Pressure-sensitive adhesive film

A technology of adhesive film and adhesive layer, which is applied in the direction of adhesives, film/sheet adhesives, adhesive products, etc., can solve problems such as insufficient performance, and achieve excellent processing adaptability, less adhesion, and excellent viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

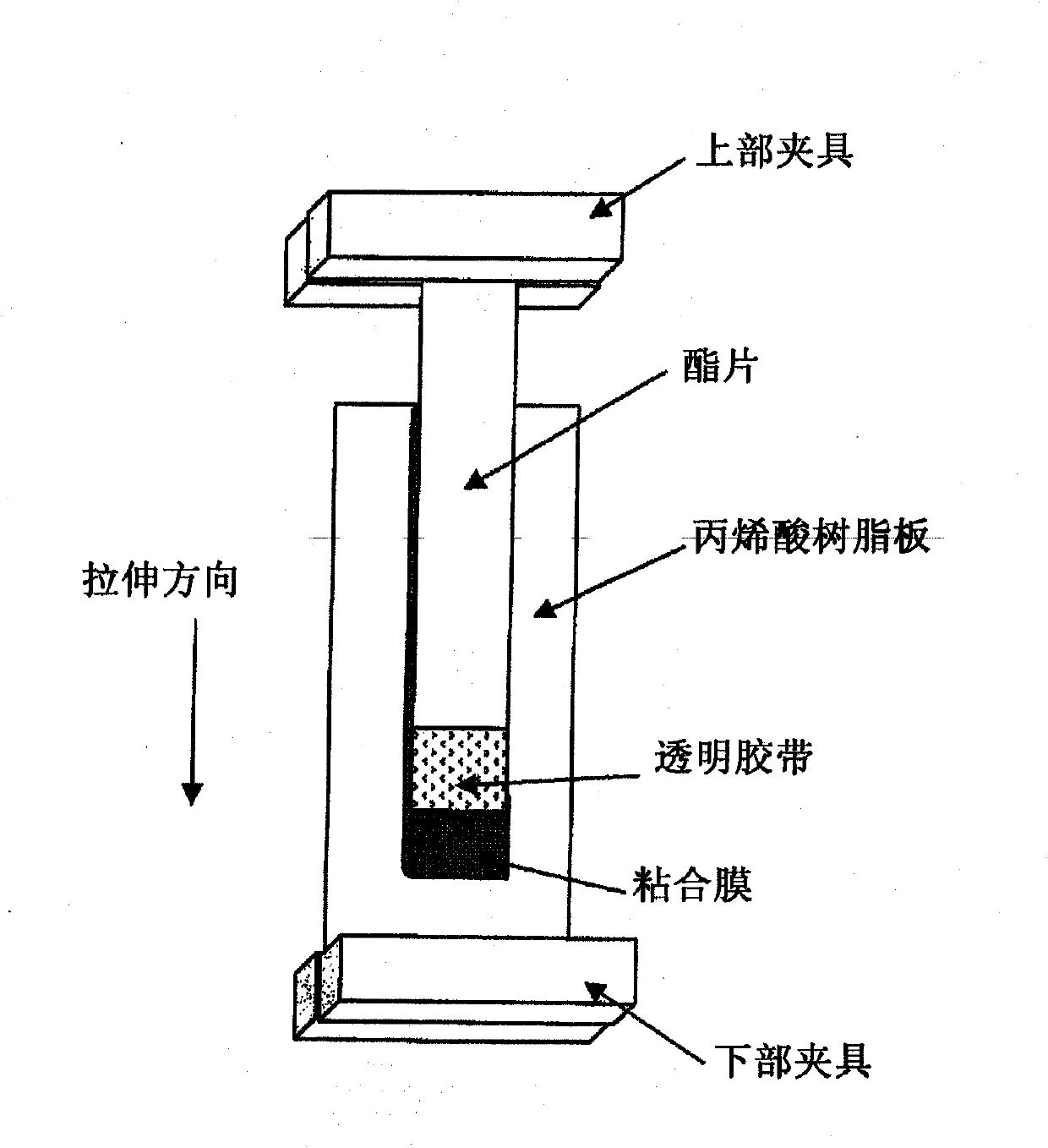

Method used

Image

Examples

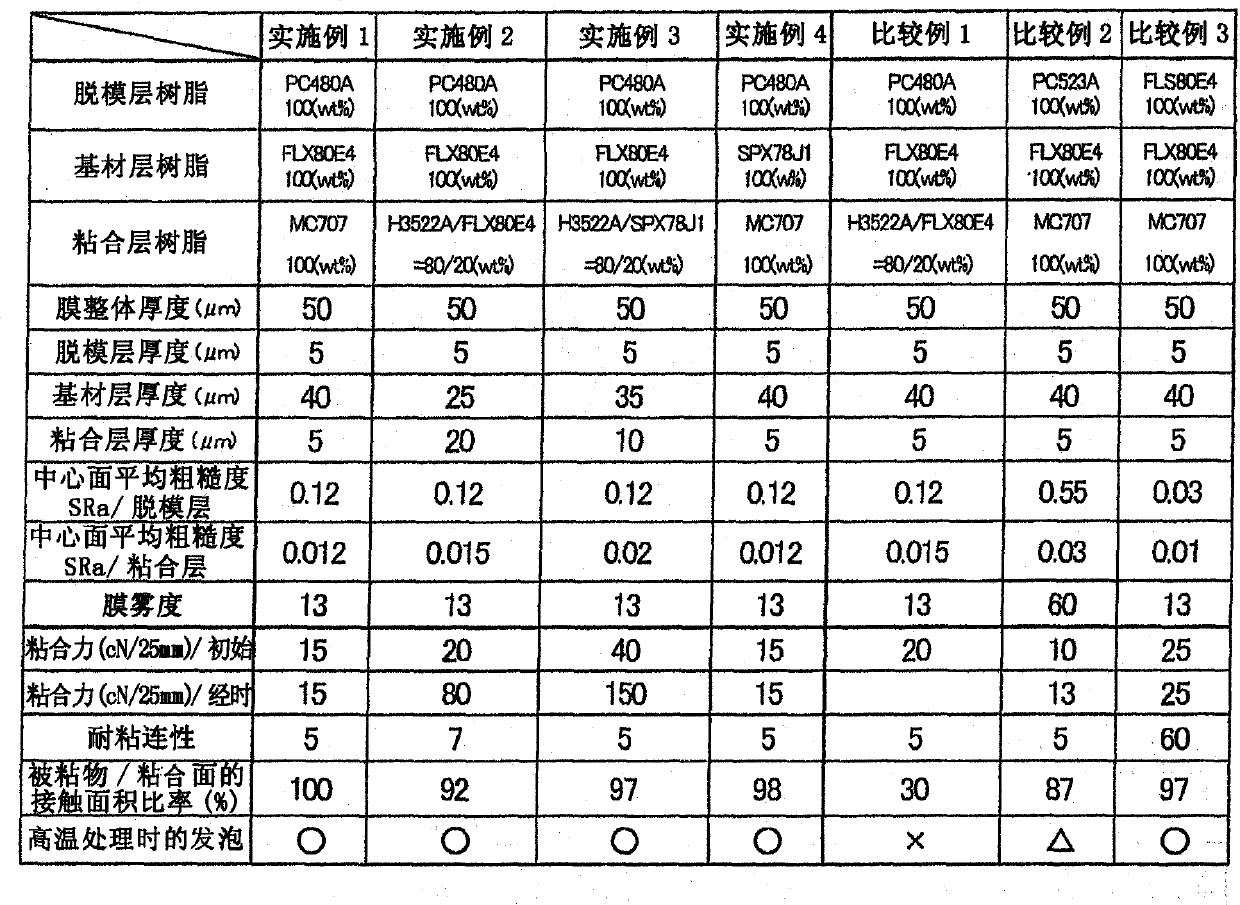

Embodiment 1

[0122] (Production of base material layer)

[0123] use A uniaxial extruder (L / D: 22.4) melt-extruded a homopolypropylene resin (manufactured by Sumitomo Chemical Co., Ltd.: FLX80E4, tensile modulus of elasticity: 1500 MPa) 100 wt% to form a substrate layer.

[0124] (Production of adhesive layer)

[0125] use A biaxial extruder (L / D: 19) melted and extruded 100 wt% of an olefin-based elastomer (Mitsubishi Chemical Corporation: ZEALOUS MC707) as an adhesive layer.

[0126] (Production of release layer)

[0127] use A single-screw extruder (L / D: 25) melt-extruded 100% by weight of a propylene-ethylene block copolymer (manufactured by SunAllomer: PC480A) as a release layer.

[0128] (Making of film)

[0129] Three-layer T-die (multi-manifold type, die lip width 250mm, die lip gap 1mm) at 250°C with the base layer, adhesive layer, and release layer being melted in each extruder. Laminated extrusion is implemented inside. While blowing air to a casting roll with a temperature of 20°C wit...

Embodiment 2

[0132] The base layer and the release layer were the same as in Example 1, and the adhesion layer and the ratio of each layer were changed to the following contents, and three types of three-layer unstretched films were obtained by the same manufacturing method as in Example 1.

