Patents

Literature

325 results about "Glucobiogen" patented technology

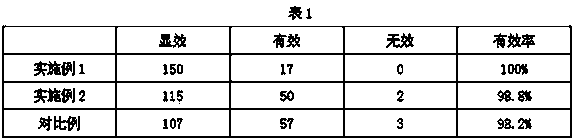

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Seacucumber-blueberry instant particles and processing method thereof

ActiveCN101897458ARich in nutrientsSignificant nourishing and health effectsFood preparationNutrientNutritional composition

The invention relates to seacucumber-blueberry instant particles and a processing method thereof. Seacucumber, blueberry and barbary wolfberry fruit are taken as major raw materials, vitamin C, citric acid, xylitol, a sweetener and an excipient are taken as auxiliary raw materials and nutrient components such as zinc gluconate, taurine, vitamin E acetate, collagen, L-carnitine, calcium gluconate and the like are added as required by different people. The method comprises the following steps of: performing pretreatment, biological enzymolysis, extraction and drying on the raw materials; extracting active components in the raw materials; and mixing, pelletizing, drying and disinfecting the active components to obtain the instant particles. Protein in the seacucumber is hydrolyzed to exist in the form of small molecule peptides so that the protein is easy to be absorbed by human bodies, the activities of nutrient substances in a mixture are kept, the active components are stabilized in a product, the original juice, original taste and original colors of the raw materials are kept and the medicinal value, nutrient value and drinking value of the mixture of a plurality of raw materials are enhanced. The particles have the advantages of bright color, uniform form, stable property, rich nutrition, pleasant sweetness and sourness, convenient drinking and remarkable nourishing effect.

Owner:辽宁阿里郎生物工程股份有限公司

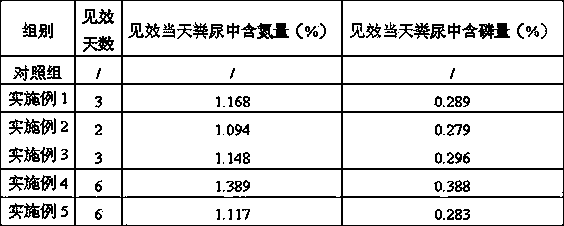

Pig feed complex enzyme preparation and preparing method thereof

ActiveCN104000051AFast growthGood for healthAnimal feeding stuffAccessory food factorsBiotechnologyFeed conversion ratio

Owner:河源双胞胎饲料有限公司

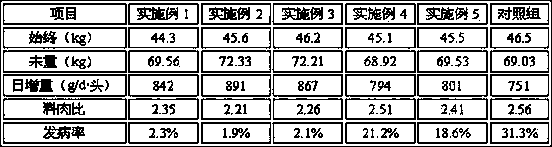

Nutrient composition for enhancing shell hardening speed of shrimp and crab, preparation method and application thereof

InactiveCN101756026AImprove the immunityEffective digestion and absorptionAnimal feeding stuffCalcium in biologyAnti stress

The invention discloses a nutrient composition for enhancing shell hardening speed of shrimp and crab. The composition comprises the following components in percentage by weight: 1-50% of calcium gluconate, 1-40% of shell factor, 1-40% of immunity enhancement factor and 1-40% of traditional Chinese medicine anti-stress factor. The nutrient composition contains a plurality of active ingredients indispensable for aquatic animal growth, effectively enhances calcium, increases shell hardening speed, effectively improves the immunity of the shrimp and crab organisms, supplements indispensable mineral matters and microelements in a shrimp and crab culturing water body, accelerates the shell hardening of the shrimp and crab, prevents the failure of the shrimp and crab shelling and has the advantages of no toxic or side effect or medicament residue, convenient use and low cost.

Owner:TIANJIN REBATE SCI & TECH DEV

Lead-removing health care food and preparation method thereof

InactiveCN1465285AWith adsorption and detoxificationReduce absorptionOrganic active ingredientsAntinoxious agentsVitamin CMedicine

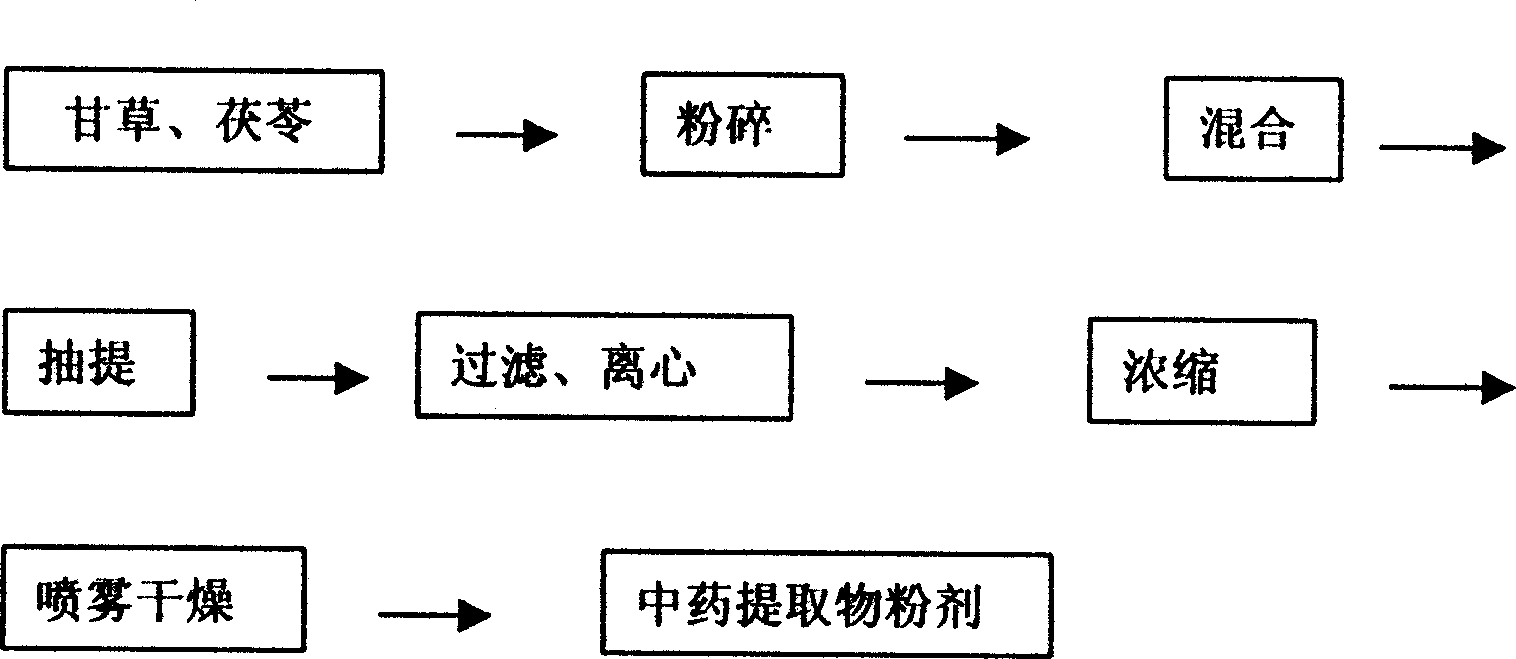

The present invention discloses a health-care food with the function of discharging lead from human body and its preparation method. It is made of chitosan, chitooligose, locirce and poria extract asmain effective component, and using sodium alginate, pectin, vitamin C, zinc gluconate and calcium gluconate as auxiliary material and combining them to obtain the invented product.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

