Superposed-permanent-magnet-motor-based electrical vehicle drive control system

A permanent magnet motor, drive control technology, applied in electric braking systems, electric vehicles, motors, etc., can solve problems such as failure of regenerative braking function, achieve high-efficiency energy feedback, flexible braking methods, and high regenerative energy feedback efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

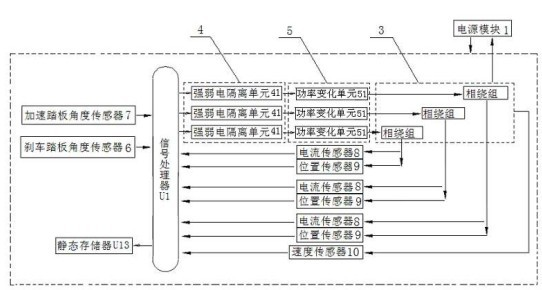

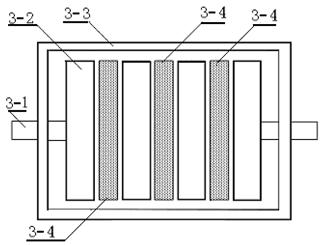

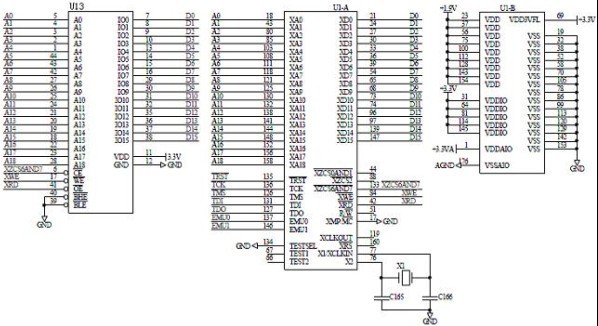

[0020] Example: such as figure 1 As shown, the present invention relates to a driving control system for an electric vehicle based on a superimposed permanent magnet motor: comprising a brake pedal and an accelerator pedal of the electric vehicle, a stacked permanent magnet motor 3 with three-phase windings, and a drive for driving the operation of the electric vehicle Modules, power supply module 1 with charging function, control module 2, strong and weak current isolation module 4, power conversion module 5, brake pedal angle sensor 6 installed on the brake pedal, accelerator pedal angle sensor 7 installed on the accelerator pedal, Three current sensors 8 for detecting the phase winding current, three position sensors 9 for detecting the position of the motor rotor, and a speed sensor 10 for detecting the speed of the motor, wherein the control module includes a signal processor U1 and is used to store The static memory U13 of the signal processor operation data, the two are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com