Metal arsenic reformer

A reformer and metal arsenic technology, applied in the field of high-purity arsenic production, can solve the problems of difficult quartz conversion tube, difficult flange hardness and brittleness, process failure, etc., and achieve the effects of low price, uniform thermal field, and improved conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

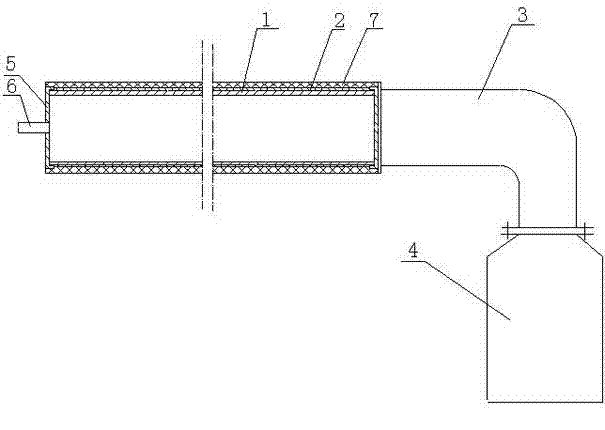

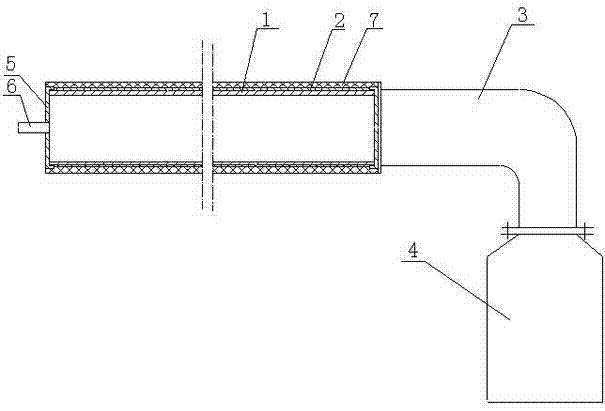

[0008] like figure 1 As shown, in the present invention, a heating layer 2 composed of electric heating wires is arranged outside the recrystallized silicon carbide conversion tube 1 , and a thermal insulation layer 7 is arranged outside the heating layer 2 . One end of the crystalline silicon carbide conversion pipe 1 is connected to the feed pipe 6 through the flange 5 , and the other end is connected to the aluminum storage tank 4 through the recrystallized silicon carbide connecting pipe 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com