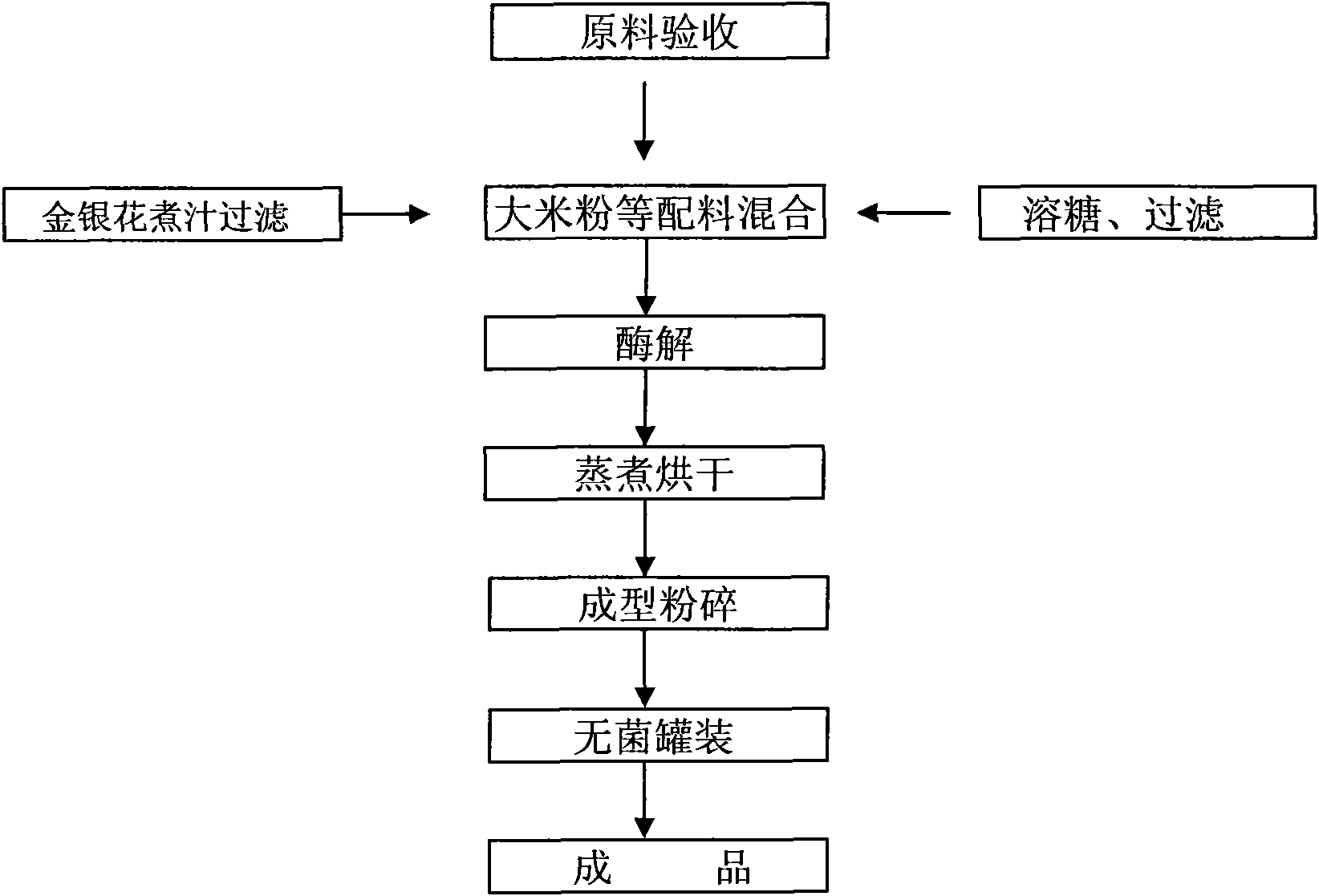

Honeysuckle nourishing rice flour for babies and method of preparing the same

The present invention belong to baby food, health products technical field, relating to a honeysuckle nourishing rice flour for babies and method of preparing the same. The honeysuckle baby nourishing rice flour of the invention includes raw stuff components as follows: rice flour, sucrose, milk powder, cream, honeysuckle, calcium hydrogen orthophosphate, sodium chloride, calcium gluconate, ferrous gluconate, gluconic acid, vitamin A, nicotinic acid, vitamin B1, vitamin B2, vitamin D1, potassium iodate, oligofructose, docosahexenoic acid and arachidonic acid. The products prepared via steps of preparing honeysuckle juice, dissolving sugar, batching, enzymolysis, cooking, drying, molding, crushed filling. The preparing technics of the invention is simple and easy, suitable for large scale industrial production, and the obtained honeysuckle baby nourishing rice flour combining the baby nourishing rice flour and active ingredient of honeysuckle scientifically, possessing important meaning for promoting healthy growth of babies.

Owner:广东东泰乳业有限公司

Method for preparing D-arabinose

InactiveCN102351916AReduce manufacturing costSimple stepsSugar derivativesSugar derivatives preparationIron sulfateChromatographic separation

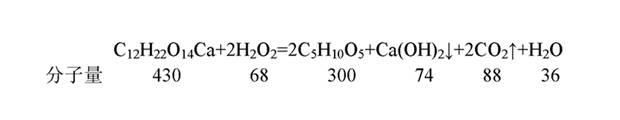

The invention relates to a method for preparing D-arabinose, and belongs to the technical field of functional sugar. In the method, hydrogen peroxide is controllably added to convert calcium gluconate serving as a raw material into the D-arabinose in the presence of iron sulfate serving as a catalyst; D-arabinose liquid obtained through reaction is subjected to subsequent treatment processes of precipitation reaction, filtration, decolorization, ion exchange and chromatographic separation to form D-arabinose liquid with the purity of over 85 percent; and the D-arabinose liquid is subjected to evaporation concentration and natural cooling crystallization to form D-arabinose crystals. The method comprises the following process steps of: (1) preparing the D-arabinose liquid; (2) refining the D-arabinose liquid; and (3) crystallizing to obtain the D-arabinose crystals with the purity of 96 to 99.9 percent. The calcium gluconate is converted into the D-arabinose, and the steps are simple; and relatively cheap iron sulfate is used as the catalyst, so that the production cost of the D-arabinose is reduced, and the yield of the D-arabinose is improved.

Owner:FUTASTE PHARM CO LTD

Pig feed additive for improving intestinal tract health and promoting growth

ActiveCN104304728AEnhance digestionIncrease profitFood processingAnimal feeding stuffBiotechnologyAnimal science

The present invention discloses a pig feed additive for improving intestinal tract health and promoting growth, and belongs to the field of feed additives. The additive comprises fermented Chinese herbal powder, mulberry polysaccharides, paniculate microcos leaf powder, Lithospermum erythrorhizon powder, a microecological preparation, composite vitamin, ferrous lactate, calcium gluconate and carriers, wherein the carriers are bran and peanut shells. According to the additive, with the scientific compounding, the pig intestinal tract health can be effectively improved, the pig diarrhea rate can be reduced, the pig growth can be promoted, the slaughter time can be shortened, the economic benefit and the breeding effect can be increased, and the application prospect is broad.

Owner:JIANGXI TWINS IND

Health food capable of increasing bone density and delaying senility and its production process

InactiveCN1416728AEnsure reliabilityGuarantee stabilityAntinoxious agentsSkeletal disorderIncreased Bone DensityIsoflavones

The health food capable of increasing bone density and delaying senility consists of the effective components of soybean, epimedium, astragalus root, angelica and mulberry as well as supplementary material including calcium gluconate, carboxymethyl starch sodium and avicel. The preparation process of the health food includes supercritical CO2 extraction to obtain angelica oil; ethanol extraction to obtain soybean isoflavone; water extraction of epimedium, astragalus root, mulberry and angelica after extracting oil, spray drying and other steps to prepare powder; mixing soybean isoflavone and the powder as well as calcium gluconate, carboxymethyl starch sodium and avicel; pelletizing, tableting and coating to obtain the health food product.

Owner:SHANGHAI MODERN CHINESE TRADITIONAL MEDICINE TECH DEV

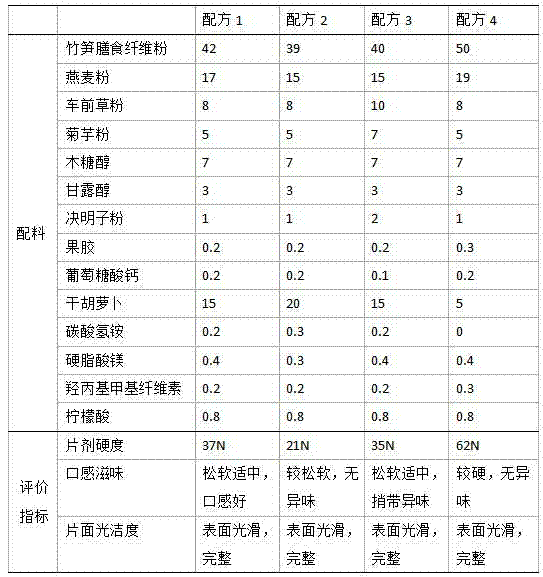

Preparation method for reducing hardness of dietary fiber chewable tablets

The invention discloses a preparation method for reducing hardness of dietary fiber chewable tablets. Dietary fiber chewable tablets are prepared by the procedures of utilizing bamboo shoot dietary fiber powder as main material and carrot, oat, plantain herb, jerusalem artichoke, cassia seed, mannitol, xylitol and calcium gluconate as auxiliary materials, smashing, sieving, mixing, pelleting, drying, tabletting, baking sterilizing, packaging, inspecting and the like. The preparation method is characterized in that on one hand, a gas generating substance (ammonium bicarbonate) is added in the formula, the gas generating substance evaporates in baking sterilizing so that micro gas holes are formed on the chewable tablets, and the chewable tablets become soft and crispy; and on the other hand, large-grained dry carrot added in the formula has low density and certain elasticity, so that the hardness of the chewable tablets is reduced. Dietary fiber chewable tablets prepared according to the preparation method taste smooth, properly soft and sweet and sour, are suitable for middle-aged and elderly people who have bad teeth and need to supplement dietary fibers.

