Process of carrying out reaction, rectifying and coupling to selectively hydrogenate to remove MAPD (Methylacetylene Propadiene)

A coupling and selective technology of rectification, applied in the fields of hydrocarbons, distillation purification/separation, hydrocarbon purification/separation, etc., can solve the problems such as the failure to effectively reduce the concentration of propylene and the failure to greatly improve the selectivity of propylene. , to achieve the effect of high catalyst efficiency and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

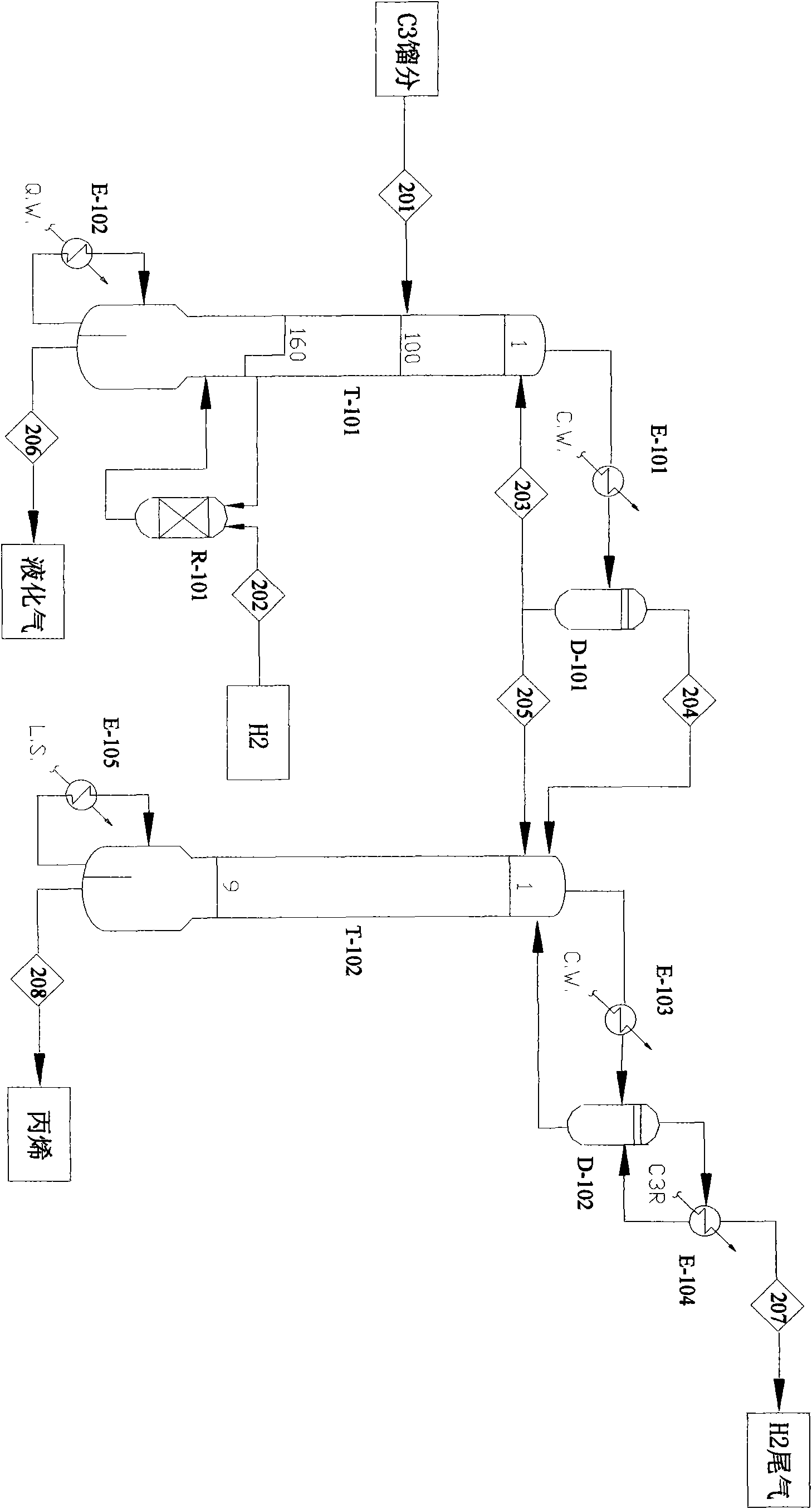

[0029] like figure 1 As shown, the C3 fraction 201 has a flow rate of 22t / h, a MAPD content of 3.5%, a propylene content of 92.8%, and enters the propylene rectifying tower T-101 from the 100th tray. The pressure inside the tower is 1.6-1.8MPa, the temperature at the top of the tower is 3°C, the reflux ratio is 13.8, and the temperature at the bottom of the tower is 5°C.

