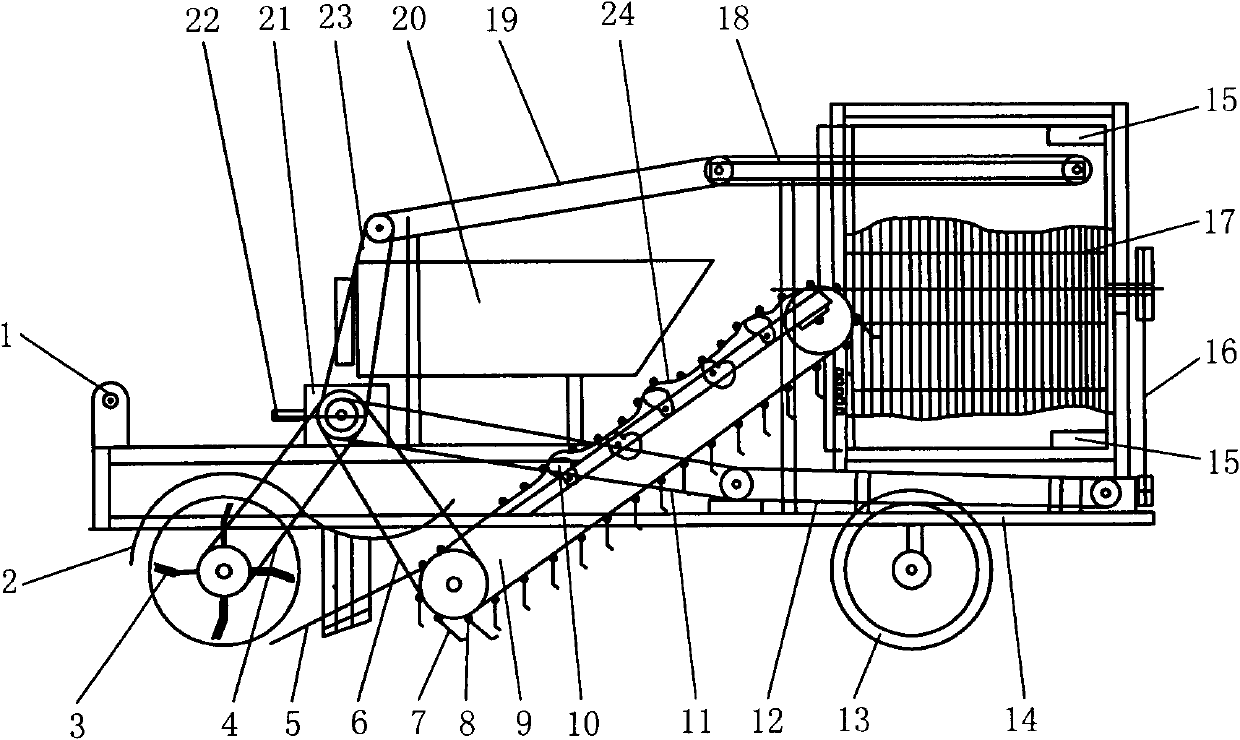

Sieve plate type cyperus esculentus harvester

A sieve-type, oil-sanded bean technology, which is applied to digging harvesters, harvesters, excavators, etc., can solve problems such as low efficiency and slow walking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

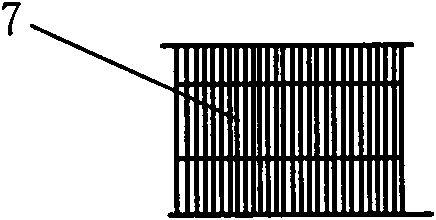

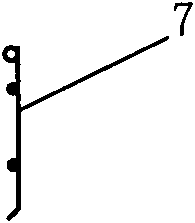

[0009] The sieve-type oil sand bean harvester is composed of a rotary harrow 3, a shovel plate 5, a sieve-type sieve conveyor belt 9, a sieve cage 17, a conveyor belt 18, a collection box 20, a frame 14, wheels 13 and power The transmission assembly is composed; the shovel plate 5 is installed at the front position under the frame 14; the sieve-type sieve conveyor belt 9 is installed on the frame 14, and its front end is located at the rear of the shovel plate 5, and the rear end leads to Screen cage 17; the screen cage 17 is mounted on the top of the frame 14 rear through the rotating shaft, and the digging plate 15 is housed in the screen cage 17; the collection box 20 is mounted on the frame 14 and is located Above; the conveyor belt 18 is installed above the collection box 20 and passes into the screen cage 17; the wheels 13 are installed under the frame 14; the front of the frame 14 is equipped with a traction frame 1, a power transmission main shaft 22 and a gearbox 21 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com