Owner:邯郸市嘉瑞生物科技有限公司

Method for producing industrial grade sodium gluconate or calcium gluconate from yellow ginger starch

InactiveCN102030630AResolve separabilitySolve solubilityCarboxylic acid salt preparationFermentationBiotechnologyPtru catalyst

The invention relates to a method for producing industrial grade sodium gluconate or calcium gluconate from yellow ginger starch. The method comprises the following steps: (1) pre-treating the yellow ginger starch; (2) liquefying by an enzyme method to obtain starch liquefied liquid; (3) saccharifying by the enzyme method to obtain starch saccharified liquid; (4) removing impurities from the starch saccharified liquid and decolorizing to obtain a colorless saccharified liquid; (5) adding a Pd / C catalyst to the saccharified liquid to catalytically oxidize the glucose in the saccharified liquid to prepare sodium gluconate or calcium gluconate; (6) vacuum filtering and recovering the catalyst; and (7) decolorizing the filtrate, concentrating by vacuum evaporation, and crystallizing or spray drying to obtain the finished product of the sodium gluconate or the calcium gluconate. The conversion rate of the yellow ginger starch and the yield of the sodium gluconate or the calcium gluconate are high, the purity is higher than 90%, and the sodium gluconate or the calcium gluconate has high quality and lower production cost, and is especially suitable to be used as a cement enhancer.

Owner:HUBEI DANAO PHARMA CO LTD +1

Method for preparing calcium chitosan and itsuse for wound hemostasis

InactiveCN1814625ABacteriostaticAntibacterialOrganic active ingredientsBlood disorderCITRATE ESTERRed blood cell

This invention relates to a preparation method for calcium chitin characterizing in mixing the chitin with powder of CaCl2, calcium acetate, calcium gluconate, calcium lactate, calcium maltate or citrate calcium malate to be reacted, filtered, cleaned, dewatered, dried, crushed and virus eliminated to get the calcium chitin, which is a new type of hemostatic by acting on the red blood cells in the blood, suppressing soluble fiber protein and activating thrombin so as to arrest bleeding.

Owner:刘万顺

Jelly capable of maintaining beauty and keeping young and preparation method thereof

ActiveCN103976203AUnique formulaGreat tasteNatural extract food ingredientsUltra high pressure food processesBiotechnologyPagoda tree

The invention discloses jelly capable of maintaining beauty and keeping young and a preparation method thereof. The jelly is prepared from the raw materials in parts by weight: 100 parts of bone collagen, 10-15 parts of hyaluronic acid, 15-20 parts of royal jelly, 20-25 parts of glucosamine, 15-20 parts of lentinula edodes, 5-10 parts of hericium erinaceus, 5-10 parts of Kwa root, 15-20 parts of chestnut inside peel, 10-15 parts of tuckahoe, 5-10 parts of sesame, 20-25 parts of strawberry, 15-20 parts of celery, 1-5 parts of pagoda tree flower, 5-10 parts of red yeast, 10-15 parts of maize, 5-10 parts of wheat bran, 5-10 parts of red bean, 10-15 parts of seaweed, 1-5 parts of fishbone, 1-5 parts of fishskin, 1-5 parts of fishscale, 1-5 parts of calcium gluconate and 0.1-0.3 part of zinc gluconate. According to the jelly and the preparation method thereof, the formula is unique, and the collagen is prepared into a jelly shape, so that the oral taking and carrying are more convenient; through the synergism of all the ingredients, the jelly has very good effects on maintaining beauty and keeping young and caring health.

Owner:SHANDONG HAIYU BIOLOGICAL CO LTD

Sea cucumber oral liquid and preparation process thereof

The invention relates to a sea cucumber oral liquid and a preparation process thereof. The sea cucumber oral liquid comprises, 500-1000 parts of sea cucumber, 50-100 parts of kirilow rhodiola root and rhizome, 50-80 parts of mulberry leaf, 50-80 parts of medlar, 50-80 parts of hawthorn, 50-80 parts of common jujube, 10-20 parts of lohanguo siraitia fruit, 50-80 parts of calcium gluconate, and 50-80 parts of vitamin C. The preparation process comprises 11 steps of raw material purification, vacuum freeze drying, coarse crushing, ultrafine crushing, microwave-assisted enzymolysis, enzyme inactivation, filtration, desalination, accessory seasoning liquid processing, material preparing, and filling sterilization. The obtained sea cucumber oral liquid has characteristics of reasonable formulation and fragrant taste, and has effects of exact blood fat lowering, blood sugar lowering and blood pressure lowering, wherein the blood fat lowering effect is especially prominent.

Owner:山东鲁参坊股份有限公司

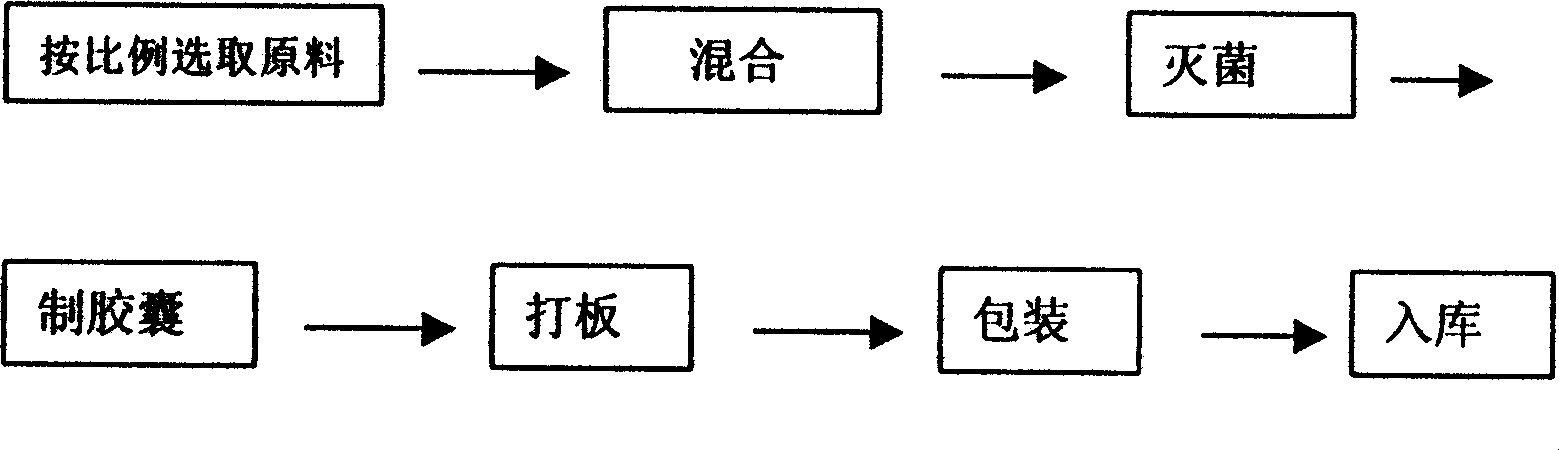

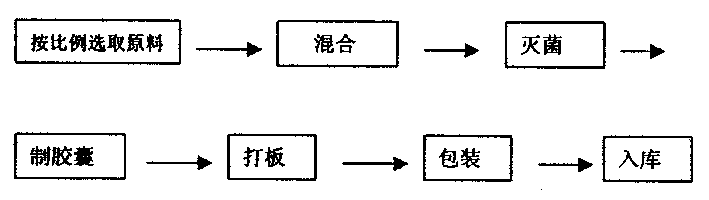

Trepang capsule and preparation process thereof

The invention relates to a trepang capsule and a preparation process thereof. The trepang capsule is composed of 500-1000 parts of trepang, 50-100 parts of gingko, 50-80 parts of acanthopanax leaf, 50-80 parts of folium cortex eucommiae; 50-80 parts of hawthorn, 50-80 parts of Chinese date, 50-80 parts of Chinese wolfberry, 10-20 parts of fructus momordicae, 50-80 parts of calcium gluconate, and 50-80 parts of vitamin C. The preparation process comprises the following eleven steps: raw material purification, vacuum freeze drying, coarse cracking, superfine grinding, microwave auxiliary enzymolysis, enzyme deactivation, filtration, desalting, auxiliary seasoning processing, material proportioning and pelletization, as well as sterilization and packing. The obtained trepang capsule is reasonable in formulation composition and stable in property, has blood sugar decreasing and blood pressure reducing efficacy, and is especially prominent in blood fat reducing efficacy.

Owner:QINGDAO JIARILONG SEAFOOD

Crushed gel-shaped herb tea beverage and preparation method thereof

The invention provides a crushed gel-shaped herb tea beverage and a preparation method thereof. The herb tea is prepared by the following raw materials in part by weight: 5 to 8 parts of white sugar, 0.1 to 1.5 parts of cool Chinese herb composition, 0.3 to 1 part of climbing fig seed gel, 0.3 to 0.8 part of haw, 0.05 to 0.15 part of potassium citrate, 0.01 to 0.1 part of flavoring essence, 0.02 to 0.06 part of calcium gluconate, and water with surplus quantity. The preparation method of the crushed gel-shaped herb tea beverage comprises the following steps that: extracted liquid of cool Chinese herb composition and haw is firstly prepared, then the extracted liquid, the white sugar, the climbing fig seed gel, the potassium citrate and the calcium gluconate are arranged inside a preparation tank to be heated to melt, then the flavoring essence is added, and the mixture is filtered, sterilized, thermally filled and cooled after the volume is fixed by adding water, then the prepared solution is arranged inside a storage room for at least seven days until the herb tea gel is formed in a crushed gel shape. The herb tea beverage has good taste, no precipitate is formed in the beverage,the spleen and the stomach can be strengthened, and the herb tea beverage is convenient to drink.

