Process for producing pyrethrum through subcritical continuous extraction

A subcritical, pyrethrum technology, used in solid solvent extraction, biocides, biocides, etc., can solve the problems of many solvent recovery times, large differences in the quality of crude extracts, and long recovery time, so as to shorten the production cycle. , The effect of reducing the number of concentrated recovery and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

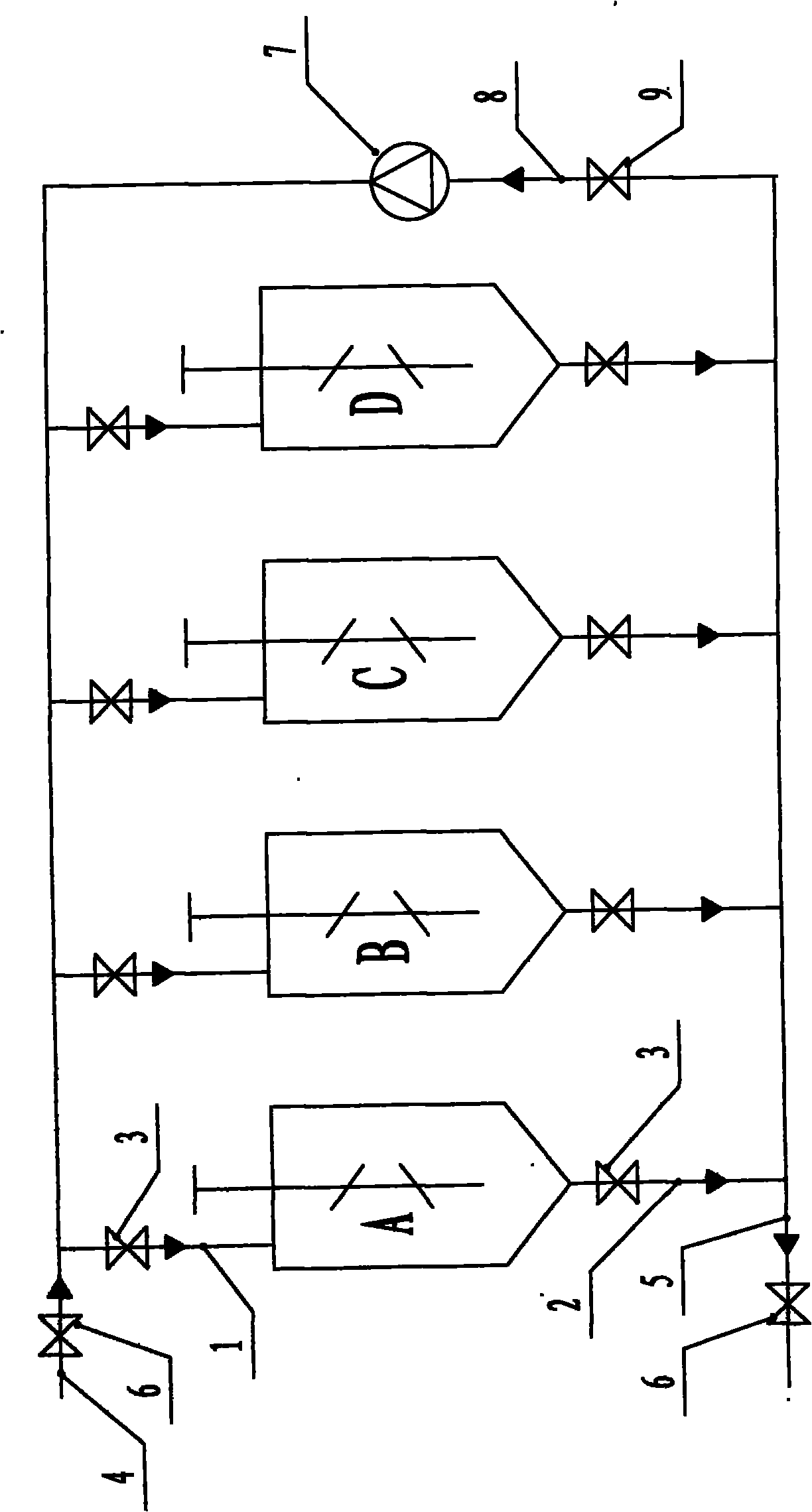

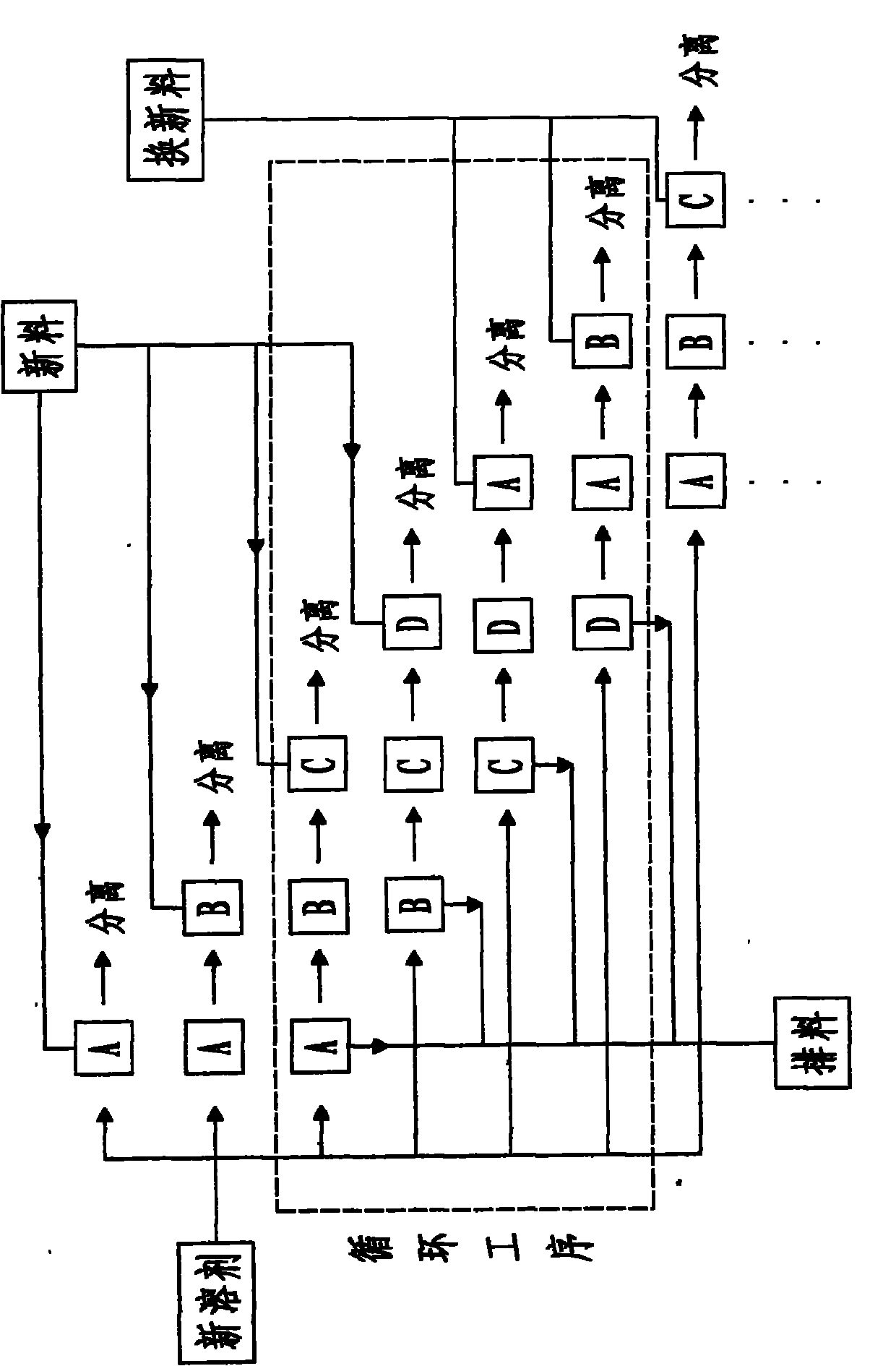

