Method for preparing graphene film

A technology of graphene film and graphite, which is applied in the field of graphene film preparation, can solve the problems of reduced electrical conductivity, etc., and achieve the effects of good conductivity, good reduction effect, and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In the first step, add 46mL of concentrated sulfuric acid to the Erlenmeyer flask and place it in an ice bath at 0±1°C, then slowly add 2g of expandable graphite and 1g of sodium nitrate, and then add 6g of potassium permanganate in four times (time interval After completion, move the Erlenmeyer flask to room temperature and place it for 16 hours (with constant stirring), then slowly and continuously add 92 mL of water with a syringe and raise the temperature to 98°C for 15 minutes; after the end, use warm water Dilute to 280mL, and add 6mL 30%wt hydrogen peroxide; the next step is to wash while hot, first wash 7 times with 5%wt dilute hydrochloric acid to remove sulfate ions, and then wash 7 times with deionized water to remove chloride ions And check with silver nitrate; finally, dry at 60°C for 15h;

[0022] In the second step, put the dry graphite oxide on the quartz boat and send it into the quartz tube, open the nitrogen valve, pass nitrogen gas into the quartz tu...

Embodiment 2

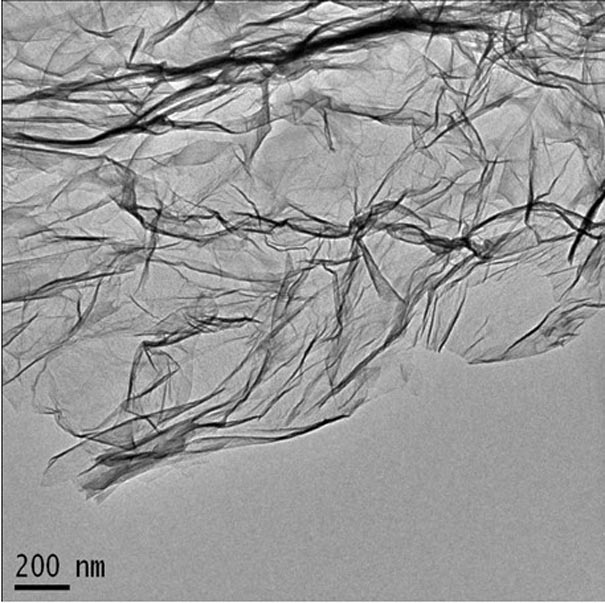

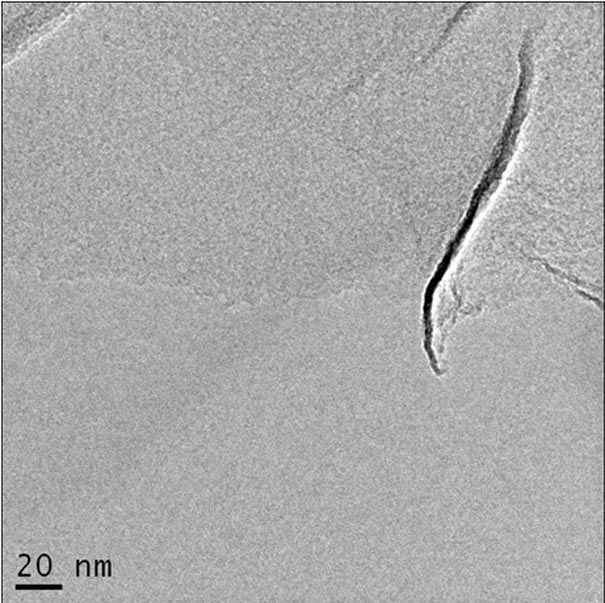

[0026] The preparation method is basically the same as in Example 1, except that graphite oxide is replaced by expanded graphite, and the reduced graphene obtained can be sprinkled on the water surface to obtain a similar figure 1 The results shown.

[0027]

Embodiment 3

[0029] The preparation method is basically the same as in Example 1, except that the quartz tube is not filled with nitrogen, but is evacuated to obtain graphene.

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com