Side hole forming and deep drawing type progressive die

A technology of progressive die and side hole, which is applied in the field of progressive die to achieve the effects of timely supply, high processing precision and good quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

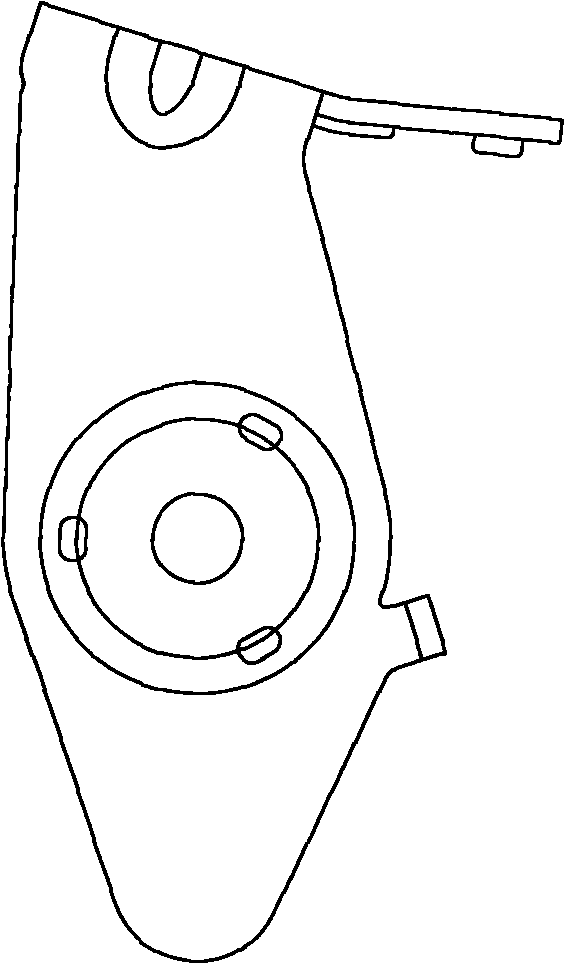

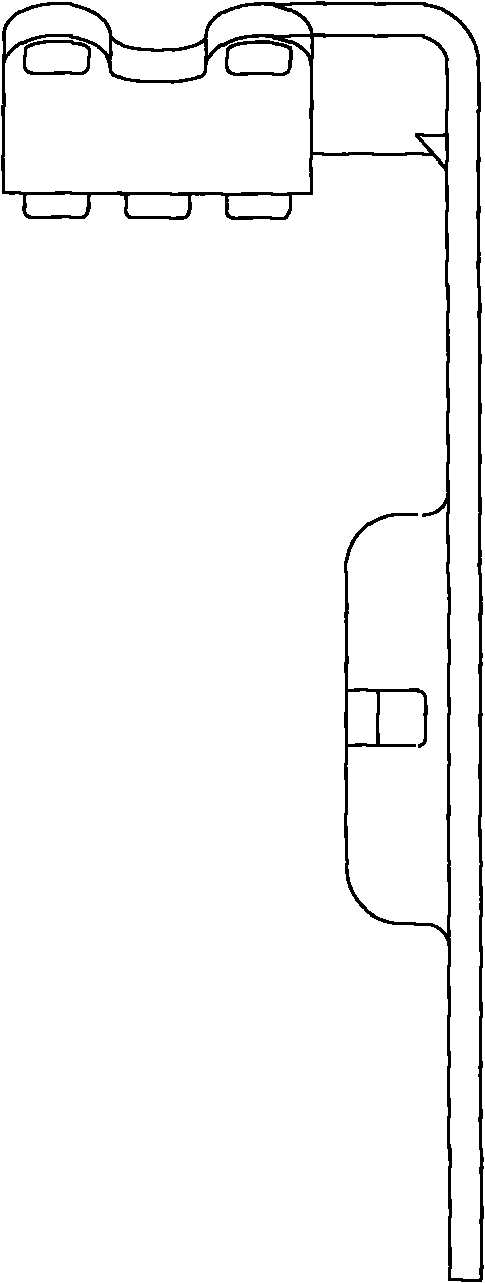

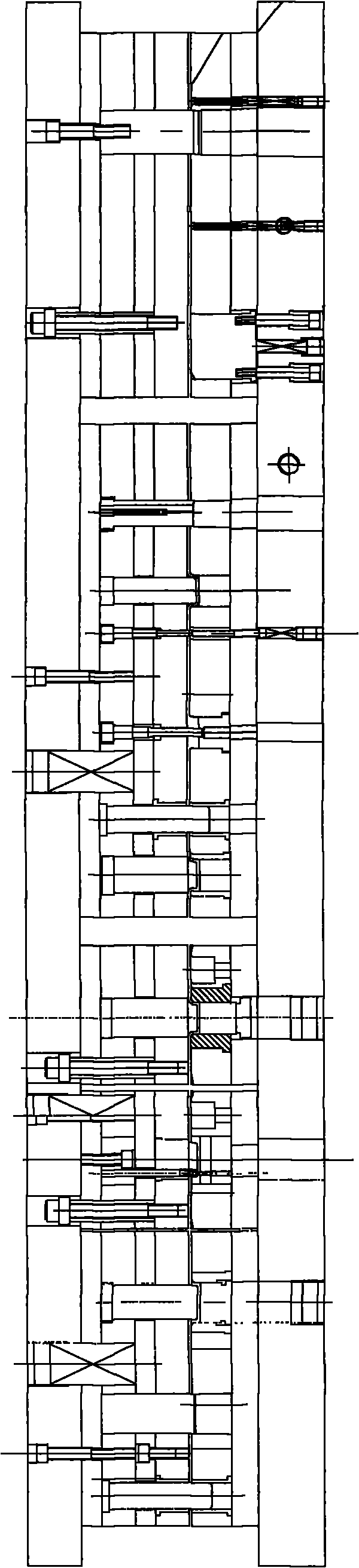

[0020] Example 1, such as image 3 As shown, this embodiment is a complete figure 1 , figure 2 The progressive die of the bracket shown is a type of progressive die for side hole forming and deep drawing. The whole progressive die includes a deep drawing device set in the drawing station to draw the material strip and the upper side hole on the side wall In the side hole forming device for forming, there is an empty station spaced between the drawing and punching and the punching and drawing. The punching guide hole and the process notch device are set on the station before the drawing device, The punching process notch device is provided at the station between the punching guide hole and the drawing device, and the shaping device is provided at the station between the second drawing device and the side punching device, The bottom surface pressing device set at the station of the side punching device is set, and the station after the bottom pressing device further includes an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com