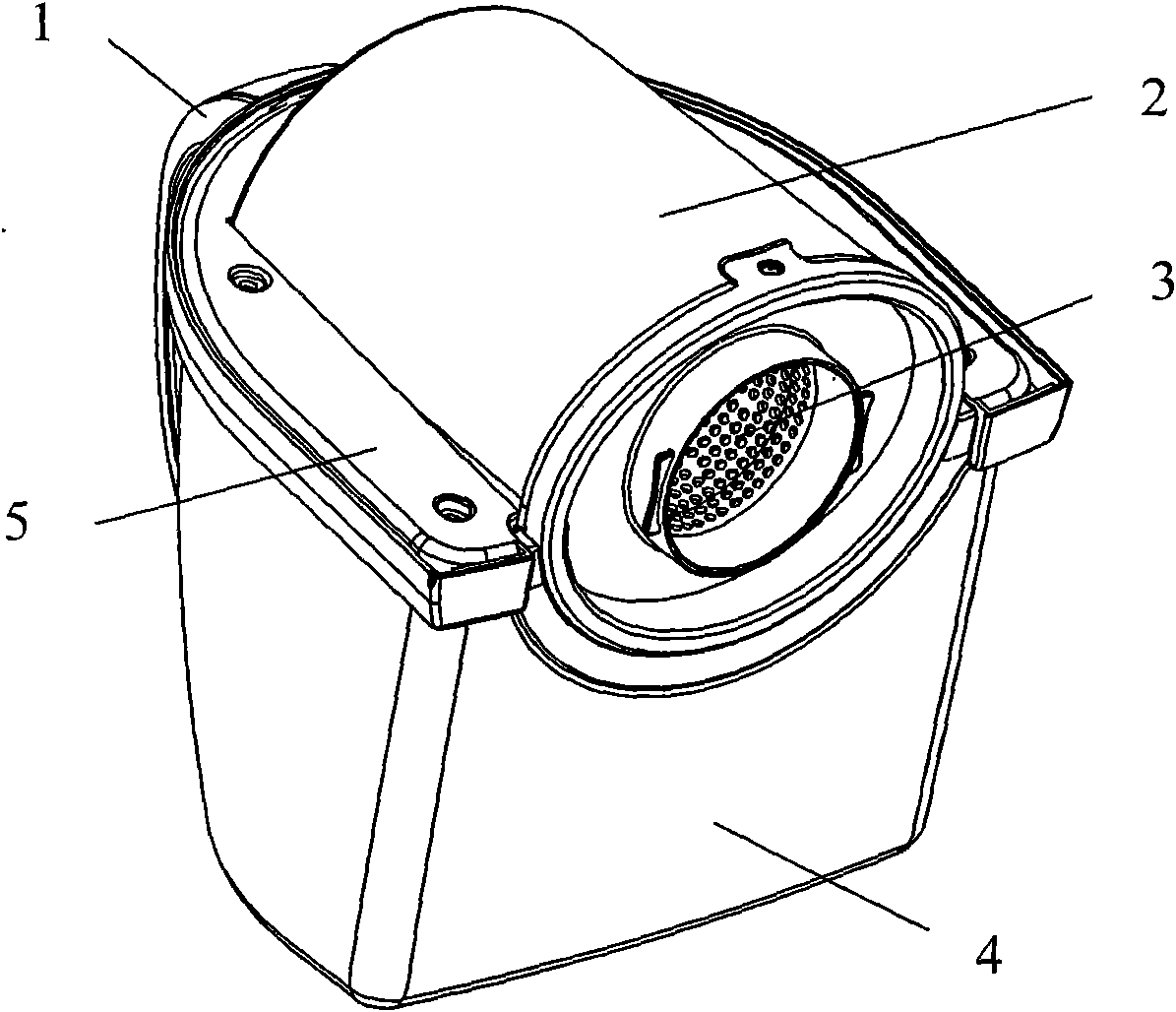

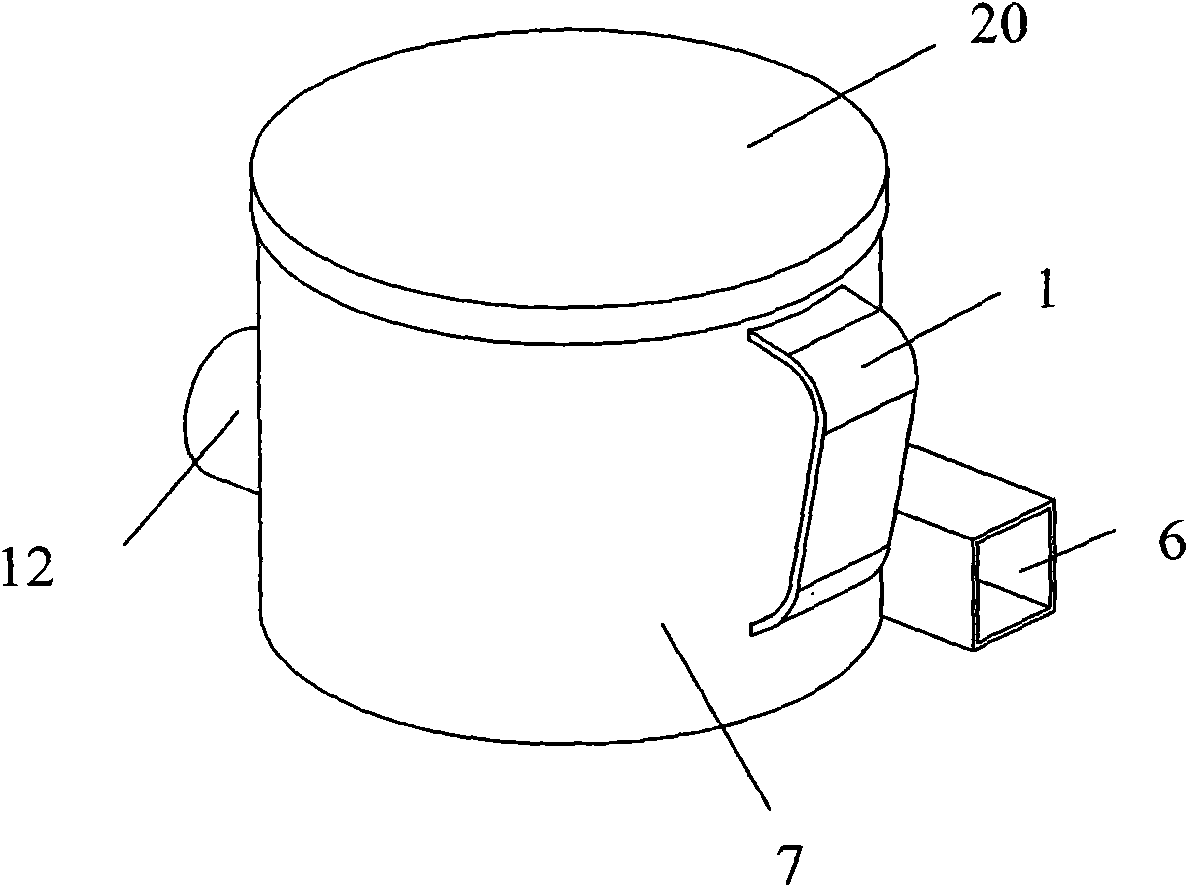

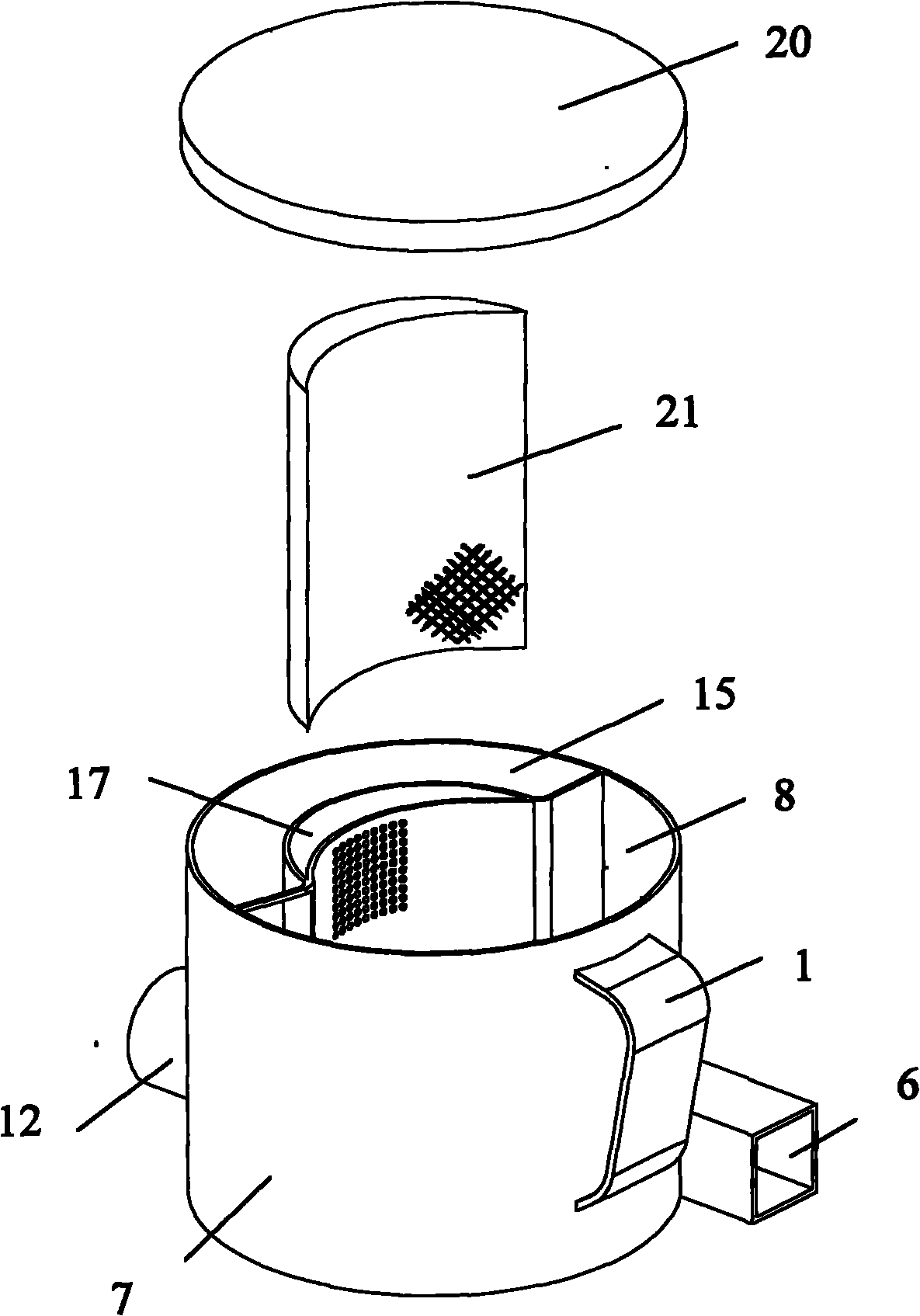

[0040] figure 2 It is a three-dimensional view of the built-in spiral cyclone separation device of the present invention; image 3 It is an exploded view of the structure of the built-in spiral cyclone separation device of the present invention; Figure 4 It is the internal structure diagram of the present invention without upper cover and filter sponge installed; Figure 5 It is a top view of the built-in spiral cyclone separation device of the present invention; Image 6 Yes Figure 5 A-A sectional view of ; Figure 7 It is a top view of another direction of the present invention; Figure 8 Yes Figure 7 The B-B section view.

[0041] The present invention has a built-in spiral cyclone separation device, such as Figure 2 to Figure 8 As shown, the built-in spiral cyclone separation device consists of a circular dust collection bucket 7 with a handle 1, an up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com