Method for optimizing 'hot metal can of system' interface mode in blast furnace-converter section in steel enterprise

A converter and blast furnace technology, applied in the field of metallurgical process technology and computer simulation, optimization of design and layout of the general plan, optimization of the "one tank to the bottom" interface mode of the blast furnace-converter section of iron and steel enterprises, to shorten the waiting time, The effect of increasing the temperature of molten iron entering the converter and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

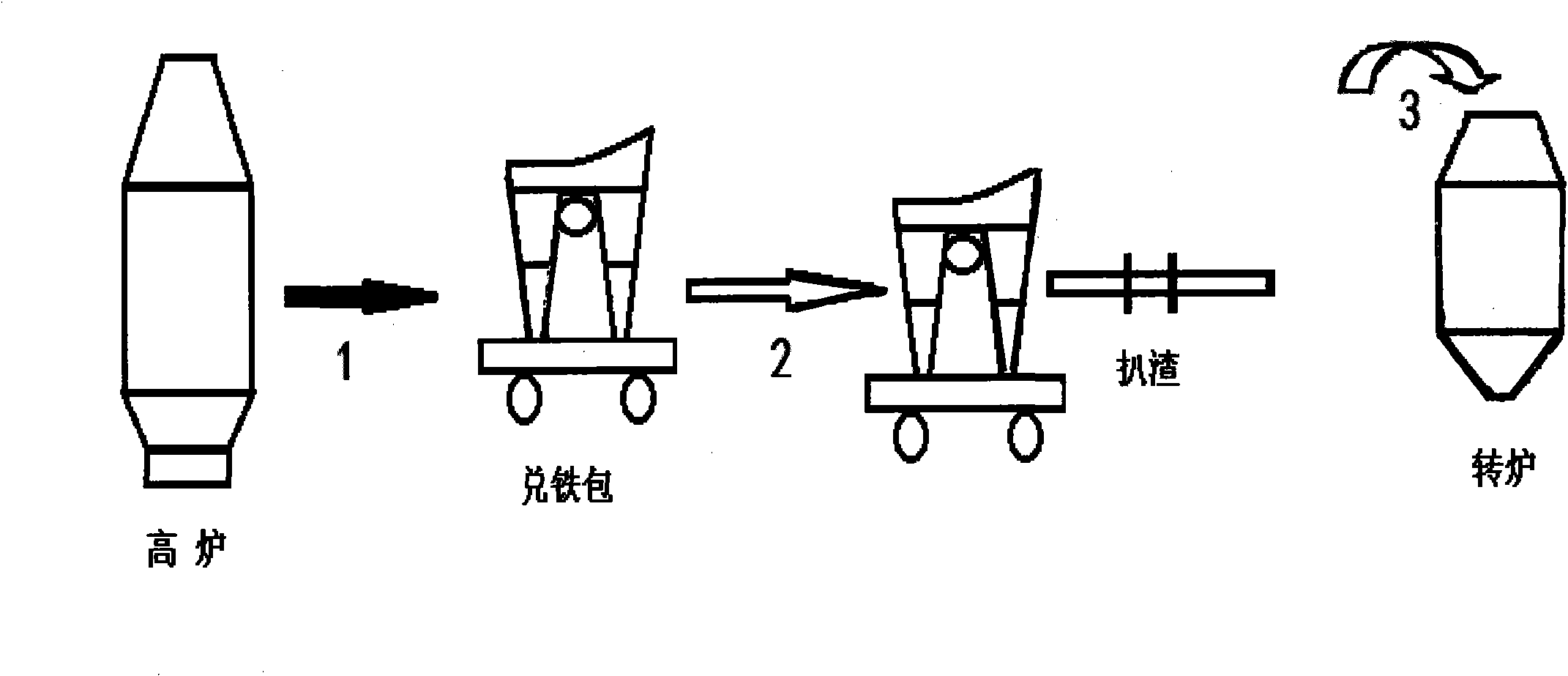

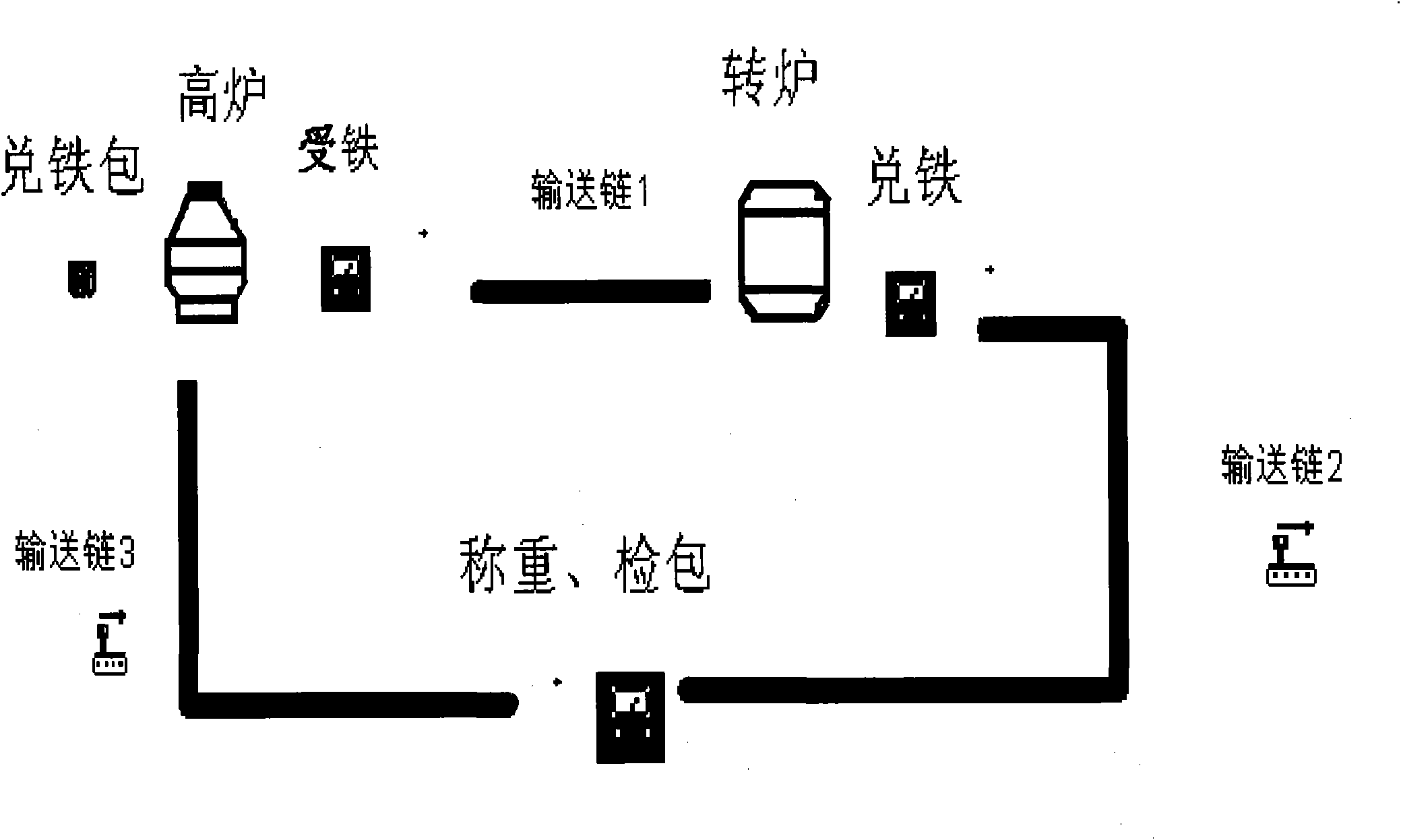

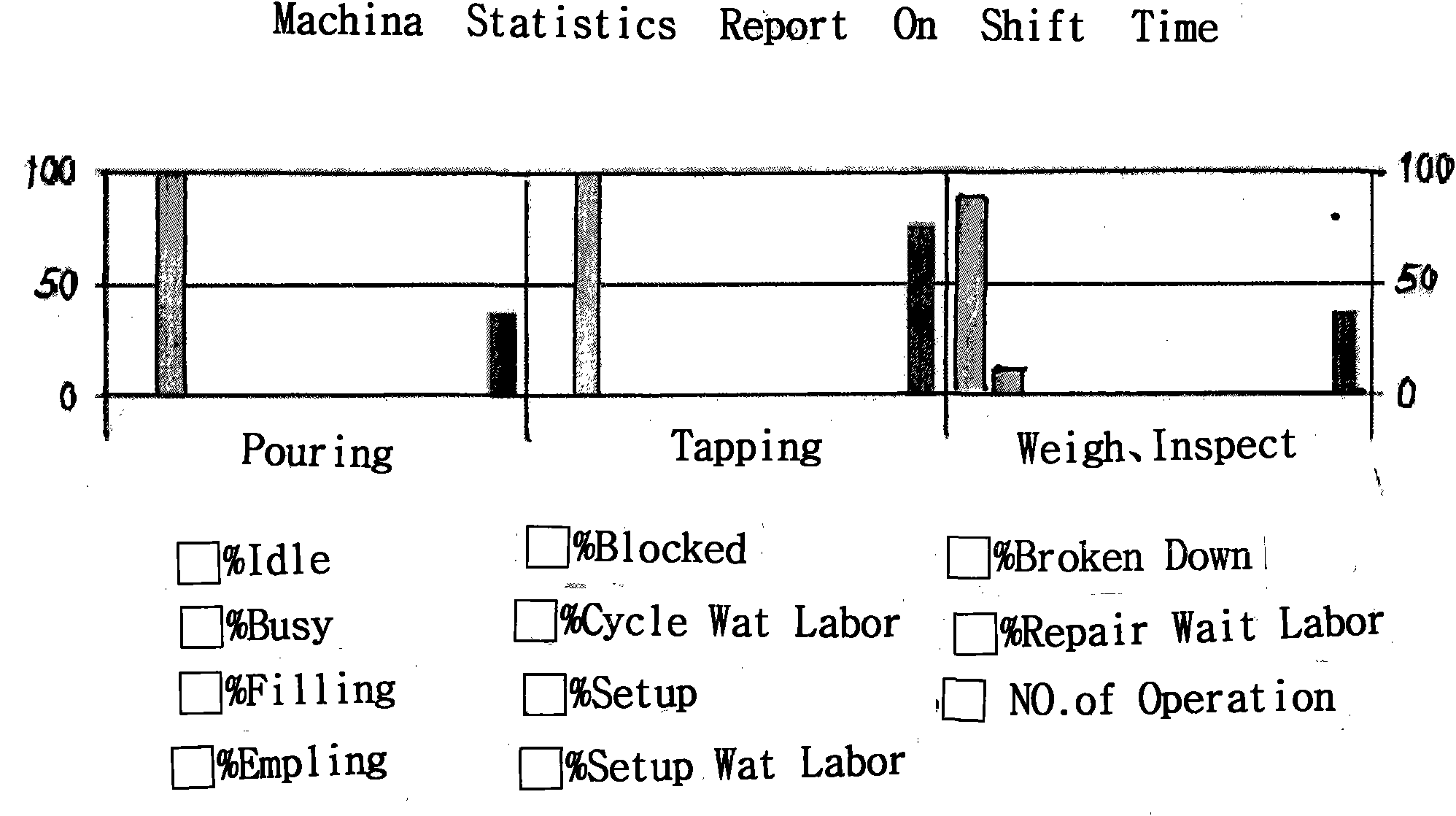

[0024]Example 1: Firstly, on-site static collection of related data of the actual blast furnace-converter section "one tank to the bottom" interface mode of a certain iron and steel enterprise, such as blast furnace tapping time, converter smelting cycle, transportation time, weighing or inspection time, Statistical data such as the arrival / departure of several cans per car, arrival / departure time intervals, etc., and the establishment of a physical model of the "one tank to the bottom" interface mode of the blast furnace-converter section, such as figure 1 . Then process and analyze the data collected on site, use computer simulation software to establish a computer simulation model of the "one tank to the bottom" interface mode of the blast furnace-converter section, and use the analyzed data in the computer simulation model to simulate steel The actual production situation of the blast furnace-converter section of the enterprise; use computer simulation software to define t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com