LED fluorescent lamp

A technology of LED fluorescent lamps and LED light sources, applied in lampshades, light sources, electric light sources, etc., can solve the problems of poor heat dissipation, high local temperature, hot hands, etc., to achieve good heat dissipation, enhance stability, and reduce temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

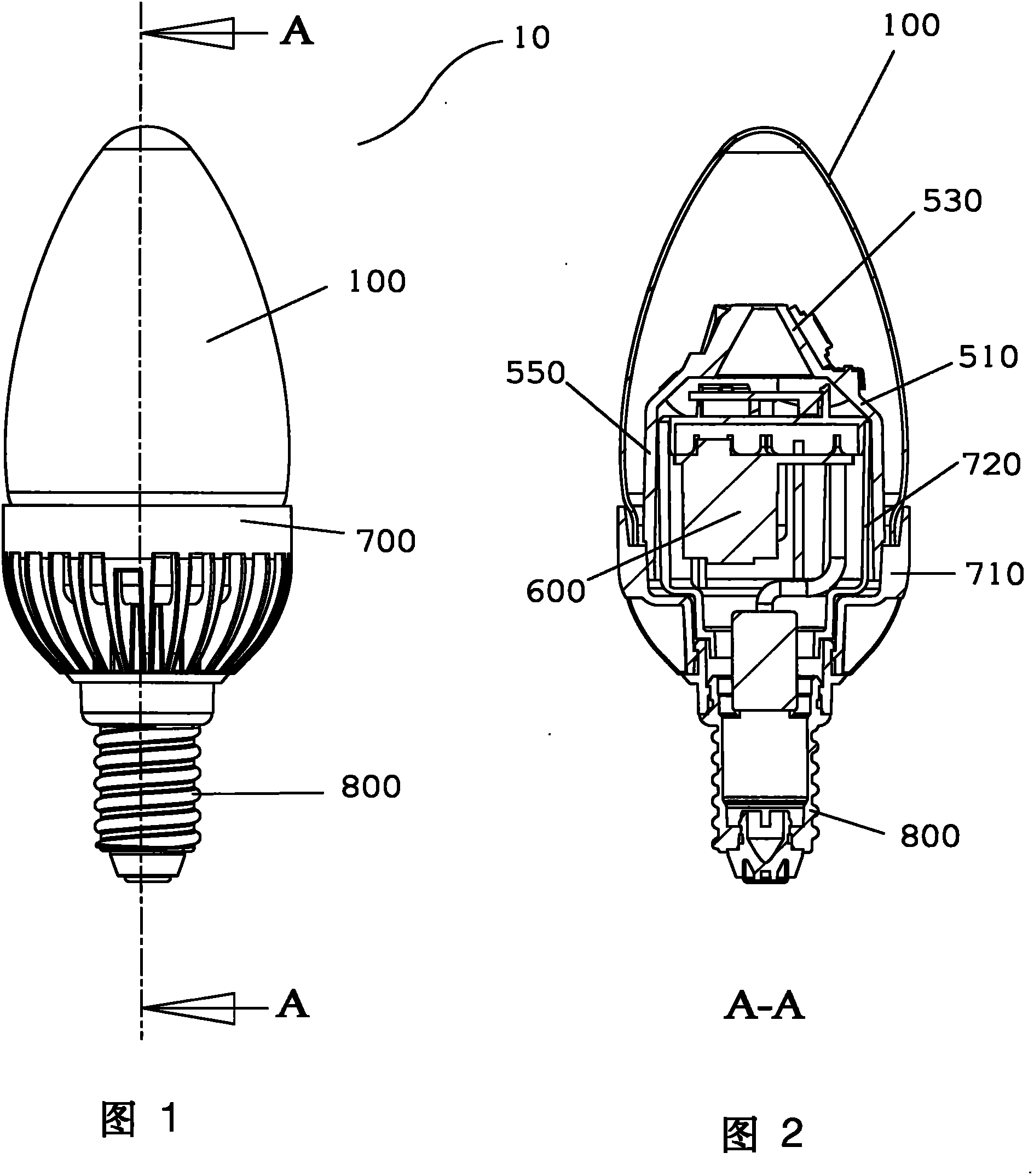

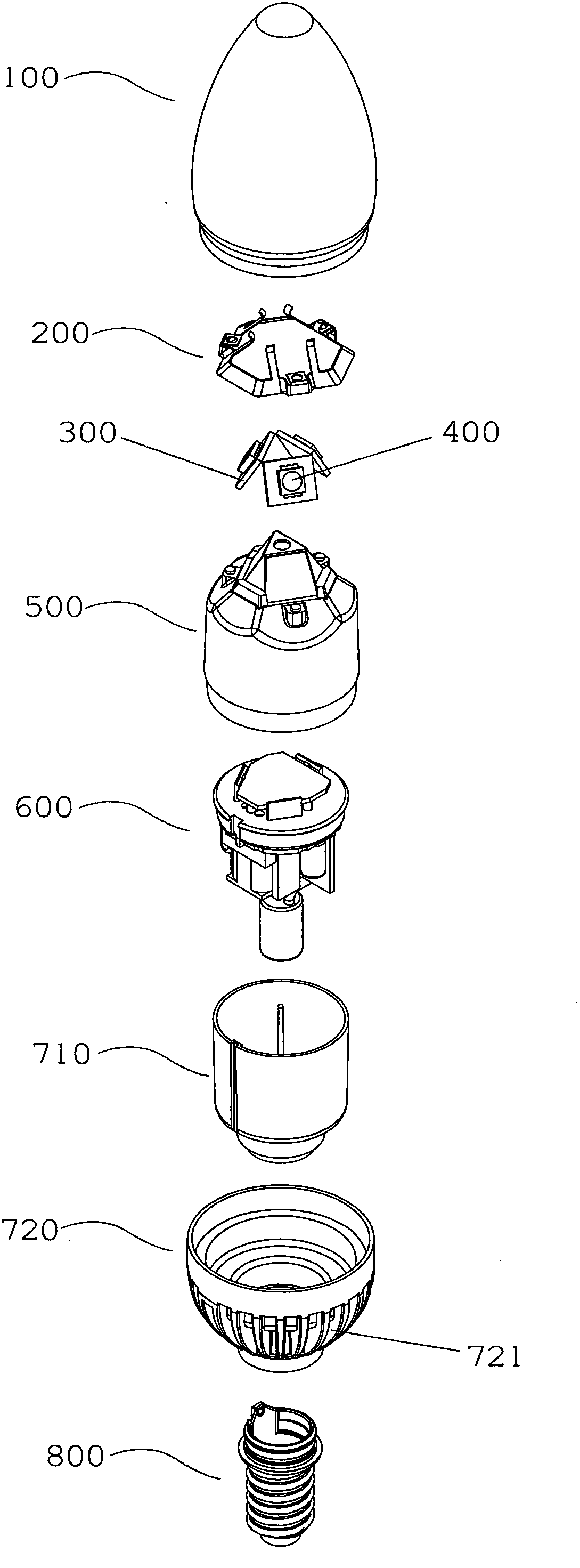

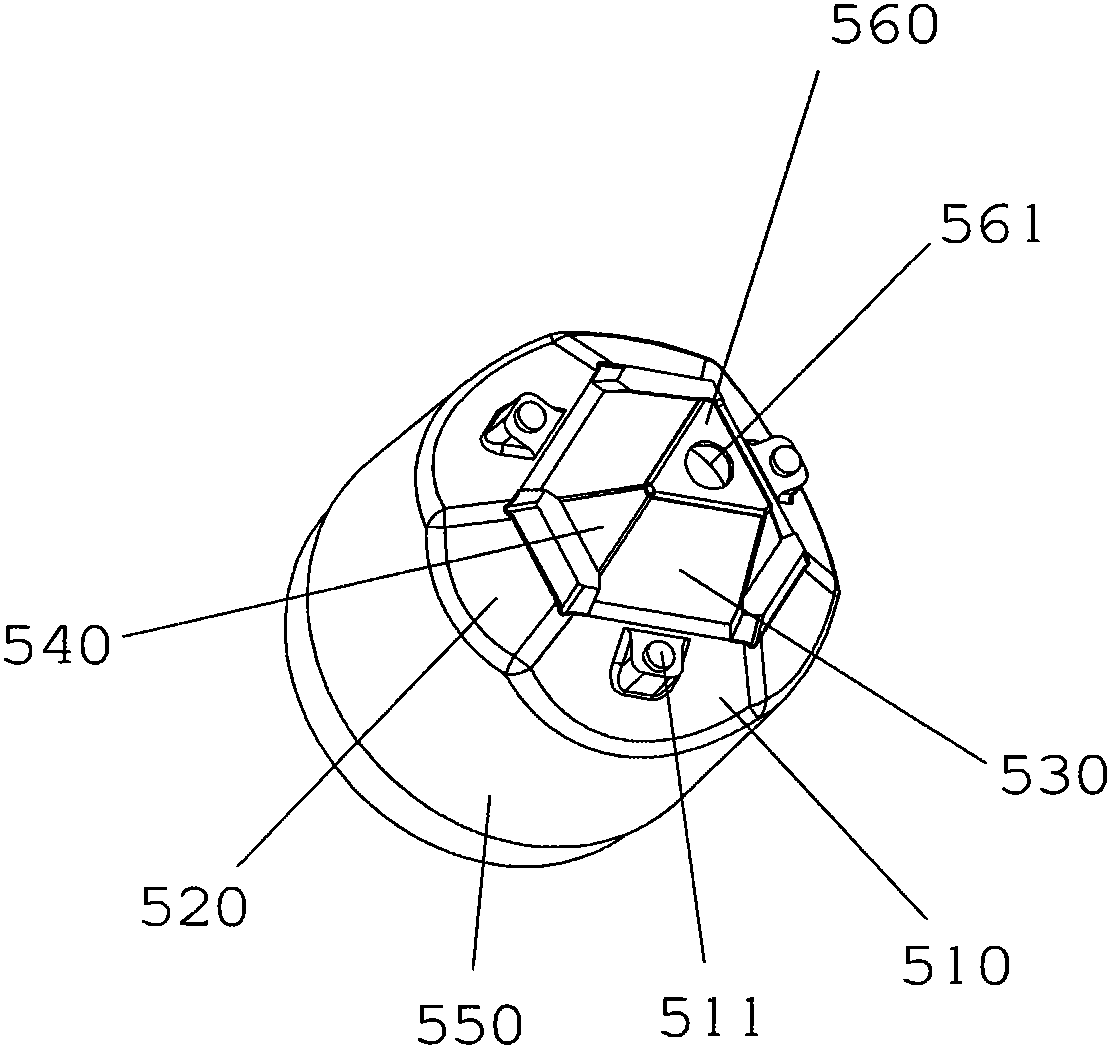

[0031] refer to Figure 1 to Figure 3 , the figure shows an LED fluorescent lamp 10 as a preferred embodiment of the present invention, the fluorescent lamp 10 includes a glass bulb 100, three LED light sources 400, three light source panels 300, a heat conducting device 500, a control circuit 600, and a rear cover 700 And the lamp head 800.

[0032] The glass bubble 100 can be a transparent glass bubble, or a glass bubble sprayed with silica gel, a twisted glass bubble, a frosted glass bubble, etc. can be selected as required. The lamp holder 800 can be designed as lamp holders of various sizes as required, such as E11, E12, E14, E17, E26, E27 and so on. The control circuit 600 is not the main point of the present invention, and will not be described in detail here.

[0033] The LED light source can consist of one or more LEDs. In this embodiment, each of the three LED light sources 400 is composed of three chip LEDs, which are respectively fixed on three light source pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com