Membrane with uniform chroma

A technology of uniform chromaticity and thin film, applied in the direction of static indicators, etc., can solve the problem of color non-uniformity of etched and non-etched blocks without considering it, so as to reduce the yellowing phenomenon of thin film, uniform color, and reduce chromaticity poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and embodiments. It should be noted that in the following description, similar elements are denoted by the same numerals.

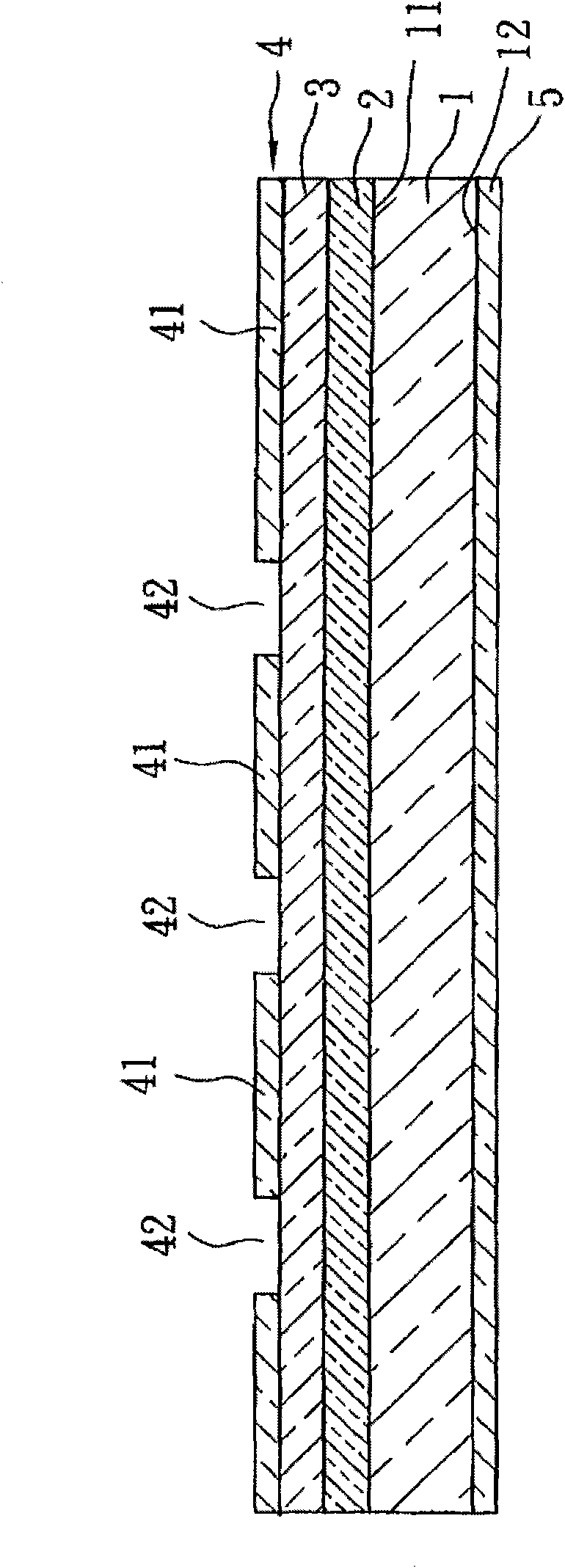

[0028] refer to figure 1 , Embodiment 1 of the film with uniform chromaticity of the present invention comprises: a base material 1, a surface treatment layer 5 coated on the surface of the base material 1, a second surface treatment layer coated on the other surface of the base material 1 A refraction layer 2 , a second refraction layer 3 covering the surface of the first refraction layer 2 , and a transparent conductive layer 4 covering the surface of the second refraction layer 3 .

[0029] The substrate 1 has a first surface 11 and a second surface 12 spaced apart in opposite directions. The material of the substrate 1 is, for example, polyethylene terephthalate (PET), polycarbonate (polycarbonate, PC), polyethylene (polyethylene, PE)... and oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com