Liquid dairy product containing cheese particles and manufacturing method of liquid dairy product

A production method and technology of dairy products, applied in the direction of dairy products, milk preparations, cheese substitutes, etc., can solve the problems of unseen products on the market, unseen technical reports of cheese and liquid dairy products, etc., and achieve strong cheese flavor and taste Lubricating and delicate, excellent stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

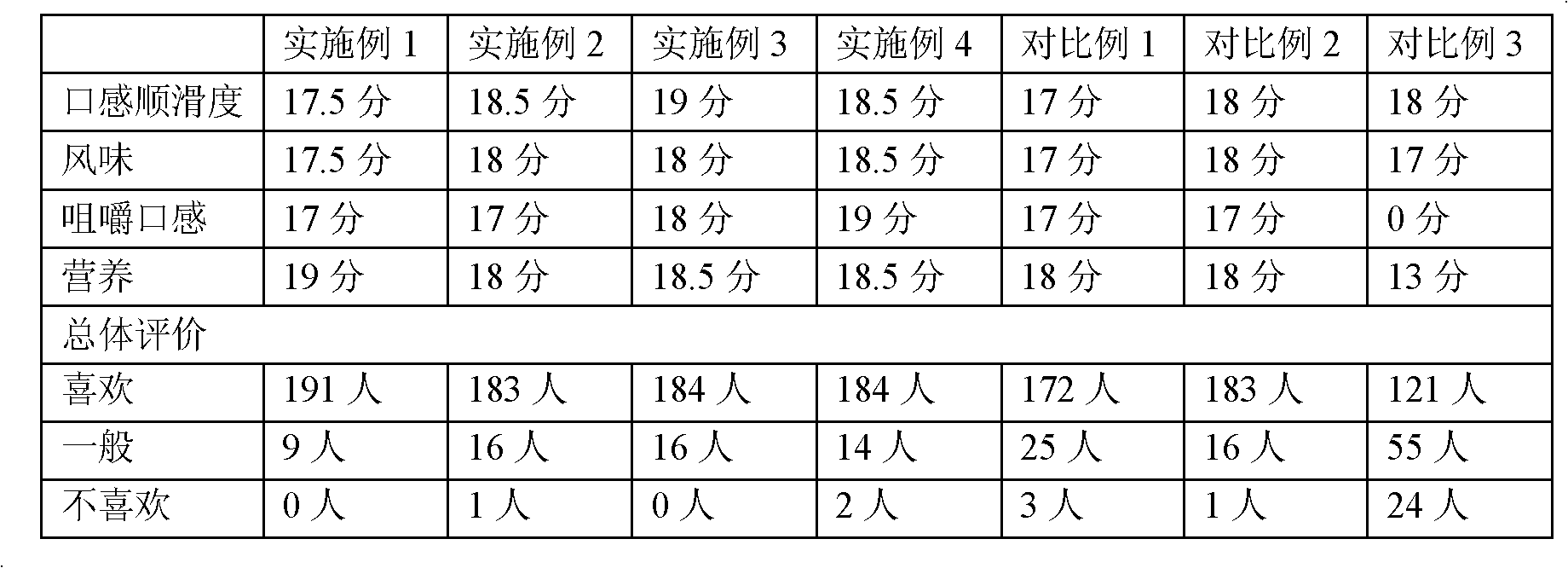

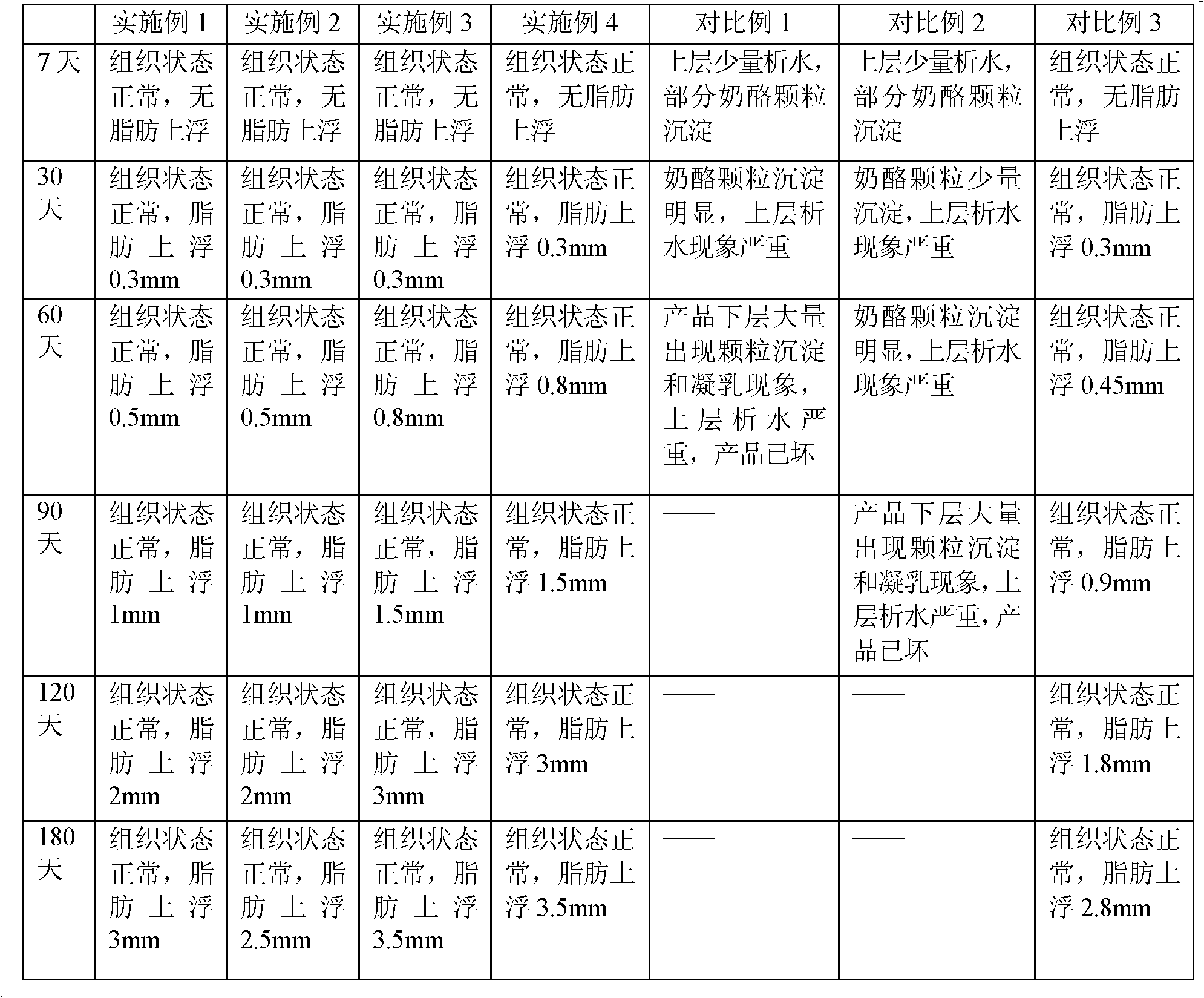

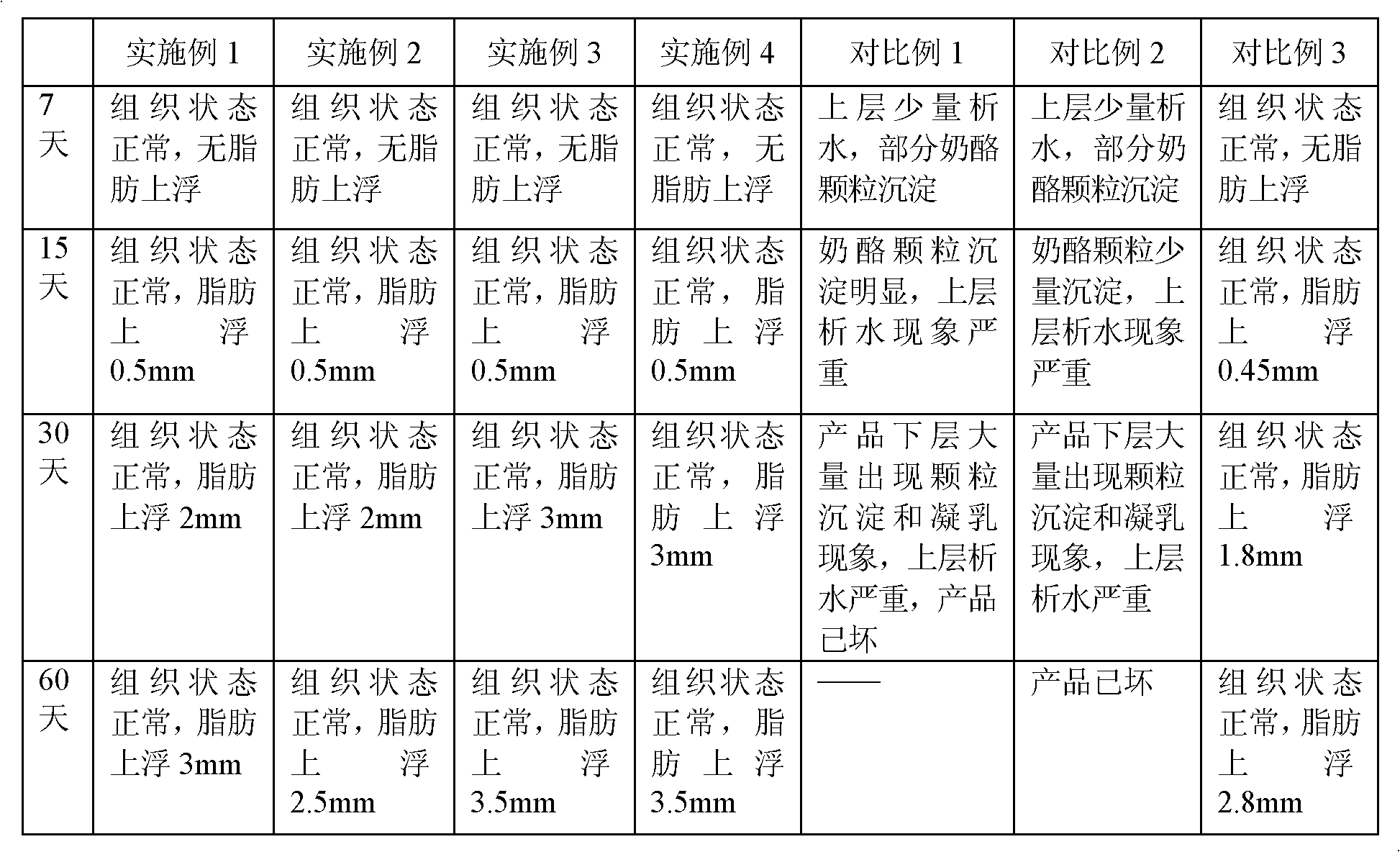

Examples

Embodiment 1

[0041] Embodiment 1, seasoned milk containing cheese granules and production method thereof

[0042] 1. Formula of flavored milk containing cheese granules (based on one ton of product):

[0043] Milk 800kg

[0044] 100kg cheese granules

[0045] Carrageenan 0.15 kg

[0046] Microcrystalline cellulose 3.0 kg

[0047] Guar gum 0.1 kg

[0048] Sodium alginate 0.4 kg

[0049] Glyceryl monostearate 0.3 kg

[0050] Sucrose esters 0.8 kg

[0051] 40kg white sugar

[0052] Food flavor 1.1 kg

[0053] water balance

[0054] Raw material standard:

[0055] Cheese particles are spherical particles with a diameter of 5 mm.

[0056] Milk: protein ≥ 2.95%, fat ≥ 3.0%, non-fat milk solids ≥ 8.5%.

[0057] All raw materials meet the requirements of corresponding quality standards.

[0058] 2. Production method of seasoned milk containing cheese granules

[0059] The production method of the flavored milk containing cheese granules of the present embodiment mainly comprises the ...

Embodiment 2

[0065] Embodiment 2, seasoned milk containing cheese granules and production method thereof

[0066] Prepare the flavored milk of the present embodiment according to the following formula (in terms of one ton of product):

[0067] Milk 900kg

[0068] White sugar 28kg

[0069] Carrageenan 0.1 kg

[0070] Microcrystalline cellulose 2.0 kg

[0071] Sodium alginate 0.2 kg

[0072] Glyceryl monostearate 0.5 kg

[0073] Sodium stearoyl lactylate 0.12 kg

[0074] Food flavor 1.1 kg

[0075] 10 kg cheese granules

[0076] water balance

[0077] Raw material standard: Cheese particles are basically spherical particles with a particle diameter of about 1mm. The production method is as follows:

[0078] According to the ratio of commercially available cheese powder (about 1% whey protein content) 45%, high fructose syrup 42%, pectin 0.8‰, gellan gum 0.6‰, sodium alginate 0.2‰, and the balance of water, the chemical ingredients Pour an appropriate amount of water into the tank, ...

Embodiment 3

[0081] Embodiment 3, milk drink containing cheese particles and production method thereof

[0082] Prepare milk drink of the present invention (in terms of one ton of product) according to the following formula:

[0083] Milk 400kg

[0084] White sugar 56 kg

[0085] Sodium carboxymethyl cellulose 0.5 kg

[0086] Microcrystalline cellulose 2.0 kg

[0087] Sucrose esters 0.8 kg

[0088] Modified starch 2.5 kg

[0089] Glyceryl monostearate 0.3 kg

[0090] Xanthan gum 0.1 kg

[0091] Maltodextrin 0.5 kg

[0092] Food flavor 1.1 kg

[0093] 60 kg cheese granules

[0094] water balance

[0095] Raw material standard: Cheese particles are spherical particles with a particle size close to 3mm. The production method is as follows:

[0096] According to the ratio of commercially available cheese powder (about 1.5% whey protein content) 40%, high fructose syrup 48%, pectin 0.6‰, gellan gum 0.5‰, sodium alginate 0.4‰, and the balance of water, the ingredients Pour an appropr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com