Pearl cheese as well as preparation method and food thereof

A technology of cheese and pearls, which is applied in the direction of milk preparations, dairy products, baked goods, etc., can solve the problems of lack of freshness and weak bursting feeling, and achieve the effect of enriching nutritional value, increasing interest, and improving nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

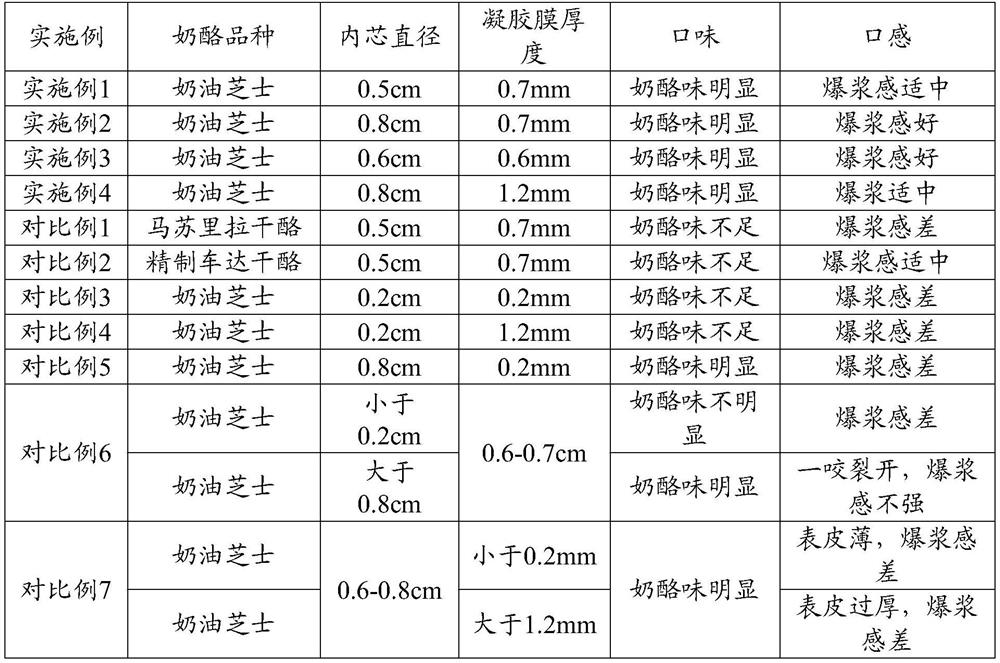

Examples

Embodiment 1

[0033] Add 1.0% sodium alginate and 1.0% carrageenan to water at 60°C, dissolve and cool. The cream cheese was prepared into spheres with a diameter of 0.5 cm, and the cheese granules were soaked in a 15% calcium gluconate solution for 4 minutes; the soaked cheese spheres were filtered through a mesh and immersed in a flow tank of a mixed solution of sodium alginate and carrageenan , for 8min, that is, a gel film of 0.7mm is formed on the cheese surface; filter out the cheese balls coated with gel on the surface with a sieve, and rinse with running water for 15-30 seconds;

[0034] The product obtained in this example was soaked in water at 65° C. for 1 min, and the cheese taste was obvious and the popping feeling was moderate.

Embodiment 2

[0036] Add 1.5% sodium alginate and 1.0% carrageenan to water at 60°C, dissolve and cool. The cream cheese was prepared into spheres with a diameter of 0.8 cm, and the cheese granules were soaked in a 15% calcium gluconate solution for 5 min; the soaked cheese spheres were filtered through a mesh and immersed in a flow tank of a mixed solution of sodium alginate and carrageenan , for 8min, that is, a gel film of 0.7mm is formed on the cheese surface; filter out the cheese balls coated with gel on the surface with a sieve, and rinse with running water for 15-30 seconds;

[0037] The product obtained in this example was soaked in water at 65° C. for 1 min, and the cheese taste was obvious and the popping feeling was good.

Embodiment 3

[0039] Add 1.5% sodium alginate and 1.0% carrageenan to water at 60°C, dissolve and cool. The cream cheese was prepared into spheres with a diameter of 0.6 cm, and the cheese granules were soaked in a 15% calcium gluconate solution for 4 minutes; the soaked cheese spheres were filtered through a mesh and immersed in a flow tank of a mixed solution of sodium alginate and carrageenan , keep for 6min, that is, a 0.6mm gel film is formed on the cheese surface; filter out the cheese balls coated with gel on the surface with a sieve, rinse with running water for 15-30 seconds;

[0040] The product obtained in this example was soaked in water at 65° C. for 1 min, and the cheese taste was obvious and the popping feeling was good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com