Working sealing device for water turbine spindle

A technology for sealing devices and water turbines, which is applied in engine sealing, hydroelectric power generation, mechanical equipment, etc. It can solve the problems of no self-compensation, fast wear of the contact surface of the sealing block, etc., and achieve lower bearing height, good sealing performance, and reduced maintenance The effect of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

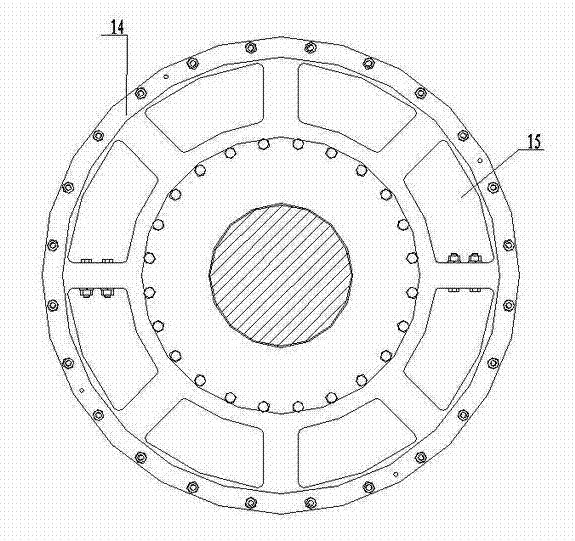

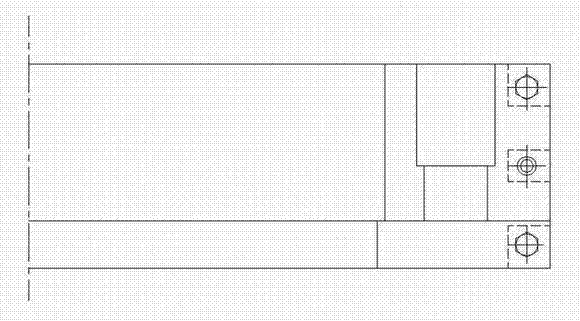

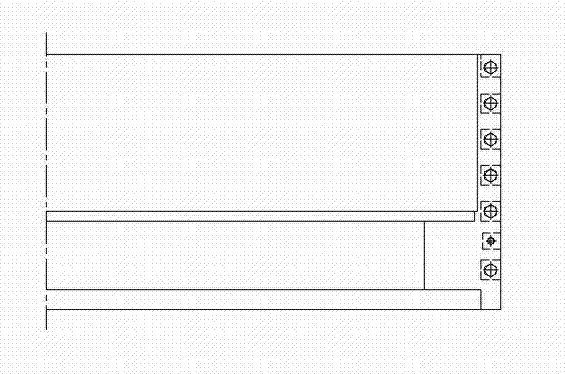

[0015] Such as Figure 1 to Figure 4 As shown, in the embodiment of the hydraulic turbine main shaft working sealing device provided by the present invention, it includes a sealing block 2, a sealing block 2 and an anti-wear ring 1, a sealing box 5, a decompression drain pipe 7, a sealing cover 8 and an air shroud 10 Together they form a sealing mechanism, the sealing block 2 below the anti-wear ring 1 is sleeved on the upper end of the positioning screw 3 in the sealing box 5, the lower end of the positioning screw 3 is fixed on the bottom of the sealing box 5, the pressure water inlet pipe 4 and the bottom of the sealing block 2 The cavity of the sealing box 5 is connected, and the anti-wear ring 1 and the sealing block 2 below are in close contact and fit under the action of the water inlet pressure of the pressure inlet pipe 4. The sealing box 5 is installed above the sealing cover 8, and the decompression drain pipe 7 is connected to the sealing cover. The labyrinth groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com