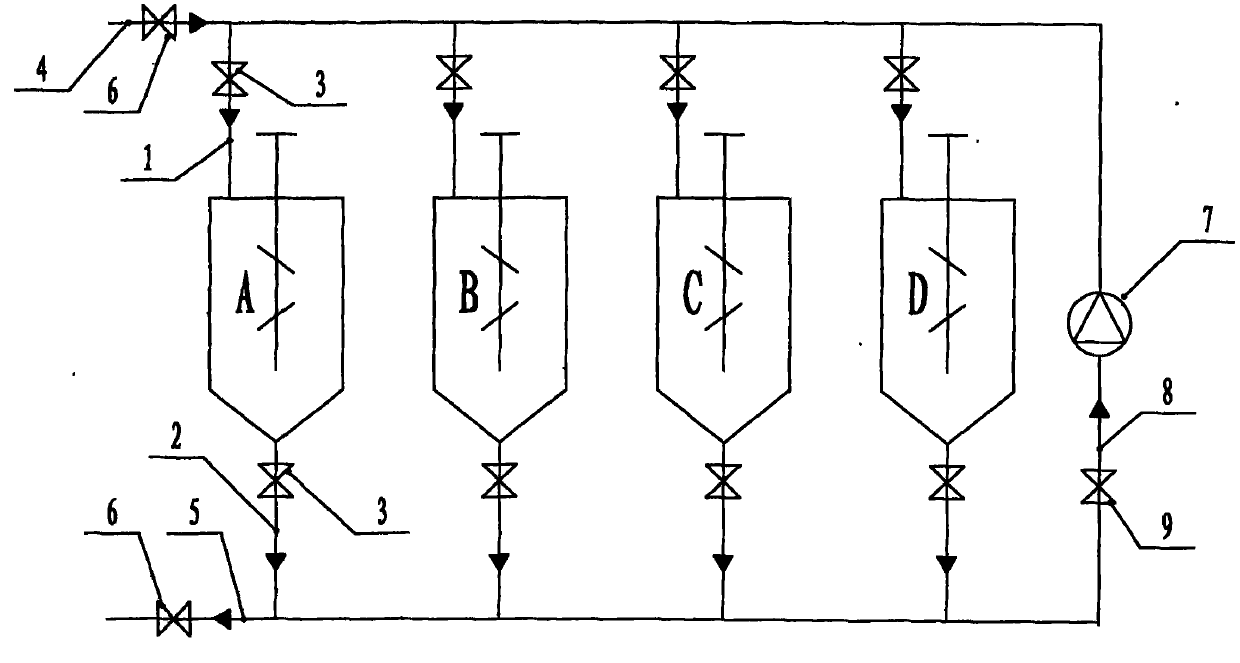

[0022] Embodiment: a kind of subcritical continuous extraction process of pyrethrum, the subcritical continuous extraction device used in this process is as figure 2 As shown, there are four extraction tanks, namely A tank, B tank, C tank and D tank. Each extraction tank is equipped with a liquid inlet pipe 1 and a liquid outlet pipe 2. On the liquid inlet pipe 1 and the liquid outlet pipe 2 Both are equipped with a stop valve 3, the liquid inlet pipe 1 on the extraction tank is connected with the solvent inlet pipe 4, the liquid outlet pipe 2 on the extraction tank is connected with the solvent outlet pipe 5, and the solvent inlet pipe 4 and the solvent outlet pipe 5 are connected. There is a main cut-off valve 6, and a solvent circulation pipe 8 is connected between the solvent inlet pipe 4 and the solvent outlet pipe 5, and the solvent circulation pipe 8 is equipped with a circulation valve 9 and a high-pressure pump 7;

[0023] The solvent used in this example is butane, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com