Owner:摇八下(浙江)食品有限公司

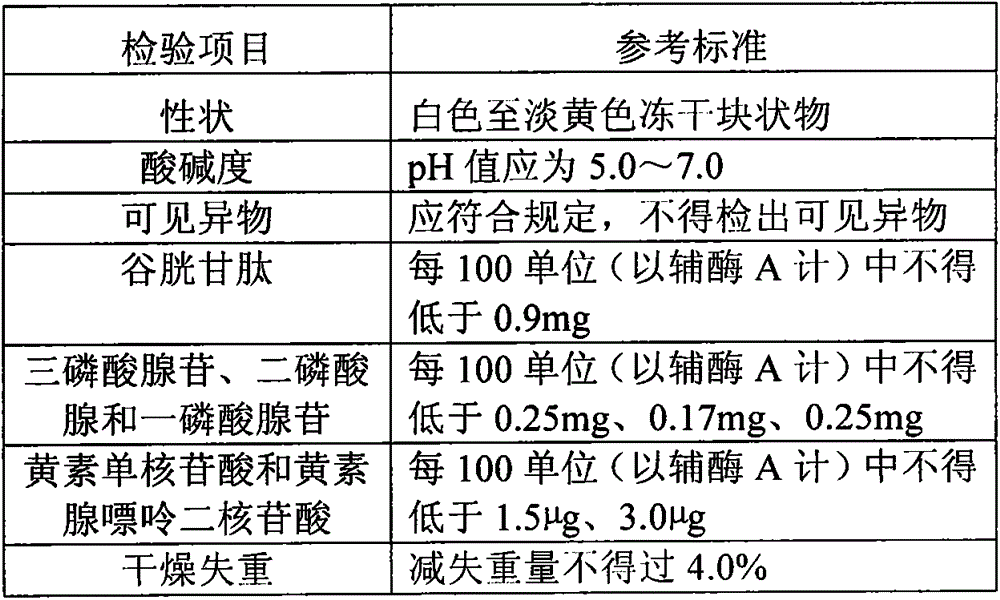

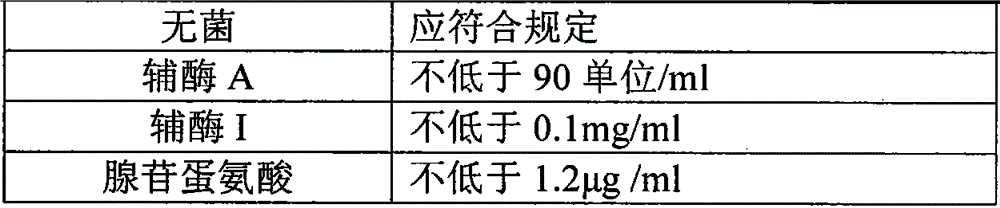

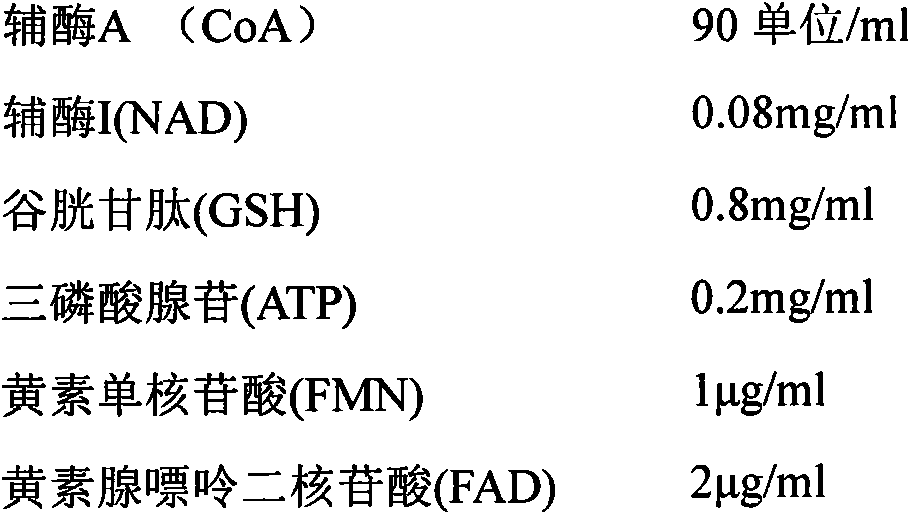

Stable compound coenzyme preparation as well as preparation method and applications thereof

InactiveCN104623626AGood repeatabilityReduce lossOrganic active ingredientsPowder deliveryFlavin adenine dinucleotideDisease

The invention provides a stable compound coenzyme preparation and a preparation method thereof. The main compositions and proportions of the stable compound coenzyme preparation are as follows: 90-120 U of coenzyme A (CoA), 0.1-0.3 mg / ml coenzyme I (NAD), 1-5 mg / ml glutathione (GSH), 1-2.5 mg / ml adenosine triphosphate (ATP), 1.8-12 mu g / ml flavin mononucleotide (FMN), 3-13 mu g / ml flavin adenine dinucleotide (FAD), 0.1-0.4 mg / ml adenosine diphosphate (ADP), 0.2-0.4 mg / ml adenosine monophosphate (AMP), 1.2-15 mu g / ml of adenosine methionine (SAM), 1-5 mg / ml calcium gluconate, 0.5-1.5 mg / ml cysteine hydrochloride, and 0.6-5 mg / ml mannitol. The preparation method overcomes the defects that high-speed centrifugalization is adopted, freeze-drying conditions are not clear and the product stability is poor in the existing method, and the stable compound coenzyme preparation is widely applied to the practices of preparing drugs for treating cardia-cerebrovascular diseases and digestive system diseases.

Owner:BEIJING SL PHARMA +2

Fish gelatin hard capsule and its preparation method

ActiveUS20050069581A1Low methoxylCeramic shaping apparatusPharmaceutical non-active ingredientsAcetic acidHard Capsule

The object of the present invention is to provide a process for preparing fish gelatin capsule comprising the steps of; i) preparing a mixed solution of pectin and glycerin; ii) adding said mixed solution to solubilized fish gelatin solution; iii) adding a small amount of calcium gluconate, sucrose fatty acid esters and glacial acetic acid to said mixture, iv) standing said mixture for adjusting viscosity and v) forming a fish gelatin capsule with obtained fish gelatin mixture, wherein said forming step comprises i) dipping the mold pin into the obtained fish gelatin mixture at the dipping pan, ii) molding the film of the fish gelatin capsule, iii) cooling said film of the fish gelatin capsule using 15˜20° C. cooling air for 5˜10 seconds at the bottom film cooling device, iv) cooling said film of the fish gelatin capsule again using 15˜20° C. cooling air for 100˜120 seconds at the upper film cooling device in order to control the flow of film.