[0030] The propylene rectification tower T-101 has 160 trays in total, the 160th tray has normal gas channels, but the bottom of the downcomer is sealed to form a collection tank, the liquid is pumped out from the collection tank and put into 68kg After 202 / h of hydrogen (containing 5% methane), it enters the second fixed bed MAPD reactor R-101, which is filled with BC-L-83 catalyst 2m 3 , The reacted material enters the T-101 column tank from below the 160th plate. The second MAPD reactor is an adiabatic reactor, with one open and one standby, the inlet MAPD concentration is 0.46%, the propylene concentr...

Embodiment 2

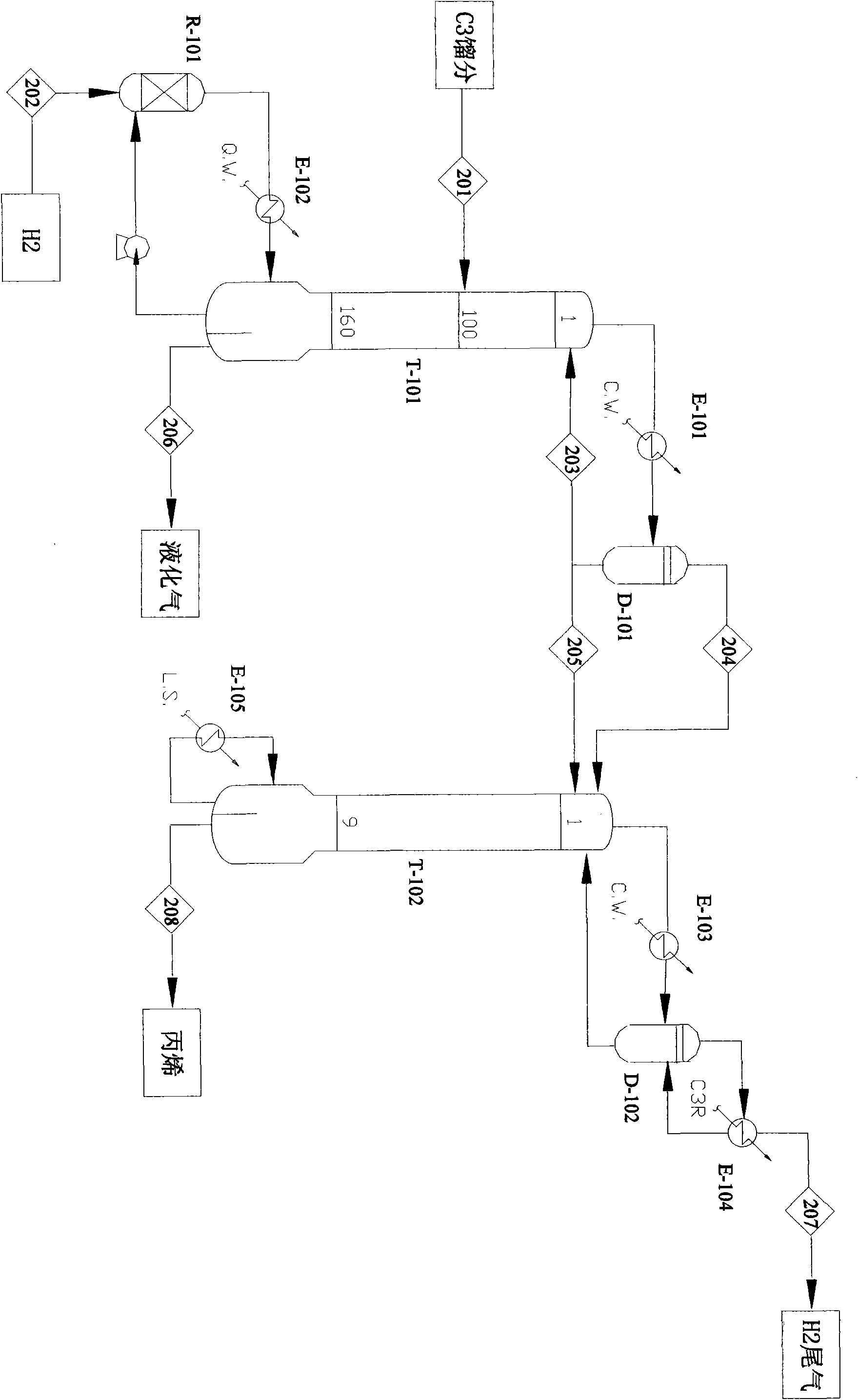

[0035] like figure 2 Shown, operating condition is the same as embodiment 1, but liquid is extracted from T-101 tower kettle with pump, enters the second MAPD reactor R-101 of fixed bed after joining the hydrogen 202 (containing 5% methane) of 68kg / h, Internal filling BC-L-83 catalyst 2m 3 , The reacted liquid is returned to the tower kettle after passing through the forced circulation reboiler E-102. The second MAPD reactor is an adiabatic reactor, with one open and one standby, the reaction pressure is 2.0MPa, the inlet MAPD concentration is 0.36%, the propylene concentration is 10.90%, the outlet MAPD concentration is 0.31%, and the propylene concentration is 10.94%. The MAPD conversion was close to 13% with a selectivity to propylene of 70%.

[0036] The production volume of the T-101 tower is 1.15t / h, and the contents of propylene and MAPD are 10.9% and 0.36% respectively.

