Method for measuring combustion heat value of boron powder

A measurement method and calorific value technology, which is applied in the field of determination of combustion calorific value, can solve problems such as incomplete combustion of boron powder, and achieve good application prospects, convenient operation, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

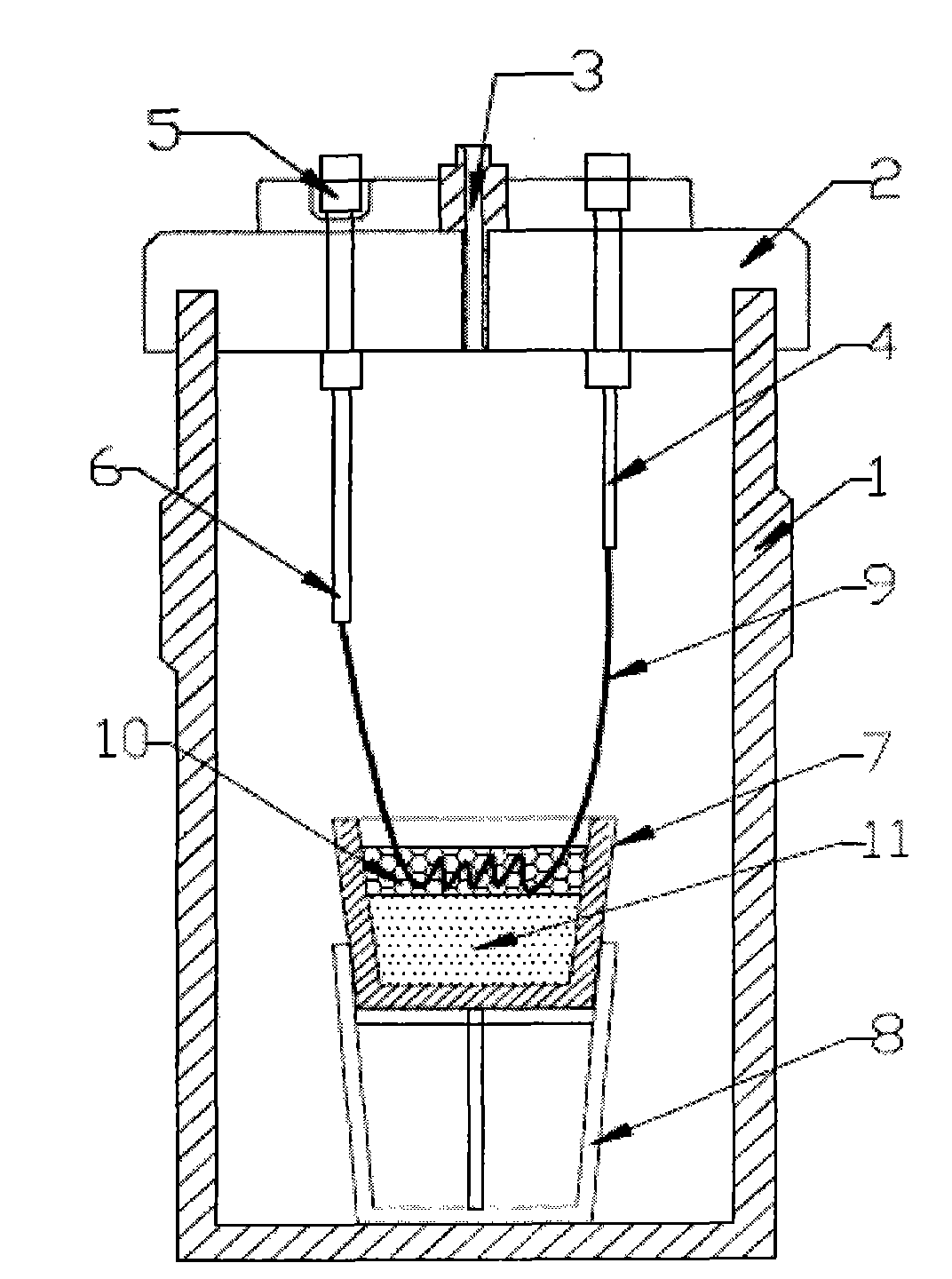

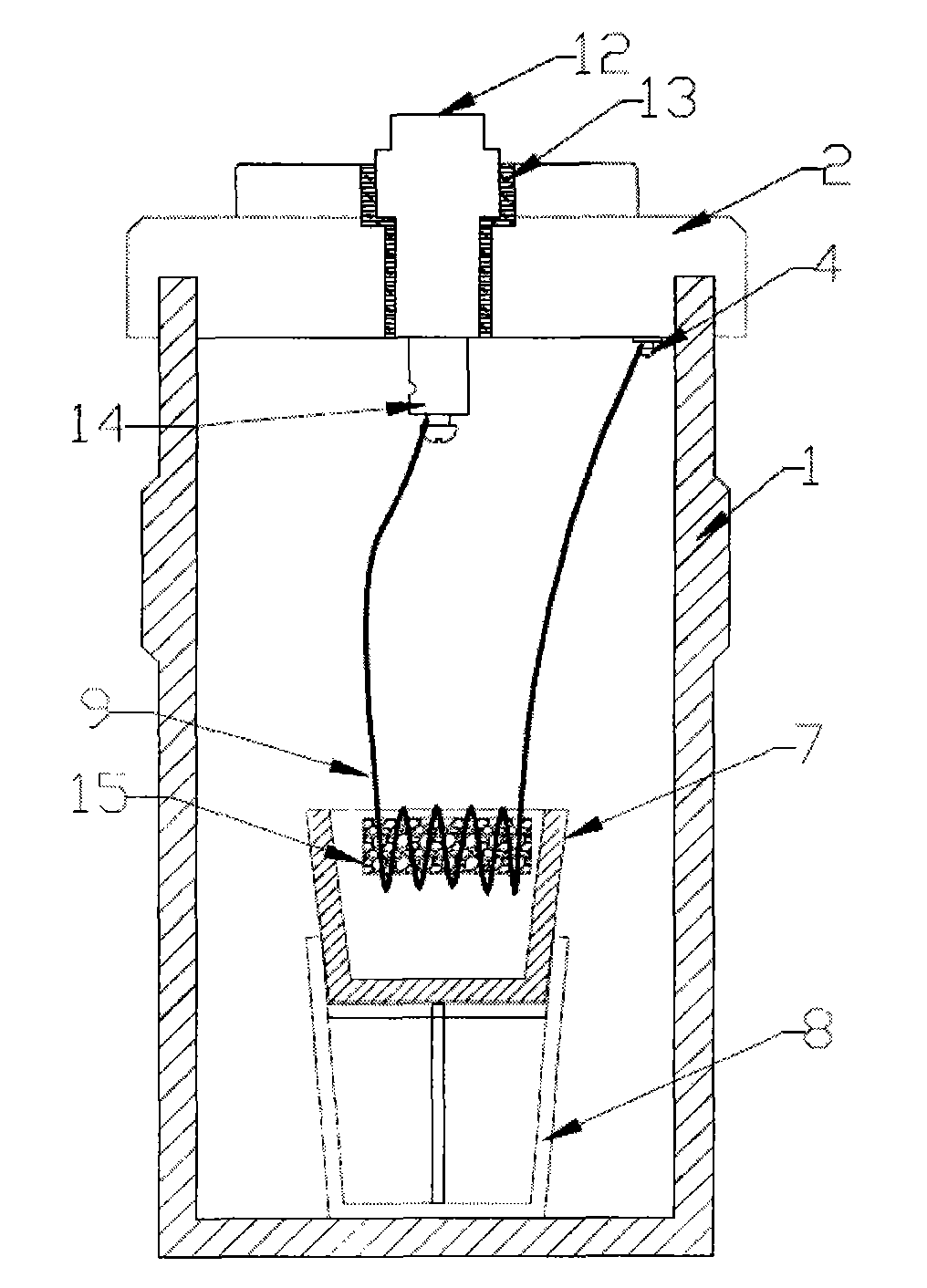

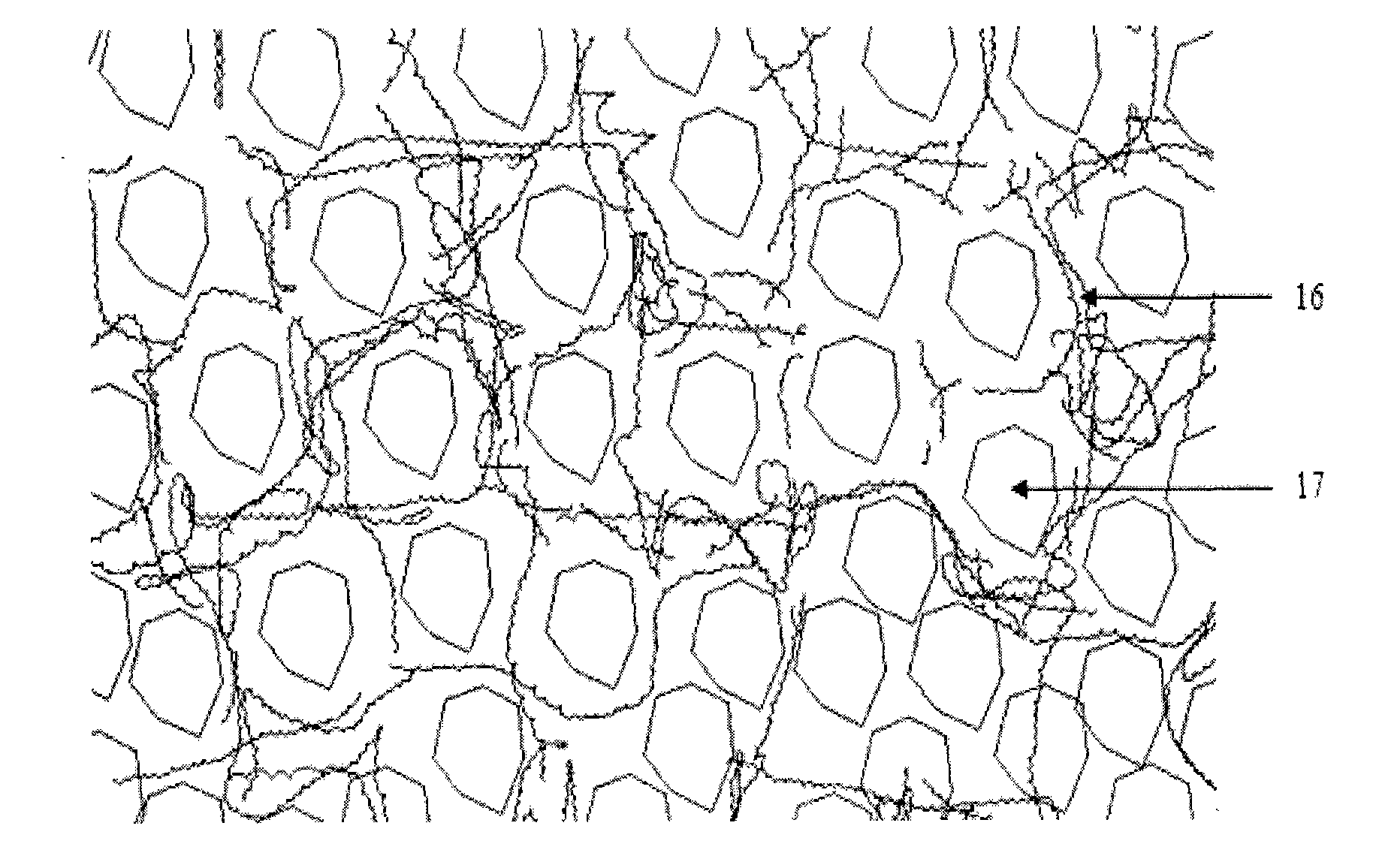

[0033] figure 2 The improved device of this test method is shown. The device is made of the YDI-00 oxygen bomb produced by Changsha Kaiyuan Instrument Co., Ltd. after the crucible suspension structure is removed, and then screws are added. image 3 It shows the structure of intermolecular mixing of SQ-2 combustion accelerant dissolved in acetone and boron powder particles in the present invention, Figure 4 The photo taken with a high-power electron microscope shows the structure of the SQ-2 combustion accelerant that has not been dissolved in acetone in a granular form and mechanically mixed with boron powder particles. Figure 5 The device connection structure of this test method is shown. This device is based on the GR3500 oxygen bomb calorimeter manufactured by the Chinese state-owned Changsha Instrument Factory. The imaging processing system replaces the Beckman thermometer temperature system in the GR3500 that was originally recorded by manual reading.

[0034] The pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| combustion efficiency | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com