Hydraulic oil and preparation method thereof

A hydraulic oil, flame retardant technology, applied in the petroleum industry, lubricating composition, etc., can solve the problems of reduced performance of seals, affecting the service life of hydraulic cylinder seals, slow temperature drop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the above-mentioned hydraulic oil is that the water glycol N46 and the SP846 fire-resistant hydraulic oil are uniformly mixed in a weight ratio of 100:3-7 to obtain the hydraulic oil of the present invention.

[0019] Wherein, the preferred weight ratio of water glycol N46 and SP846 fire-resistant hydraulic oil in the above-mentioned preparation method of hydraulic oil is 100:5.

Embodiment 1

[0021] Embodiment 1, preparation hydraulic oil of the present invention

[0022] Mix the aforementioned water glycol N46 and SP846 fire-resistant hydraulic oil in a weight ratio of 100:5, and put them into a 180L barrel for later use. The water glycol with the model number N46 was produced by Rongcheng Industrial Co., Ltd. of Panzhihua Steel City Group. Production date: January 2010. The fire-resistant hydraulic oil of model SP846 was produced by Rongcheng Industrial Co., Ltd. of Panzhihua Steel City Group. Production date: January 2010. The specifications of the raw materials are shown in Table 1.

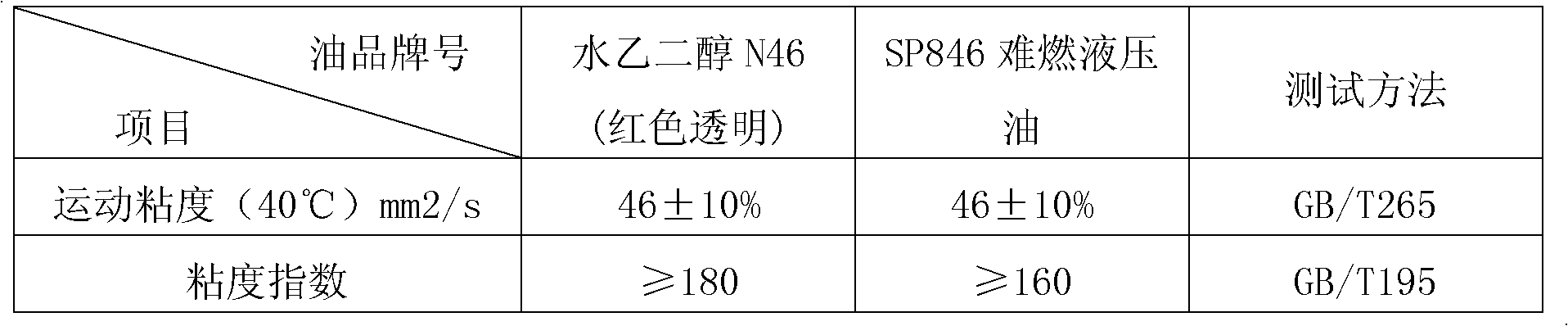

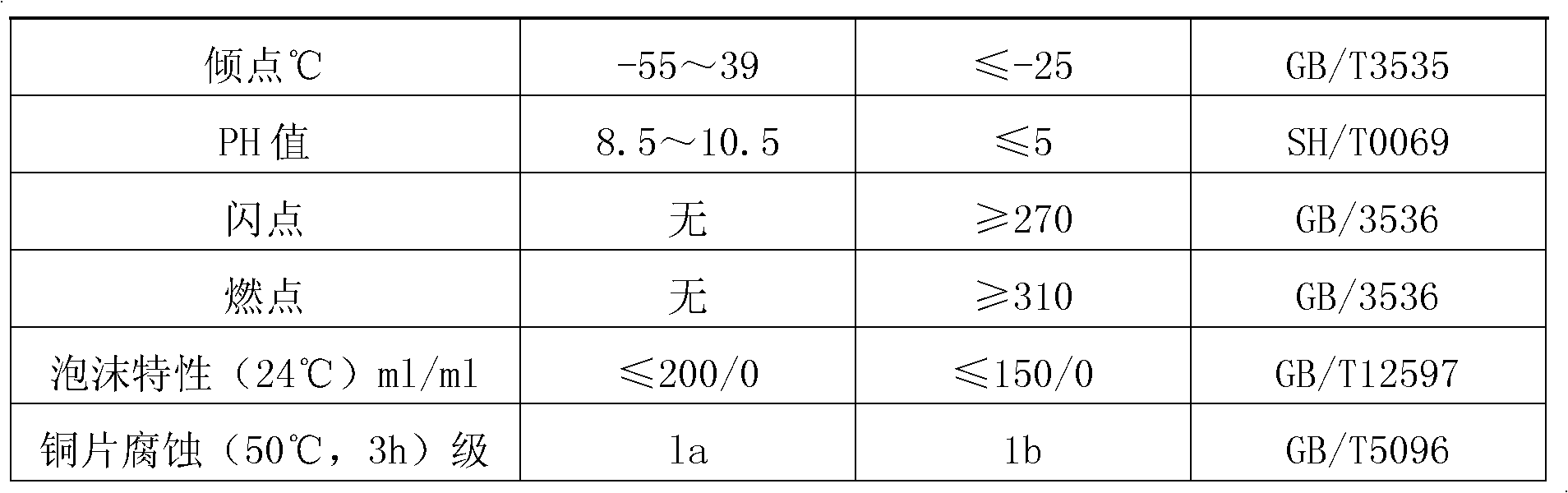

[0023] Table 1 Index table of water glycol N46, SP846 flame retardant hydraulic oil:

[0024]

[0025]

Embodiment 2

[0026] Embodiment two, using the hydraulic oil of the present invention as the hydraulic system oil

[0027] Between February and July 2010, the applicant worked on a set of hydraulic system (steelmaking electric furnace hydraulic system, the hydraulic oil equipment for this system mainly includes: 3 sets of hydraulic oil pumps; 25 sets of hydraulic valves; 12 sets of hydraulic oil cylinders ) The hydraulic oil prepared in Example 1 is used as the oil for the hydraulic system. The oil pump and hydraulic valve were not damaged within 6 months of using the oil, and the hydraulic system was cleaned and maintained 3 times on a regular basis. A total of 40 barrels of oil were used (180L per barrel). The cost of this hydraulic system was about 130,000 yuan during this time. The results show that the hydraulic oil has little damage to hydraulic system equipment, and has good anti-wear, lubricating, anti-rust, anti-corrosion and other functions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com