[0133] (Adhesive layer)

[0134] Amorphous PP (manufactured by Sumitomo Chemical: Tafthren H3522A, heat of crystallization and crystallization: 28J / g) and homopolypropylene resin (manufactured by Sumitomo Chemical: FLX80E4, tensile modulus of elasticity: 1500 MPa) Mix at a ratio of 20% by weight, and use the mixture A twin-screw extruder (L / D: 19) was melt-extruded as an adhesive layer.

[0135] (Making of film)

[0136] Three-layer T-die (multi-manifold type, die lip width 250mm, die lip gap 1mm) at 250°C with the base layer, adhesive layer, and release layer being melted in each extruder. Laminated extrusion is implemented inside. While blowing air to a casting roll with a temperature of 20°C with a blow...

Embodiment 3

[0139] The base layer and the release layer were the same as in Example 1, and the layer ratio of the adhesive layer and each layer was changed to the following content, and three types of three-layer unstretched films were obtained by the same manufacturing method as in Example 1.

[0140] (Adhesive layer)

[0141] Amorphous PP (manufactured by Sumitomo Chemical: Tafthren H3522A, heat of crystallization and crystallization: 28J / g) and propylene-1-butene copolymer (manufactured by Sumitomo Chemical: SPX78J1, tensile modulus: 530MPa) Mix in the ratio of 80 / 20wt%, use A biaxial extruder (L / D: 19) melted and extruded the mixture as an adhesive layer.

[0142] (Making of film)

[0143] Three-layer T-die (multi-manifold type, die lip width 250mm, die lip gap 1mm) at 250°C with the base layer, adhesive layer, and release layer being melted in each extruder. Laminated extrusion is implemented inside. While blowing air to the casting roll with a temperature of 20°C with a blower, the extru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com