High-power light-emitting diode (LED) lamp

An LED lamp, high-power technology, applied in the field of electric light source, can solve the problem of aluminum plate heat energy not being able to transfer quickly, and achieve the effect of reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

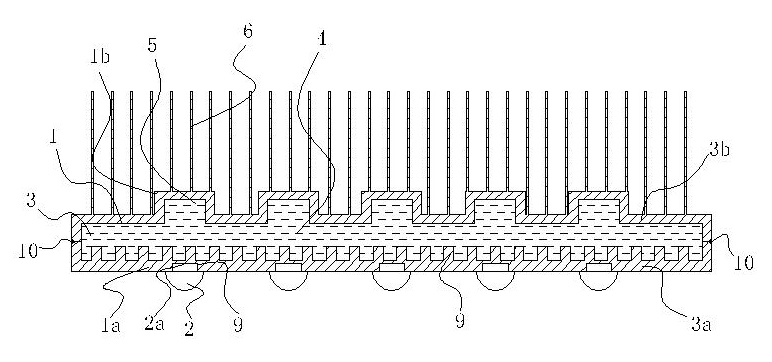

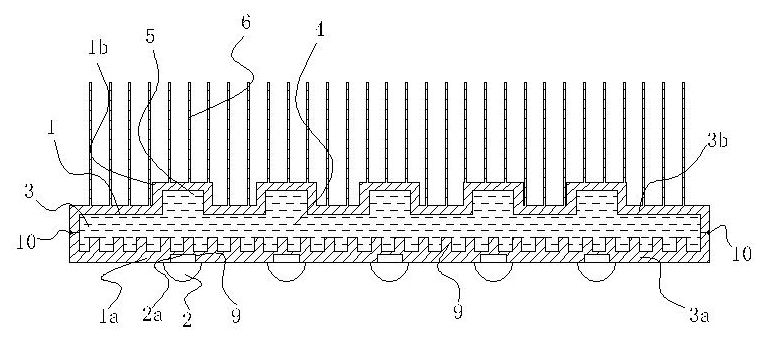

[0011] Embodiment 1: as figure 1 As shown, the present invention includes a heat dissipation plate 1, a heat dissipation surface 2a fixed on the front 1a of the heat dissipation plate 1 unit LED lamp 2, and its special feature is that the heat dissipation plate 1 is provided with an airtight cavity 3, and the airtight cavity 3 is provided with a high-efficiency The thermal energy transfer liquid 4 is provided with several grooves 5 on the side of the closed cavity 3 away from the unit LED lamp 2 . In order to speed up the heat dissipation speed of the unit LED lamp 2 to the heat dissipation plate 1 , the heat dissipation surface 2 a of the unit LED lamp 2 is embedded in the inlay groove 9 of the heat dissipation plate 1 . Radiation fins 6 are provided on the back surface 1b of the heat dissipation plate 1 . Several sheet-shaped protrusions 9 are provided on the side close to the unit LED lamp 2 in the closed cavity 3 to increase the heating area of the high-efficiency h...

Embodiment 2

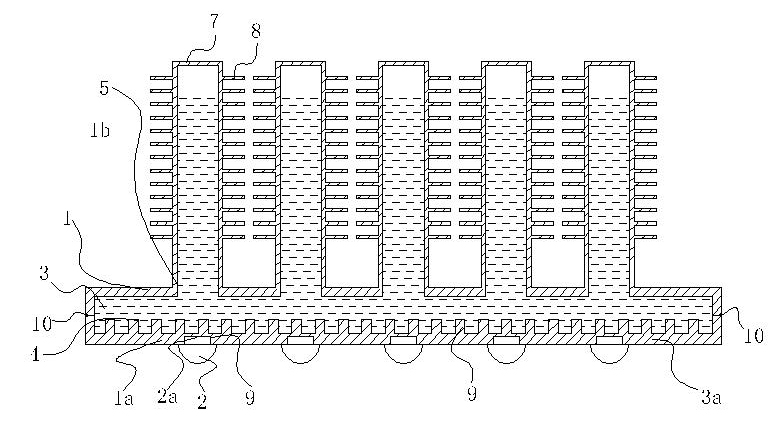

[0012] Embodiment 2: as figure 2 As shown, the present invention includes a heat dissipation plate 1, a heat dissipation surface 2a fixed on the front 1a of the heat dissipation plate 1 unit LED lamp 2, and its special feature is that the heat dissipation plate 1 is provided with an airtight cavity 3, and the airtight cavity 3 is provided with a high-efficiency The thermal energy transfer liquid 4 is provided with several grooves 5 on the side of the closed cavity 3 away from the unit LED lamp 2 . Several heat pipes 7 are arranged on the back side 1 b of the heat dissipation plate 1 , and the heat pipes 7 communicate with the grooves 5 on the inner cavity 3 of the heat dissipation plate 1 . Several cooling fins 8 are arranged on the heat pipe 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com