Clean flue gas circulation system

A circulating system and clean flue gas technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve problems such as affecting the normal operation of the boiler and unable to effectively control the return volume of clean flue gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

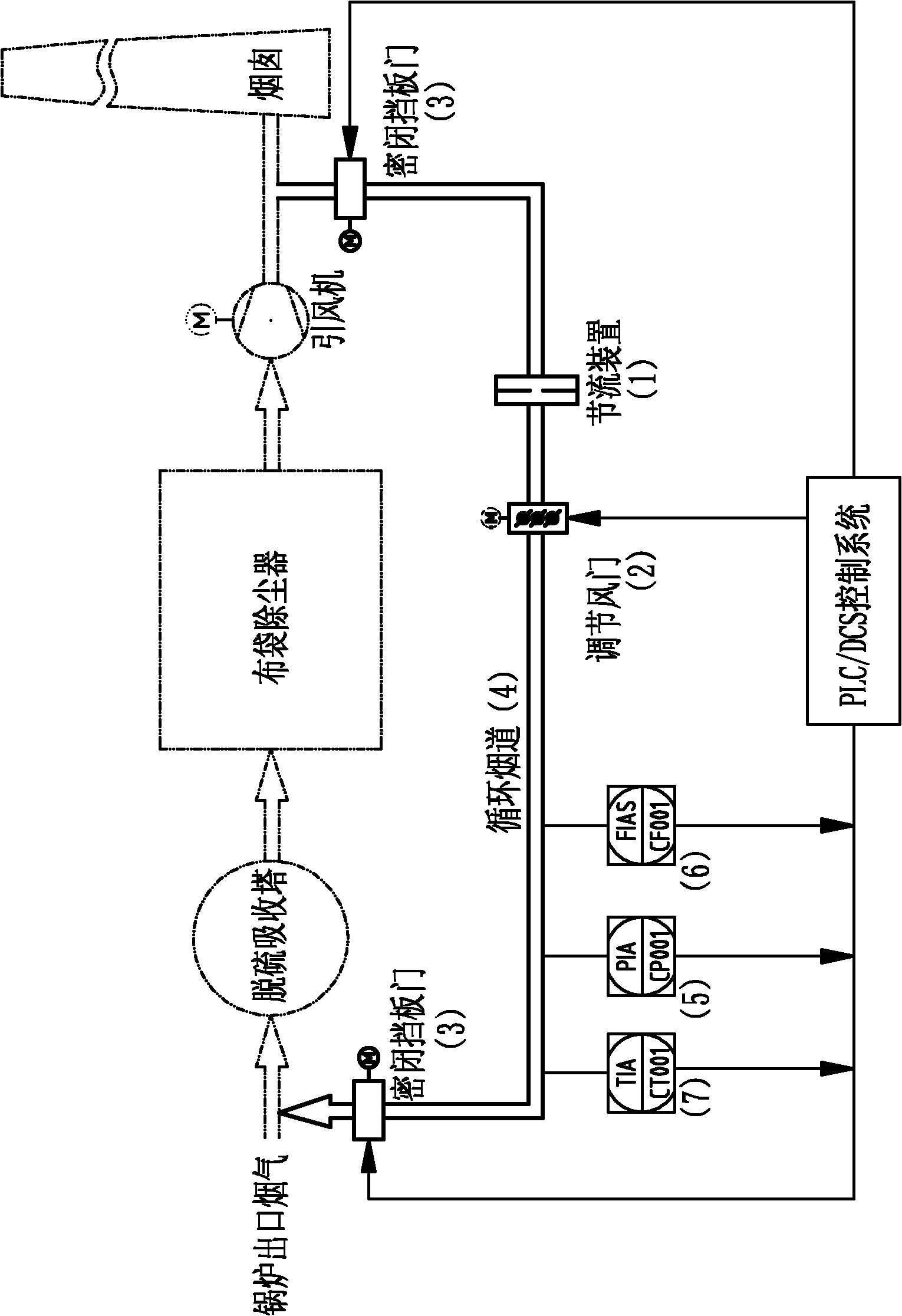

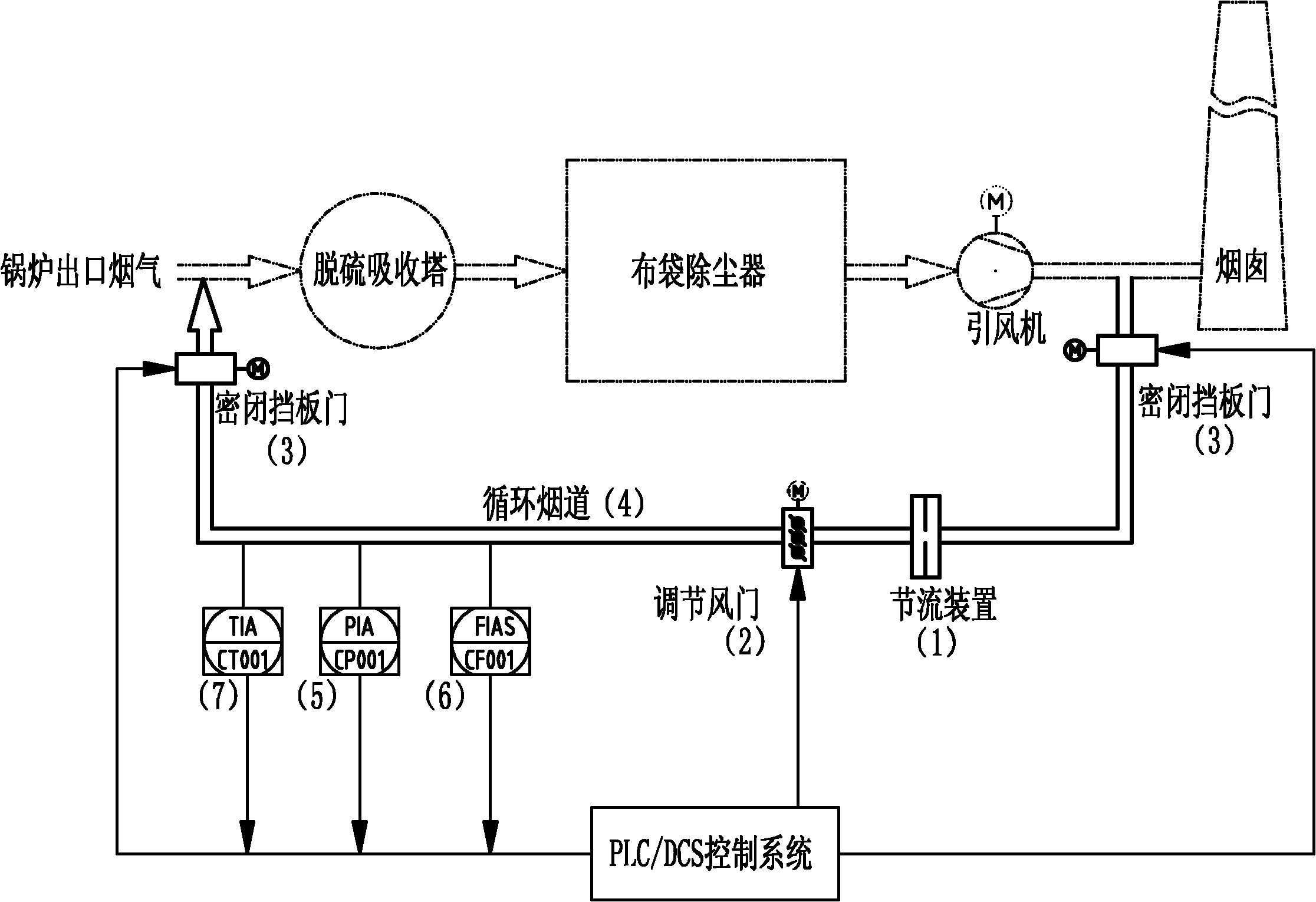

[0016] refer to figure 1 , a clean flue gas circulation system of the present invention includes a control system and a circulation flue 4, and the circulation flue 4 is arranged between the outlet end of the induced draft fan and the inlet end of the desulfurization absorption tower, and is characterized in that The circulating flue 4 is provided with a first airtight baffle door 3, a throttling device 1, a damper 2, a gas flow meter 6, a gas pressure gauge 5, a gas thermometer 7 and a second airtight baffle door 3 in sequence. The input end of the control system is connected to the output end of the gas pressure gauge 5, the gas flow meter 6 and the gas thermometer 7, and the output end of the control system is connected to the control ends of the two airtight damper doors 3 and the damper 2.

[0017] The throttling device 1 is a circular orifice plate or a Venturi throttling device, which plays a role of throttling and damping when the net flue gas circulation system is tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com