High phenyl siloxane rubber-based high-intensity, wide-temperature range and high-damping material

A silicone rubber, high phenyl technology, applied in the field of high-strength, wide-temperature and high-damping materials, damping rubber materials and additional damping treatment materials for structures, can solve the problems of inability to meet use requirements, low tensile strength, low damping factor, etc. Achieve significant vibration isolation and buffer effect, good mechanical properties, and the effect of less volatile matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Damping material ratio (mass percentage):

[0038] High phenyl silicone rubber 87.7%,

[0039] Peroxide vulcanizing agent 1.8%,

[0040] Mica flakes 8.7%,

[0041] Acrylic damping agent 1.8%.

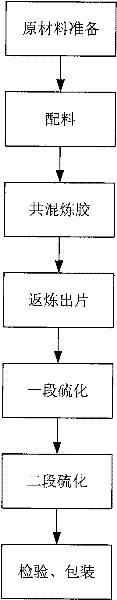

[0042] Preparation Process:

[0043] Add the peroxide vulcanizing agent into the high phenyl silicone rubber, then add mica flakes and acrylic damping agent, knead at 55°C, vulcanize at 165°C for 15 minutes after the sheet is released, and then heat up to 200°C within 40 minutes , keep warm for 4h and then cool down to room temperature naturally.

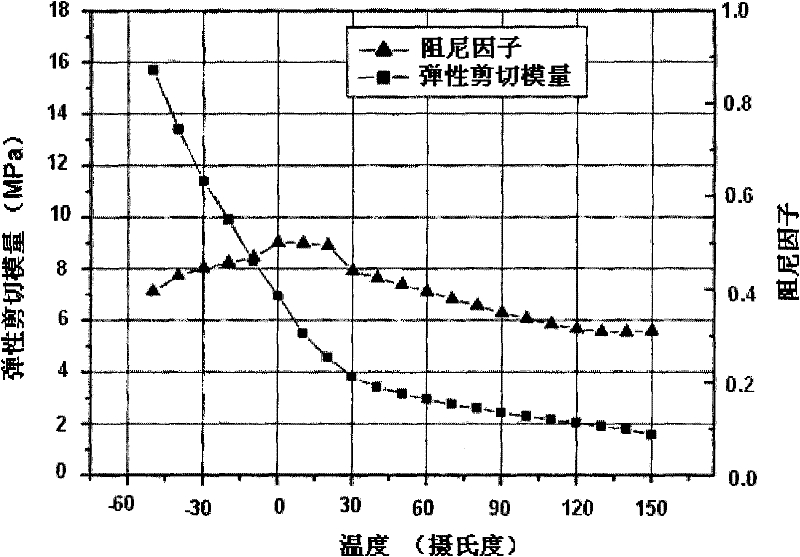

[0044] performance:

[0045] The tensile strength of the damping material in this example is 7.5MPa, the tear strength is 28.5MPa, the permanent deformation at break is 14%, and the damping factor β in the temperature range of -50~+150℃ max It is 0.41, and the shear modulus is greater than 2.4MPa.

Embodiment 2

[0047] Damping material ratio (mass percentage):

[0048] High phenyl silicone rubber 91.8%,

[0049] Peroxide vulcanizing agent 1.8%,

[0050] Mica flakes 4.7%,

[0051] Acrylic damping agent 1.7%.

[0052] Preparation Process:

[0053] Add the peroxide vulcanizing agent into the high phenyl silicone rubber, then add the mica sheet and damping agent, knead at 60°C, vulcanize at 170°C for 20min after the sheet is released, then raise the temperature to 200°C within 50min, and keep it warm for 4h Then cool down to room temperature naturally.

[0054] performance:

[0055] The tensile strength of the damping material in this example is 8.9MPa, the tear strength is 31.6KN / m, the permanent deformation at break is 16%, and the damping factor β in the temperature range of -50~+150℃ max It is 0.49, and the shear modulus is greater than 2MPa.

Embodiment 3

[0057] Damping material ratio (mass percentage):

[0058] High phenyl silicone rubber 96.2%,

[0059] Peroxide vulcanizing agent 1.9%,

[0060] Acrylic damping agent 1.9%.

[0061] Preparation Process:

[0062] Add the peroxide vulcanizing agent into the high phenyl silicone rubber, then add the damping agent, knead at 60°C, vulcanize at 175°C for 20 minutes after the tablet is released, then raise the temperature to 200°C within 60 minutes, keep it warm for 4 hours and then naturally Let cool to room temperature.

[0063] performance:

[0064] The tensile strength of the damping material in this example is 7.5MPa, the tear strength is 35KN / m, the permanent deformation at break is 22%, and the damping factor β in the temperature range of -50~+150℃ max is 0.5, and the shear modulus is greater than 2MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com