Impregnating compound for basalt fiber filter felt

A technology of basalt fiber and filter felt, which is applied in fiber processing, textiles and papermaking, etc., can solve problems such as the harsh working environment of basalt fiber filter felt, achieve good social and economic benefits, improve product performance, improve temperature resistance and Effect of expiration date

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Graphite emulsion with a solid content of 20% 5%

[0015] PTFE solution with 60% solid content 8%

[0016] Silicone oil emulsion (SE-2203) with a solid content of 60% 5%

[0017] Polyacrylate emulsion (LI-3) with a solid content of 30% 4%

[0018] water balance

Embodiment 2

[0020] Graphite emulsion with a solid content of 20% 6%

[0021] PTFE solution with 60% solid content 10%

[0022] Silicone oil emulsion (SE-2203) with a solid content of 60% 6%

[0023] Polyacrylate emulsion (LI-3) with a solid content of 30% 5%

[0024] water balance

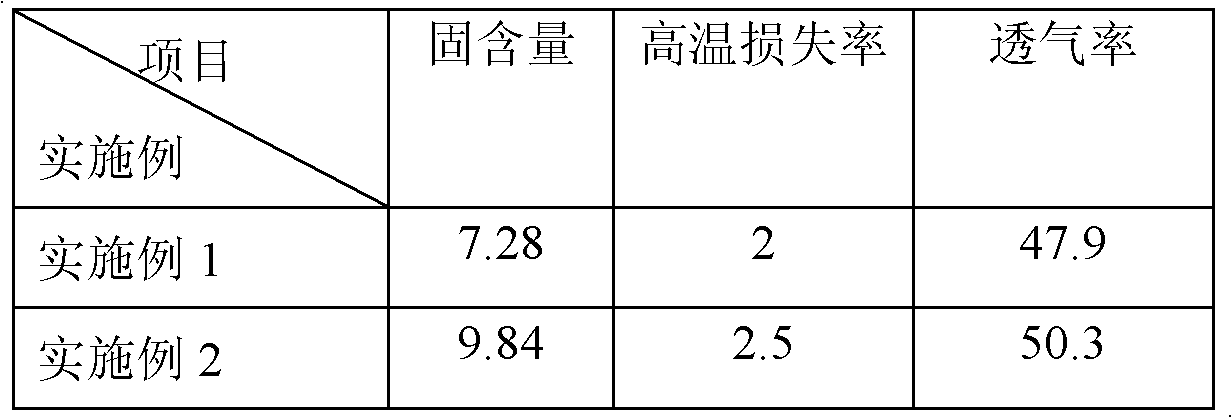

[0025] The following are the test results: (both in percentage)

[0026]

[0027] It can be seen from the test results that after using the surface-coated basalt fiber filter felt of the present invention, the high-temperature loss rate of the basalt fiber filter felt is greatly reduced, and the high-temperature resistance performance is greatly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com