Adjuvant material formula for preparing lactobacillus pepper and preparation method of product thereof

A technology for lactic acid bacteria and pepper products, which is applied in the fields of biotechnology and food, can solve the problems of poor quality change of kimchi raw materials, unstable flavor and quality, limited quantity and scale, etc., so as to achieve controllable product quality, shorten maturation time, and reduce harmful components. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

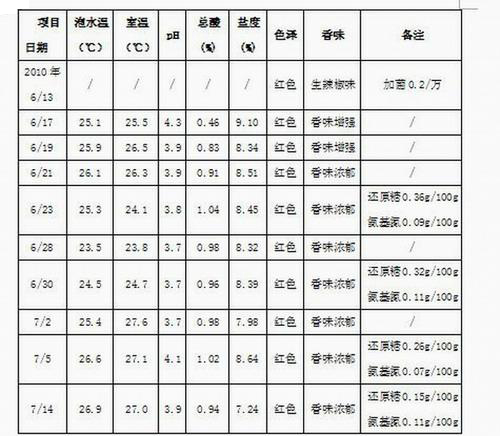

Image

Examples

Embodiment 1

[0034] The making of embodiment 1 pool bubble pepper

[0035] 6600kg of fresh red pepper, 600kg of iodine-free salt, 3000kg of salt water (prepared salinity requires a concentration of 10% by weight), 6.6kg of calcium lactate, and an activation solution prepared from 300g of paulome lactic acid bacteria preparation. Sprinkle salt while adding fresh chili peppers. After the chili peppers and salt are mixed and added, seal the pool, place plastic interlayers and bamboo woven mats, and press stones. Then add salt water, submerge the peppers for 15-20cm, and use salt water to drain the water. Calcium lactate is added after melting, mixed evenly, and the maturation period is 30 days.

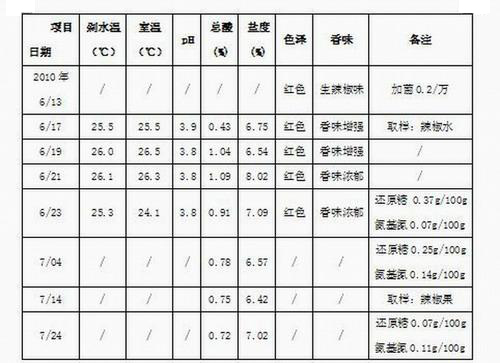

Embodiment 2

[0036] The making of embodiment 2 bucket bubble pepper

[0037] 20kg of fresh green peppers, 35kg of salt water (13.5% by weight is required for the preparation of salinity), 20g of calcium lactate, 140g of citric acid, and an activation solution prepared from 0.8g of Paulome lactic acid bacteria preparation. Put the fresh peppers into a cleaned plastic bucket, then add the prepared salt water, add all the auxiliary materials into the salt water, cover the surface with a plastic film, press all the peppers into the soaking water with bamboo sticks to ferment, and the maturity cycle is 25-30 days .

Embodiment 3

[0038] Example 3 Production of Poached Chopped Pickled Peppers

[0039]Chop 100kg of fresh red peppers into 3-5mm*3-5mm granules, add 9kg of iodine-free salt, 200g of calcium lactate, and an activation solution prepared from 2g of Paulome lactic acid bacteria preparation, mix well in a blender, and then add to the pickling pool Fermentation in the middle, the filling volume is 85% of the volume of the pickling tank, and then the tank is sealed for fermentation, covered with plastic interlayers, bamboo mats, flower glue cloth (woven bags that can bear a certain weight), pressed with stones or re-sealed with sand and sealed for fermentation, the maturity cycle 25-30 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com