Owner:SUHEUNG CAPSULE CO LTD

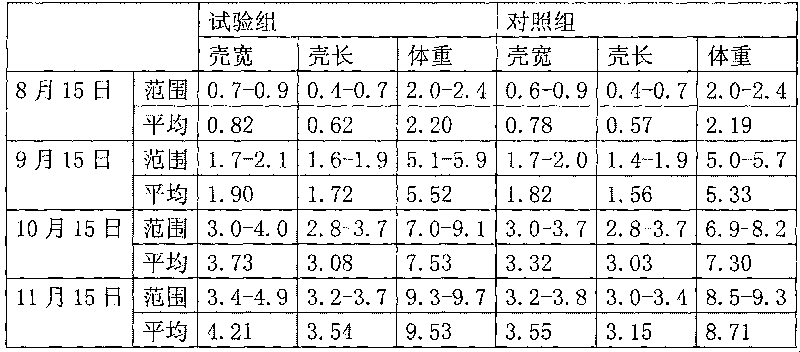

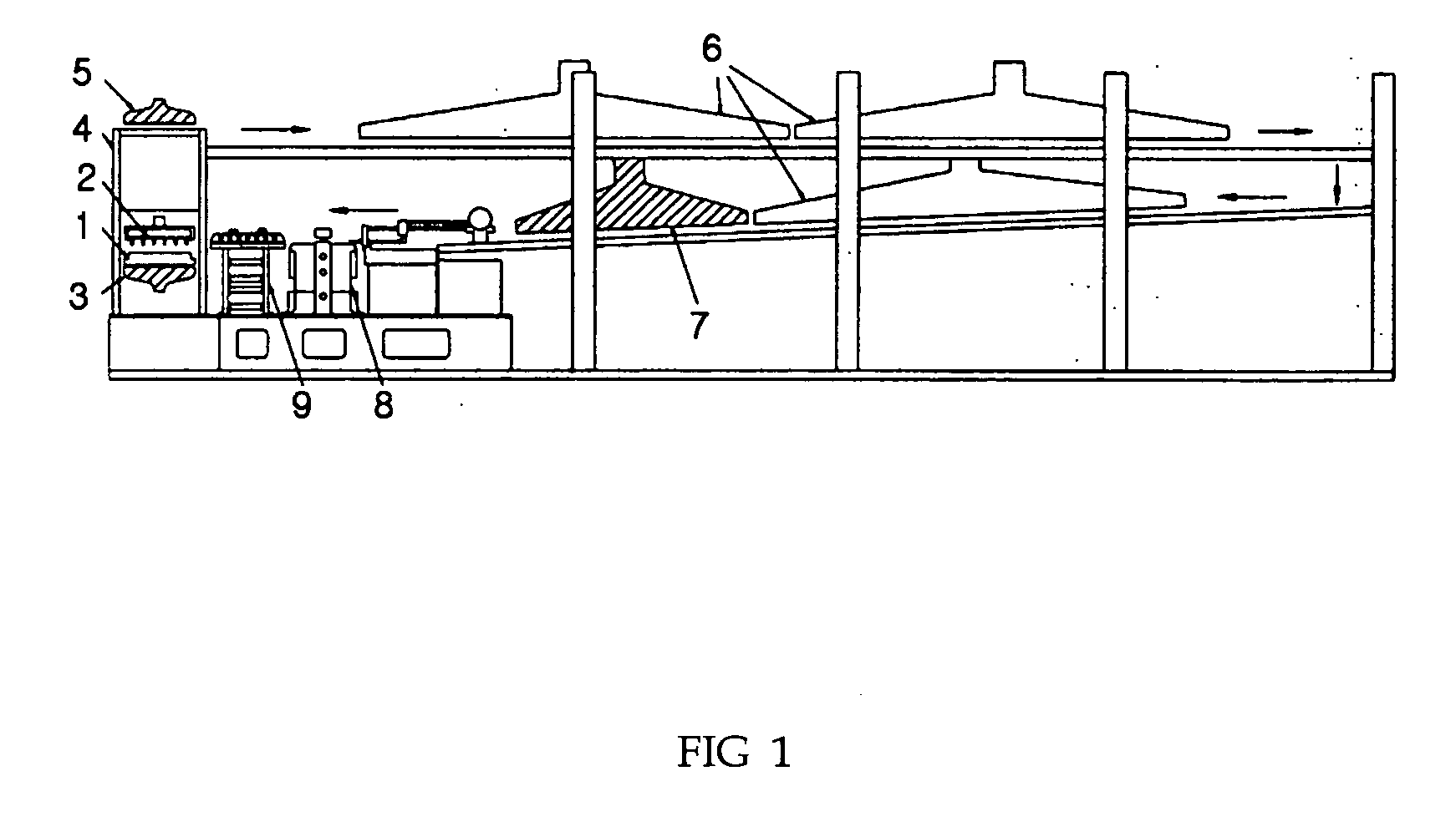

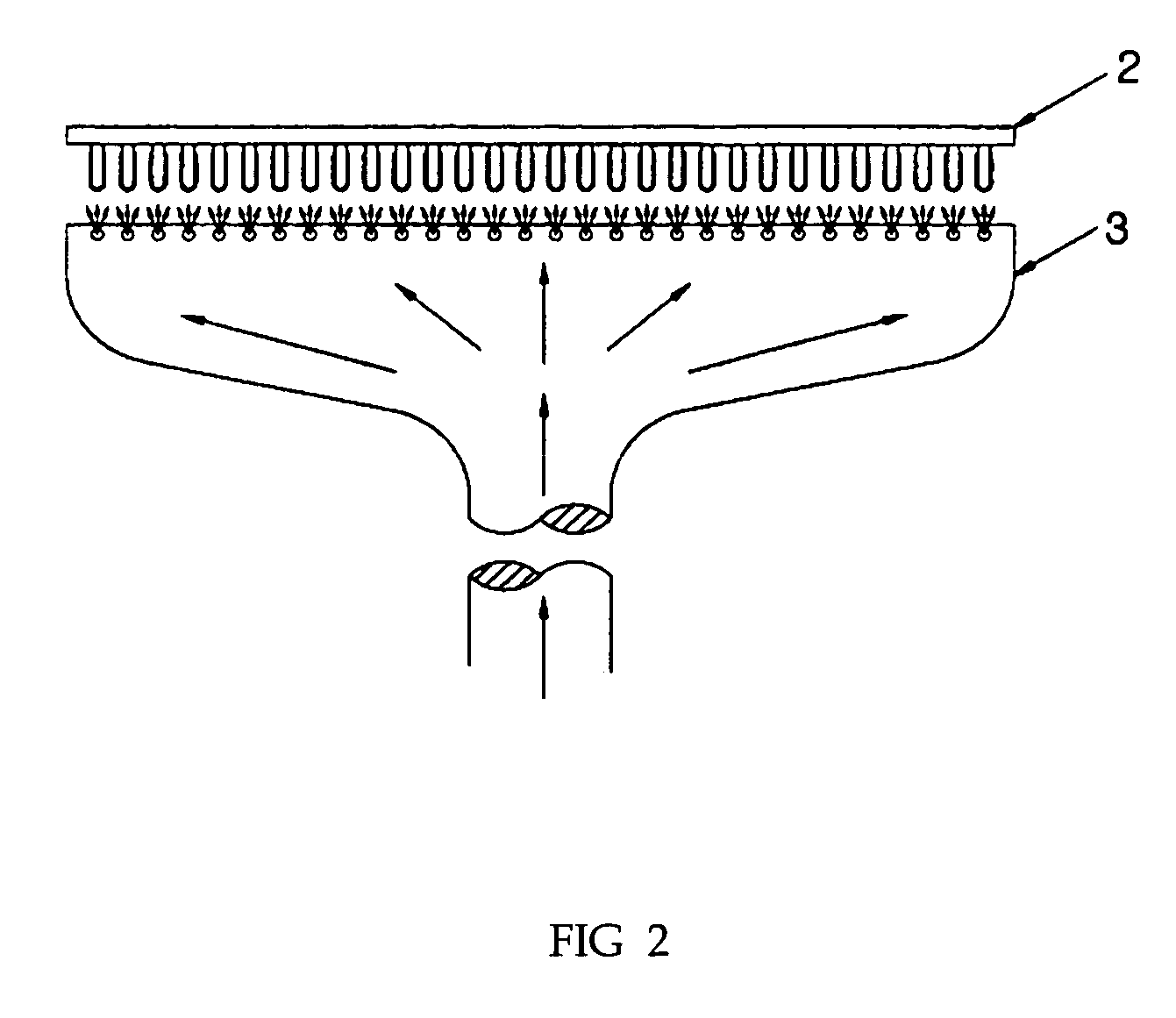

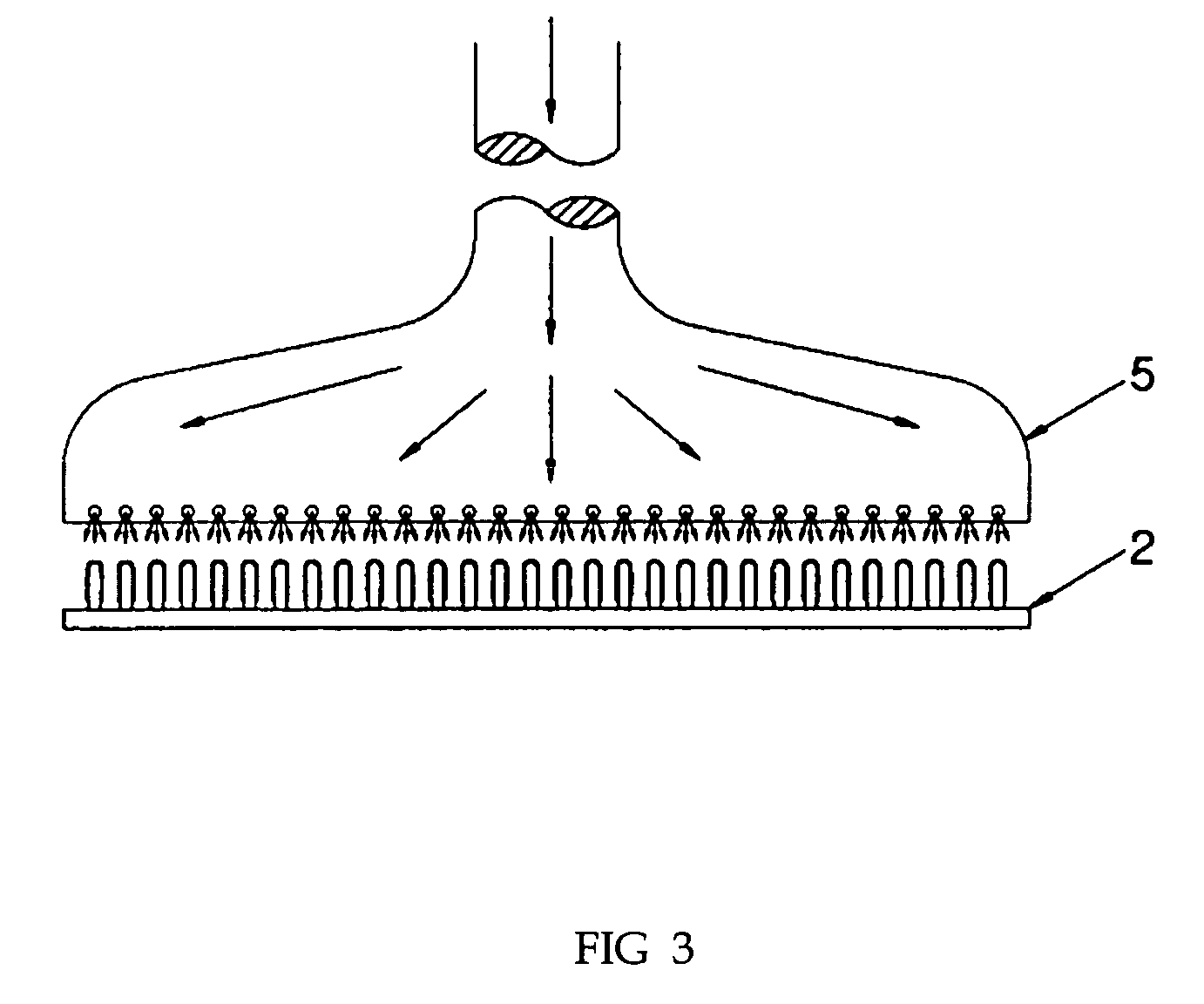

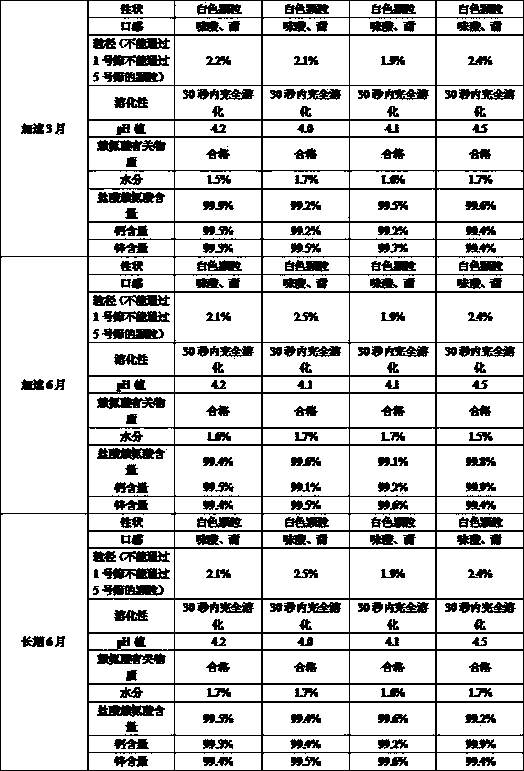

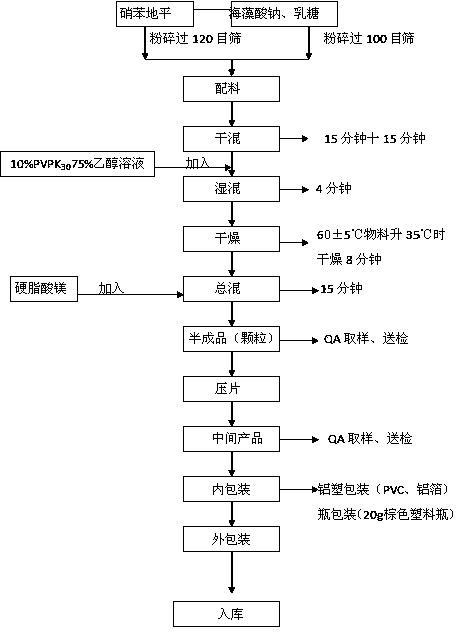

Calcium gluconate zinc gluconate particulate agent preparation method

InactiveCN103417489AImprove solubilityQuality assuranceMetabolism disorderDigestive systemMedicineBiology

The invention discloses a calcium gluconate zinc gluconate particulate agent preparation method. The preparation comprises calcium gluconate, zinc gluconate and lysine hydrochloride of effective doses a pH regulator, an excipient, a sweetener, an adhesive, and a fragrance. The particulate agent provided by the invention has stable quality, good taste, and good administration compliance.

Owner:黄华

Quinoa cereal meal replacement powder

InactiveCN108522962AReplenish evenlyFunction increaseFood ingredient as taste affecting agentNatural extract food ingredientsDiseasePolygonum fagopyrum

The invention discloses quinoa cereal meal replacement powder and a preparation method thereof. The quinoa cereal meal replacement powder is prepared from the following raw materials in parts by weight: 30-40 parts of quinoa, 7-9 parts of polished round-grained rice, 7-8 parts of coix seeds, 6-8 parts of broom corn millets, 6-8 parts of buckwheat, 3-4 parts of red adzuki beans, 3-4 parts of blackbeans, 1-3 parts of mung beans, 2-3 parts of Chinese wolfberry fruits, 2-4 parts of lucid ganoderma, 2-3 parts of Chinese yam, 2-3 parts of haws, 2-4 parts of water chestnuts, 1-2 parts of spinach, 1-2 parts of beet, 4-5 parts of kiwi fruits, 4-5 parts of pineapples, 2-3 parts of calcium gluconate, 2-3 parts of ammonium ferric citrate, 3-5 parts of maltodextrin powder and 3-5 parts of skim milk powder. The quinoa cereal meal replacement powder prepared by mixing the quinoa which serves as a main raw material with multiple cereals, fruits, vegetables and dairy products has a unique taste and rich nutrition for balanced nutrition supplement, can be used for effectively reinforcing the body function performance and regulating the immunity, improving the body stress and preventing diseases andobesity, is suitable for people of all ages for natural health maintenance, and is especially suitable for people losing weight.

Owner:吉林市老爷岭农业发展有限公司

Calcium enriched and knuckle health care food and its preparation method

ActiveCN1475147AGood curative or preventive effectImprove absorption and utilizationFood preparationChemistryCalcium carbonate

