Composite impurity removing all-in-one machine

An all-in-one, cleaning technology, applied in solid separation, separation of solids from solids by air flow, magnetic separation, etc., can solve the problems of increased user cost, uncompact structure, large footprint, etc., and achieve high cost performance. , compact structure, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

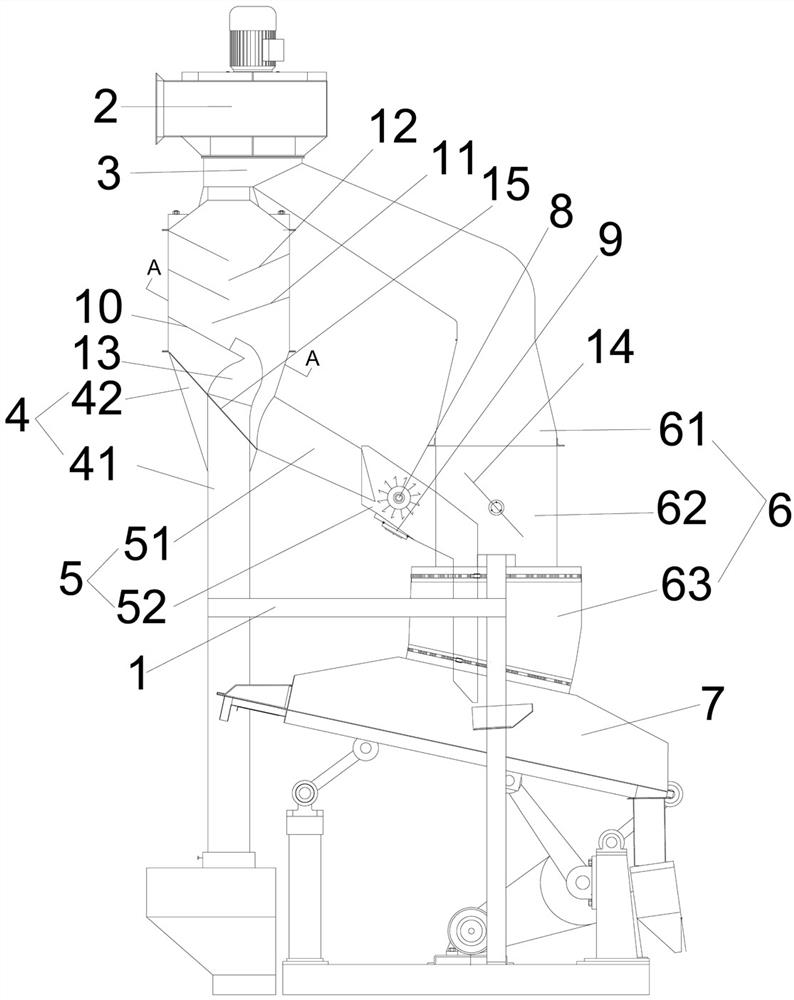

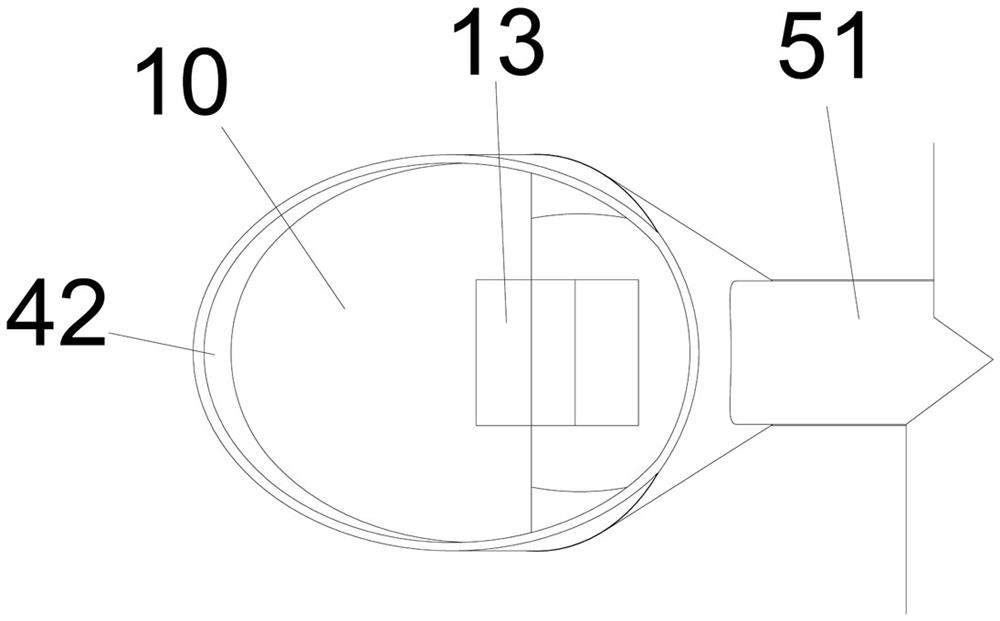

[0018] In order to make the purpose, technical scheme and advantages of the present invention more clear, reference will now be made to figure 1 , figure 2 The present invention is described in further detail with embodiment, so that the public better grasps the implementation method of the present invention, the specific embodiment of the present invention is:

[0019] A composite all-in-one machine for cleaning impurities, comprising a frame 1, on which is provided an electric blower 2, a three-way pipe 3, a wind lifter 4, a conveying pipe 5, a specific gravity hose 6 and a specific gravity destoner 7, and the electric blower The air inlet of 2 is connected with the tee pipe 3, the upper end of the wind hoist 4 is connected with the tee pipe 3, the tee pipe 3 is connected with the specific gravity destoner 7 through the specific gravity hose 6, and the wind hoist 4 is connected with the specific gravity through the conveying pipe 5. The stone remover 7 is connected, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com