Antirust metal packing container and manufacturing method thereof

A technology of metal packaging and containers, which is applied in food packaging, transportation and packaging, and packaging of harmful substances. It can solve problems such as damage and affecting the quality of packaged goods, and achieve the effect of avoiding corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

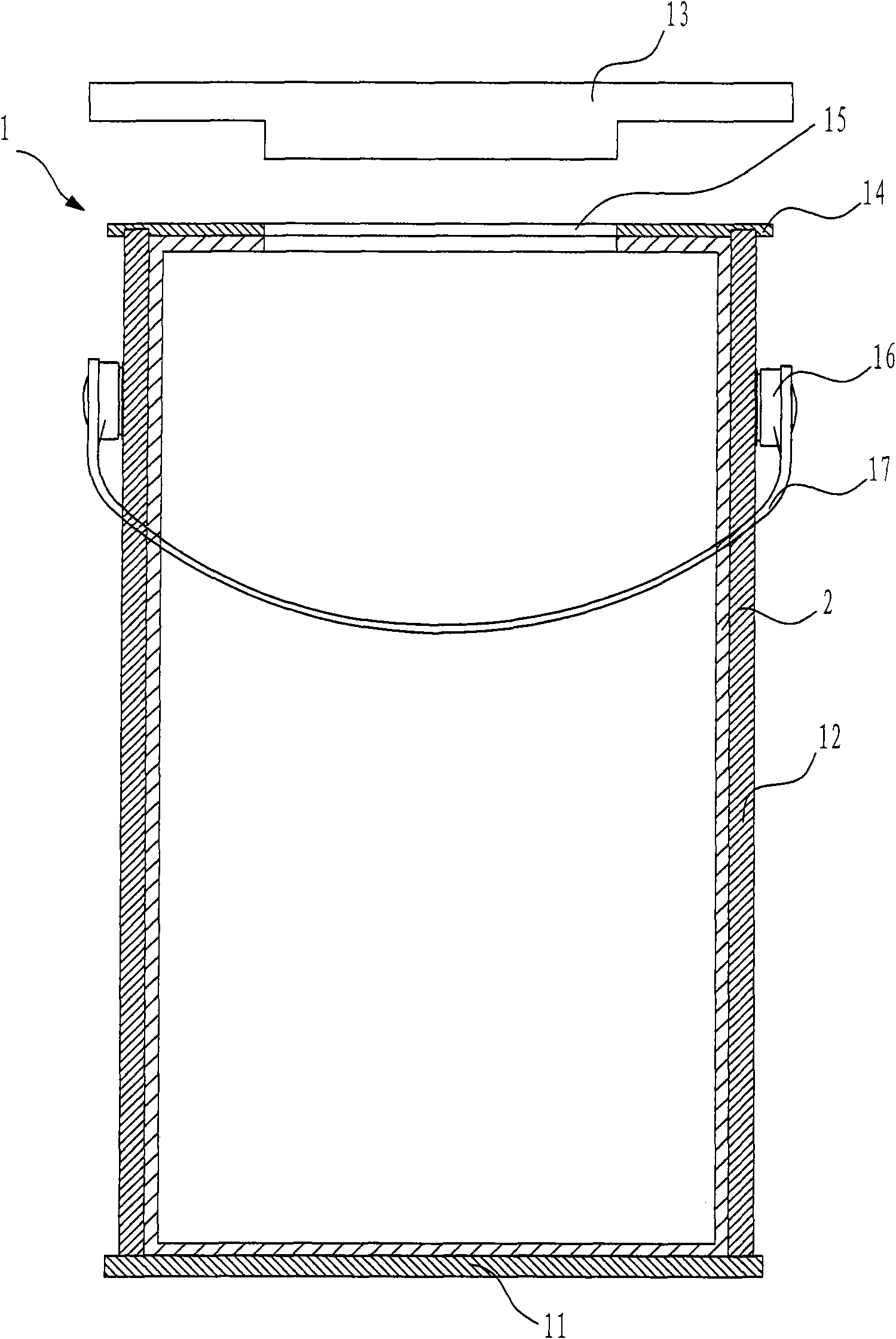

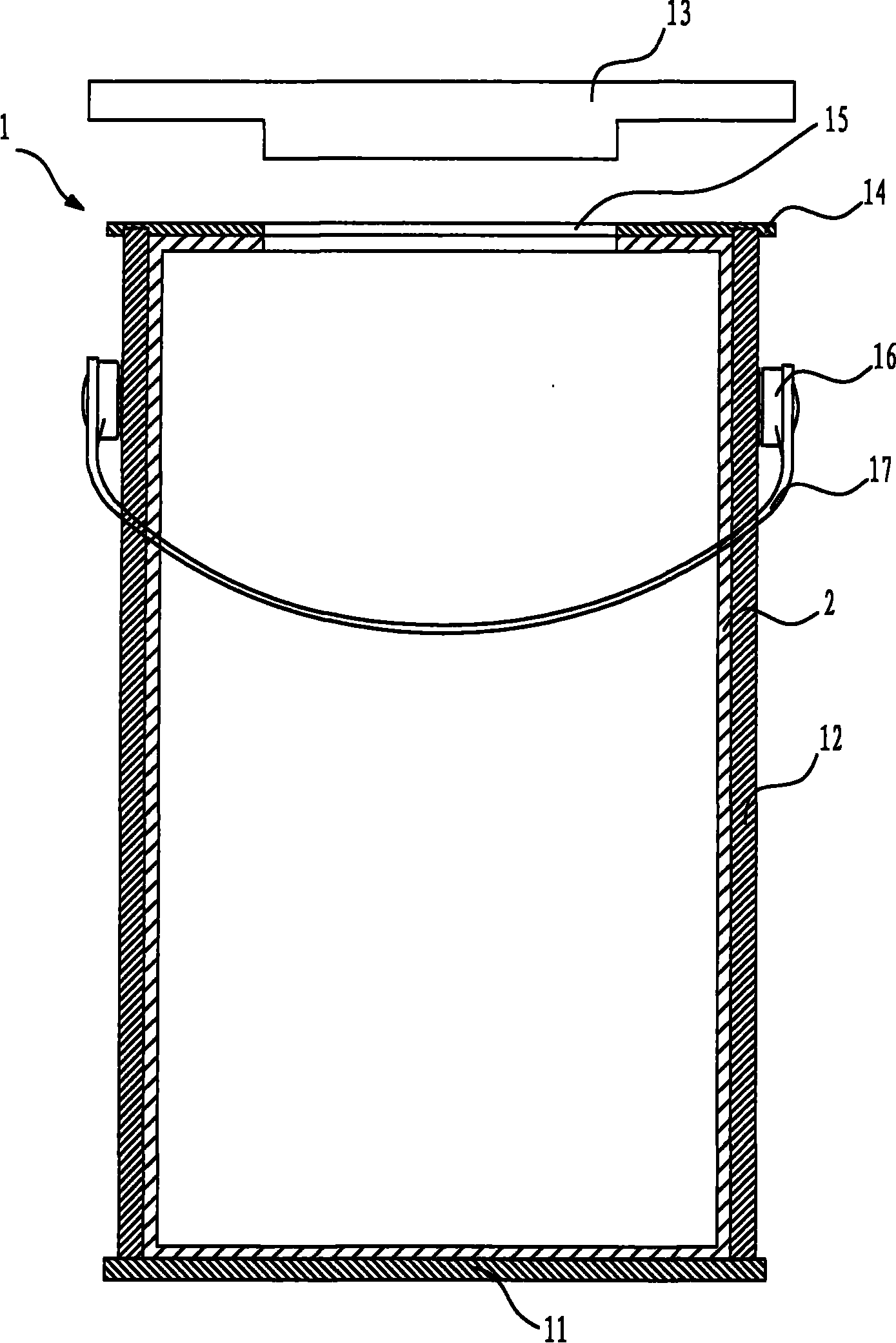

[0016] The technical scheme of the present invention will be further described below in conjunction with the embodiment shown in the accompanying drawings:

[0017] Such as figure 1 As shown, the packaging container includes a container body 1 made of tinplate. The container body 1 has a circular bottom 11 , a cylindrical body 12 and a circular lid 13 . The tank bottom 11 is installed on the bottom of the tank body 12, the top of the tank body 12 is sealed with a ring body 14, the inner side of the ring body 14 forms a tank opening 15, the tank cover 13 covers the ring body 14, and the outer wall of the tank body 12 is provided with a Butt welding ear 16, handle 17 is installed on this butt welding ear 16. The inside of the container body 1 has an anti-rust liner 2, which covers the inner wall of the container body 1, and the anti-rust liner 2 avoids direct contact between the goods to be packaged and the iron inner wall. Generally, the anti-rust liner 2 is made of PE. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com