A food for supplementing calcium to human body, taking care of joint health, and preventing and curing arthritis is prepared from aminoglucose 15%-80%, calcium preparation one of calcium gluconate, calcium lactate, calcium phosphate and calcium carbonate 15%-80%, and VD 0.1%-5%.

Owner:浙江澳兴生物科技有限公司

Edible collagen jelly and preparation method thereof

ActiveCN103976202AUnique formulaGreat tasteFood ingredient as thickening agentFood preparationBiotechnologyPagoda tree

The invention discloses edible collagen jelly and a preparation method thereof. The jelly is prepared from the raw materials in parts by weight: 100 parts of bone collagen, 15-20 parts of lentinula edodes, 5-10 parts of hericium erinaceus, 15-20 parts of chestnut inside peel, 10-15 parts of tuckahoe, 20-25 parts of Chinese goosebeery, 15-20 parts of spinach, 1-5 parts of pagoda tree flower, 5-10 parts of white gourd seed, 10-15 parts of lotus root, 15-20 parts of pomelo peel, 10-15 parts of sweet potato, 5-10 parts of wheat bran, 5-10 parts of red bean, 10-15 parts of seaweed, 1-5 parts of fishbone, 1-5 parts of fishskin, 1-5 parts of fishscale, 1-5 parts of calcium gluconate and 0.1-0.3 part of zinc gluconate. According to the jelly and the preparation method thereof, the formula is unique, and the collagen is prepared into a jelly shape, so that the oral taking and carrying are more convenient; through the synergism of all the ingredients, the jelly disclosed by the invention can play roles in strengthening immunity, expelling toxin, protecting the liver, relaxing the bowels, repairing, resisting oxidation and the like, and has very good effects on maintaining beauty and keeping young and caring health.

Owner:SHANDONG HAIYU BIOLOGICAL CO LTD

Coenzyme Q10 gum for protecting teeth, strengthening brain and removing odor

InactiveCN105920202ASatisfied with the effectEasy to solveNervous disorderDigestive systemVitamin b6Treatment effect

The invention relates to a coenzyme Q10 gum for protecting teeth, strengthening brain and removing odor. The gum can play the effects of protecting teeth, eliminating halitosis, promoting the development of nerve cells, repairing, and strengthening brain on dental caries, gingivitis, periodontitis and other oral diseases. The coenzyme Q10 gum contains tea polyphenols, xylitol, glycyrrhizin, coenzyme Q10, lipoic acid, taurine, almond oil, glucosamine, calcium gluconate, vitamin B1, vitamin B6, vitamin D and menthol. The product has good prevention and treatment effect on dental caries and oral diseases, can relieve inflammation and pain, strengthen brain, strengthen brain, prevent and treat dental caries, gingivitis, periodontitis, oral ulcer and eliminate halitosis. Through preliminary clinical observation, the gum has very satisfied effect, and is a safe and reliable health product.