[0037] The 204 produced in the gas phase at the top of T-101 is 1.83t / h, of which the concentr...

Embodiment 3

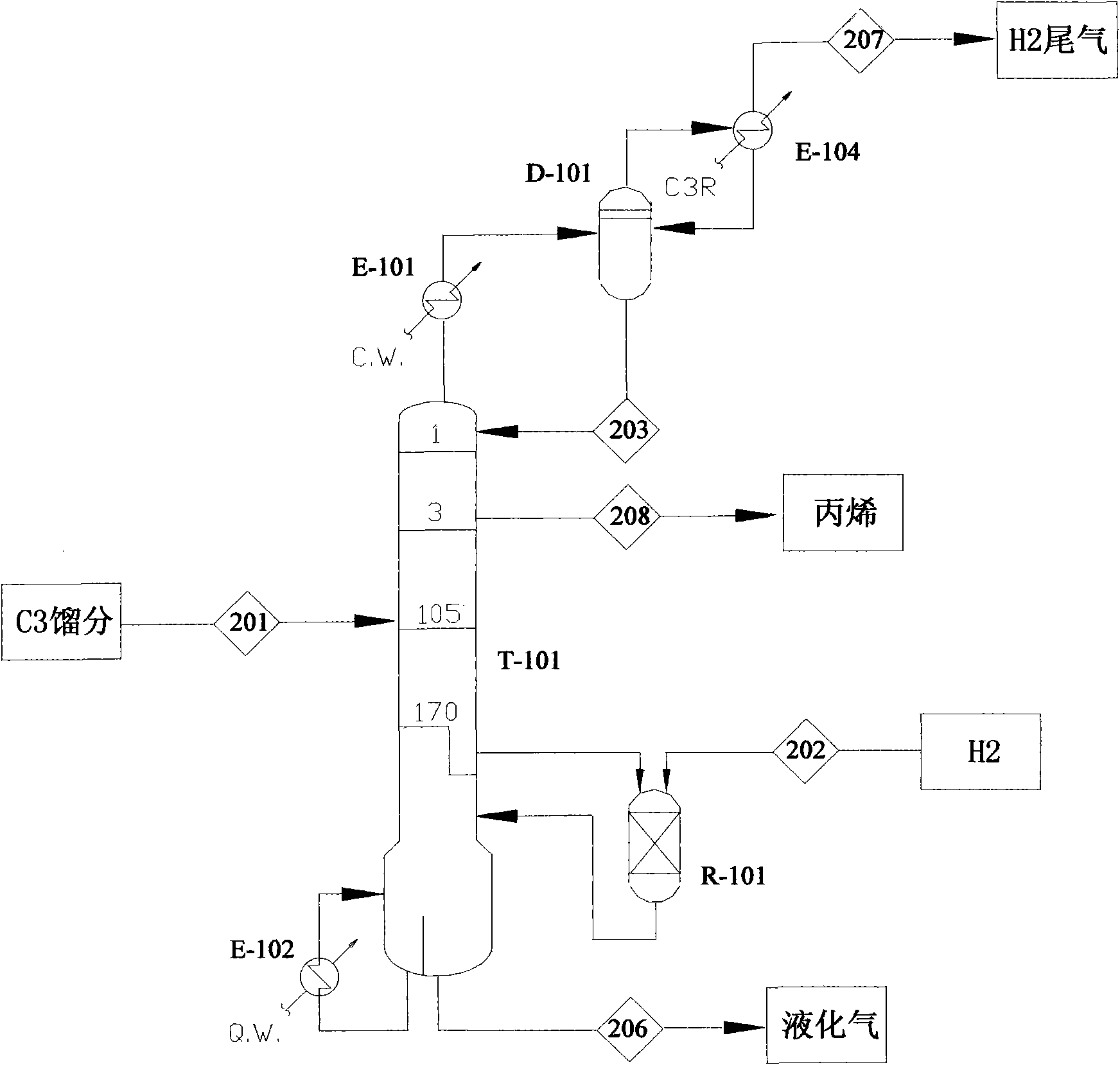

[0040] like image 3 As shown, the C3 fraction 201 has a flow rate of 22t / h, a MAPD content of 3.5%, a propylene content of 92.8%, and enters the propylene rectifying tower T-101 from the 105th tray. The pressure inside the tower is 1.6-1.8MPa, the temperature at the top of the tower is 39.4°C, and the temperature at the bottom of the tower is 5°C.

[0041] The propylene rectification tower T-101 has 170 trays in total, the 170th tray has normal gas channels, but the bottom of the downcomer is sealed to form a collecting tank, and the liquid is pumped out from the collecting tank, which is 357.7t / h, after adding 68kg / h of hydrogen 202 (containing 5% methane), it enters the second fixed bed MAPD reactor R-101, and the interior is filled with BC-L-83 catalyst 2m 3 , The reacted liquid enters the T-101 column tank from below the 170th plate. The second MAPD reactor is an adiabatic reactor, using one open and one standby, the inlet MAPD and propylene concentrations are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com