Demagnetization method for rotating along inner circle or outer circle of heavy large bearing ring

A bearing ring, a heavy-duty technology, applied in the field of demagnetization of inner or outer circle rotation, can solve the problems of being unable to stand upright and can only be placed flat, so as to save hoisting and handling, save labor and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

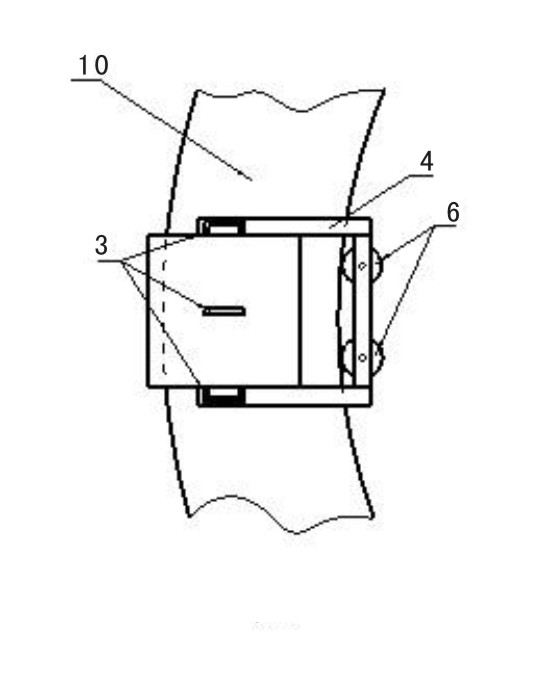

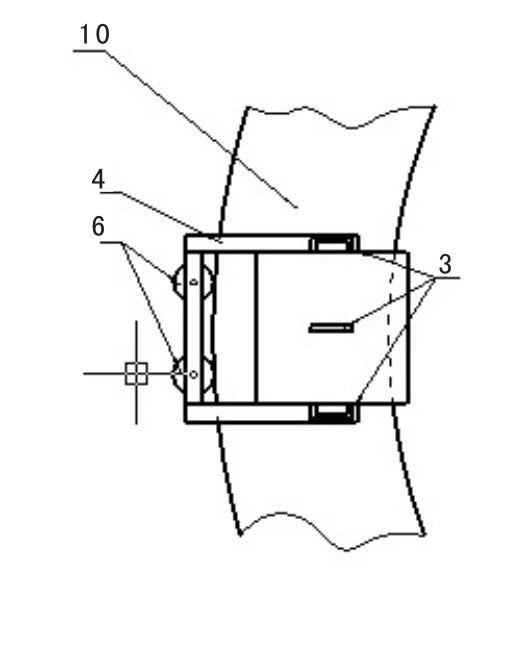

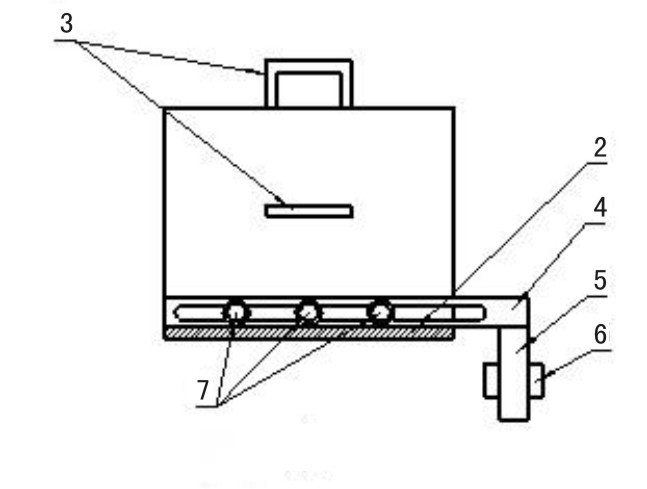

[0025] to combine Figure 4 , the demagnetization method of the present invention that rotates along the inner circle or outer circle of the heavy-sized bearing ring borrows the E-shaped iron core 8 and a group of coils 9 configured on the E-shaped iron core, the E-shaped iron core 8 and the coil 9 The working principle of the present invention is a mature known technology, but the E-type iron core 8 and the coil 9 are applied in the demagnetization method of the present invention, and its effect can make the heavy-sized bearing ring obtain demagnetization under stationary.

[0026] to combine Figure 1-2 Place the large bearing ring 10 horizontally, the axial end face of the large bearing ring 10 is in contact with the base plate 2 in the demagnetization device, and the E-type iron core 8 and the E-type iron core are reversed on the base plate 2 A set of coils 9 is configured. The lead wires of the coils 9 are arranged on the junction box outside the casing 1. The upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com