Owner:广东润和生物科技有限公司 +1

Platelet-rich gel and preparation method thereof

InactiveCN110664735APromote cell renewalPromote healingOrganic active ingredientsPeptide/protein ingredientsSodium bicarbonateVenous blood

The invention discloses a platelet-rich gel and a preparation method thereof. The preparation method comprises the following steps that an ethylenediamine tetracetic acid sodium solution is prepared,specifically, sterile water for injection is taken, sodium bicarbonate is added into the sterile water, the pH value of the sterile water for injection is adjusted to 7.8, then ethylenediamine tetracetic acid sodium is added into the mixture and mixed evenly, and the ethylenediamine tetracetic acid sodium solution with the molarity being 0.25 mol / L is prepared; peripheral venous blood of a patientis collected by a container containing the ethylenediamine tetracetic acid sodium solution, centrifugation is conducted, and platelet-rich plasma is prepared; thrombin lyophilized powder and calciumgluconate with the mass concentration being 10% are taken, and the thrombin lyophilized powder and the calcium gluconate are mixed evenly according to the ratio of 1ml of 10% calcium gluconate for every 1000 U of the thrombin lyophilized powder, and a thrombin solution is prepared. The platelet-rich plasma is prepared by mixing the platelet-rich plasma and the thrombin solution according to the volume ratio of 10:1; and the platelet-rich plasma and the thrombin solution are mixed evenly according to the volume ratio of 10:1, and the platelet-rich gel is prepared. According to the platelet-richgel, the therapeutic effect is good, and wound healing can be effectively promoted, and treatment time is shortened.

Owner:内江市第一人民医院

Ribose functional food

InactiveCN103371317ARelieve fatigueImprove solubilityFood preparationBiotechnologyCoronary heart disease

The invention provides a ribose functional food. The ribose functional food comprises the following components in parts by weight: 30-70 parts of the D-ribose, 10-60 parts of the L-propionylcarnitine, 0.02-10 parts of the L-malic acid, 0.17-0.5 parts of the coenzyme Q10 and 5-20 parts of the maltodextrin which are taken as main raw materials; one or more of magnesium gluconate, calcium gluconate, selenomethionine, taurine, creatine monohydrate, NADH (NicotinamideAdenine Dinucleotide), glutamine, glycine, spices and edible pigments are selected as auxiliary materials to be mixed to prepare oral preparations including tablets, capsules, granules and oral solutions. The invention provides the functional food capable of increasing the energy in the body, accelerating the recovery of fatigue, increasing the myocardium energy, reducing the oxygen consumption amount and accelerating the recovery of an organism aiming at people who are occupied in high-strength physical exercise or heavy physical labor, coronary heart disease prognostic patients, old people and patients of some chronic diseases.

Owner:山东邦奥创业生物科技有限公司

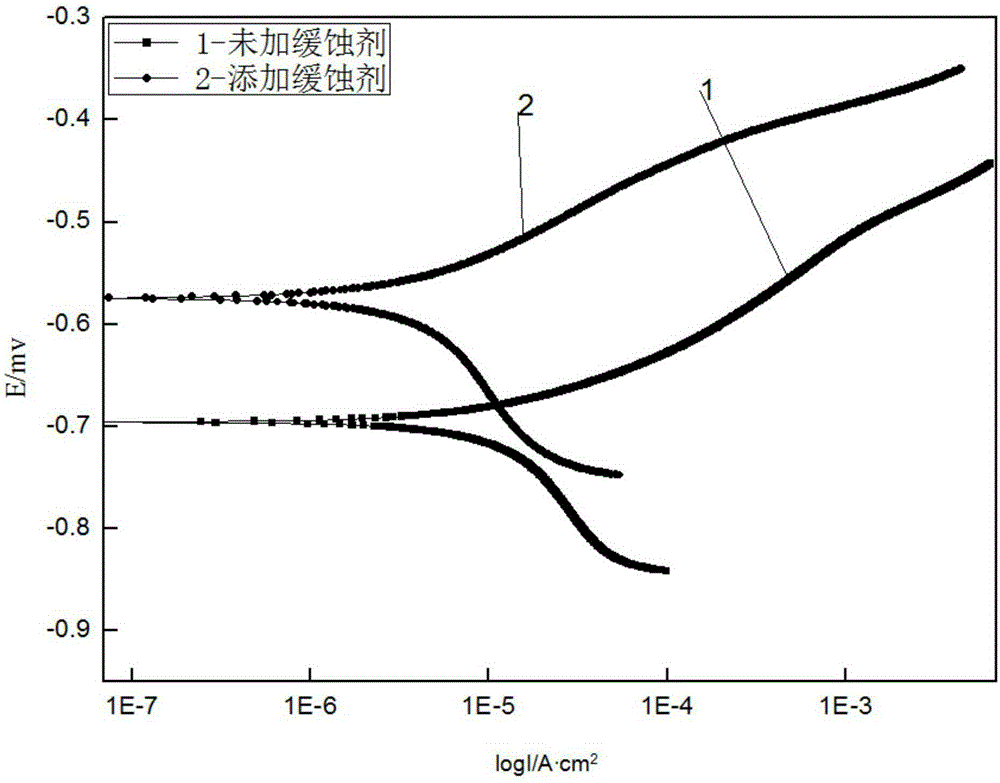

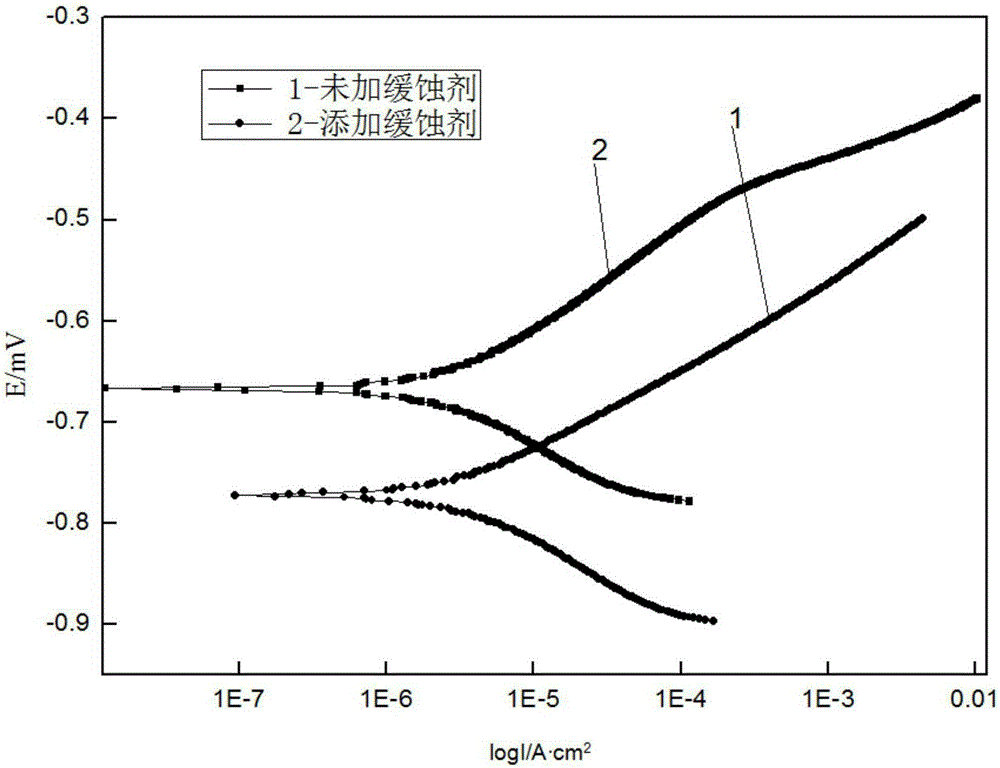

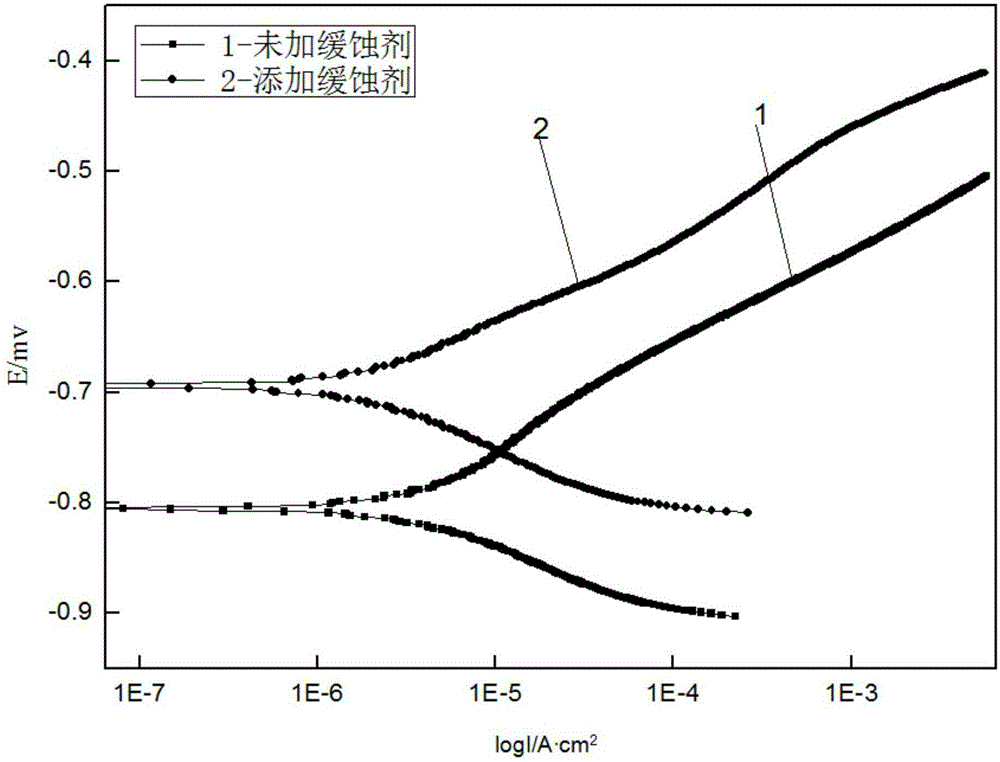

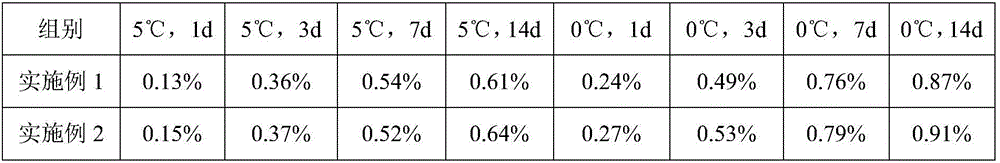

Natural seawater molybdate carbon steel composite corrosion inhibitor

The invention relates to a natural seawater molybdate carbon steel composite corrosion inhibitor, which is characterized in that per liter of the seawater comprises 20-100 mg of sodium molybdate, 60-140 mg of calcium gluconate, 60-140 mg of zinc sulfate, 20-100 mg of sodium polyphosphate, and 20-100 mg of benzotriazole.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Method for preparing calcium gluconate injection

InactiveCN106619500AImprove solubilityQuality improvementOrganic active ingredientsMetabolism disorderSodium acetateSodium acetrizoate

The invention belongs to the technical field of medicament preparation, and particularly relates to a method for preparing a calcium gluconate injection. Every liter of the injection contains 90 to 110g of calcium gluconate, 3 to 40g of calcium acetate, 0.5 to 2g of sodium acetate, 0.5 to 6ml of glacial acetic acid, 1 to 10g of sodium hydroxide and the balance of water for injection. Compared with the prior art, the method has the advantages that the sodium acetate and the calcium acetate are added in a prescription process of the calcium gluconate injection, so that the dissolution-promoting effect of the calcium gluconate is enhanced; the sodium acetate and the calcium acetate are taken as a co-solvent and a stabilizer of the calcium gluconate, so that the stability of the calcium gluconate injection is enhanced. As proved by long-time review of stability, crystals are basically not produced in a storage period, particularly under a low-temperature condition, and stable quality is achieved.

Owner:CISEN PHARMA

Sea cucumber capsule and preparation process thereof

The invention relates to a sea cucumber capsule and a preparation process thereof. The sea cucumber capsule comprises, 500-1000 parts of sea cucumber, 50-100 parts of mythic fungus, 50-80 parts of seabuckthorn fruit leaves, 50-80 parts of total saponin of ginseng stems and leaves, 50-80 parts of hawthorn, 50-80 parts of common jujube, 50-80 parts of medlar, 10-20 parts of lohanguo siraitia fruit, 50-80 parts of calcium gluconate, and 50-80 parts of vitamin C. The preparation process comprises 11 steps of raw material purification, vacuum freeze drying, coarse crushing, ultrafine crushing, microwave-assisted enzymolysis, enzyme inactivation, filtration, desalination, accessory seasoning liquid processing, material preparing and pelletizing, and sterilization and filling. The obtained sea cucumber capsule has characteristics of reasonable formulation and stable property, and has effects of exact blood fat lowering, blood sugar lowering and blood pressure lowering, wherein the blood fat lowering effect is especially prominent.

Owner:QINGDAO JIARILONG SEAFOOD

Effervescence tablet beverage with fat-reducing function and its preparing process

ActiveCN1907058AWith weight loss functionHas the function of losing weight and anti-fatiguePre-extraction tea treatmentPlant ingredientsDiseaseAdditive ingredient

The invention discloses an effervescent beverage with fat-reducing function comprising main ingredients and auxiliary materials, wherein the main ingredients include (by weight portions) green apple essence 10-50, green tea extract 10-30, Hypericum perforatum extract 10-30, calcium gluconate 10-30, zinc gluconate 10-30, and ferrous fumarate 10-30, the auxiliary materials include (by weight ratio) lemon acid 5-20, sodium hydrogen carbonate 5-20, soluble starch 25-40, sweetener 3-8, flavoring agent 0.5-3, preservative agent 1-2. The preparing process consists of mixing main ingredients homogeneously, charging auxiliary materials, stirring homogeneously, moistening and granulating, sieving, charging disintegrating agent, lubricating agent, mixing homogenously, tabletting, dressing, checking and packaging.

Owner:GUIZHOU SHENQI PHARMA RES INST

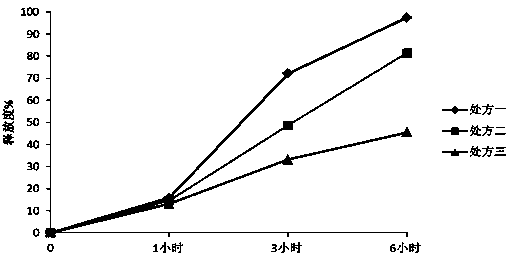

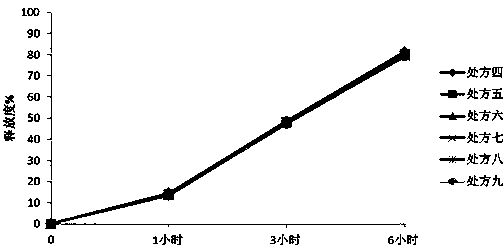

Nifedipine sustained release tablet and preparation method thereof

ActiveCN103349651AProlong the action timeImprove bioavailabilityAntibacterial agentsOrganic active ingredientsNifedipineProlonged-release tablet

The invention provides a nifedipine sustained release tablet and a preparation method thereof. The nifedipine sustained release tablet is prepared from nifedipine, sodium alginate, lactose, a PVP-K30 ethanol solution, magnesium stearate and calcium gluconate. The preparation method comprises the following steps: preparing raw materials, preparing the PVP-K30 ethanol solution, thoroughly mixing the raw materials according to the prescribed amount, then adding an appropriate amount of PVP-K30 ethanol solution, and performing mixed granulation; after drying, adding a right amount of magnesium stearate, mixing totally, and then performing tabletting and packaging. The nifedipine sustained release tablet provided by the invention has the advantages of good safety, dissolution curve and stability, low cost and the like.

Owner:DEZHOU BOCHENG PHARMA

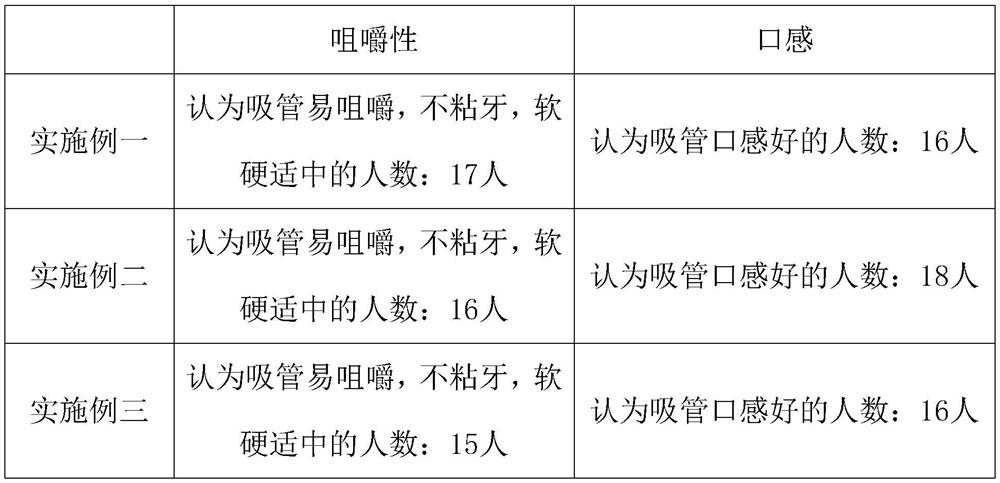

Degradable environment-friendly straw and preparation method thereof

ActiveCN111875853ANo side effectsImprove antibacterial propertiesCoatingsBiotechnologyPhenolic content in tea

The invention relates to the technical field of straws, and provides a degradable environment-friendly straw and a preparation method thereof, the degradable environment-friendly straw comprises the following components by weight: 2-8 parts of sodium alginate, 0.5-5 parts of pectin, 0.5-2 parts of welan gum, 8-30 parts of modified starch, 5-10 parts of a plasticizer, 0.5-1.5 parts of tea polyphenol, 0.4-1.2 parts of chitosan oligosaccharide, 0.2-1 part of calcium gluconate, 0.5-2 part of tartaric acid and 50-100 parts of deionized water. The straw is safe and sanitary, free of toxic and side effects, environmentally friendly, edible, easy to degrade, suitable for wide application and popularization and capable of replacing a disposable plastic straw; therefore, the problems that in the prior art, a disposable plastic straw is difficult to degrade, and environmental and marine ecological pollution is prone to being caused are solved.

Owner:施竣元

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com