Degradable environment-friendly straw and preparation method thereof

An environment-friendly straw technology, applied in the direction of coating, etc., can solve the problems of environmental and marine ecological pollution, disposable plastic straws are difficult to degrade, etc., and achieve high biodegradability, prevent gel hardening, and good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

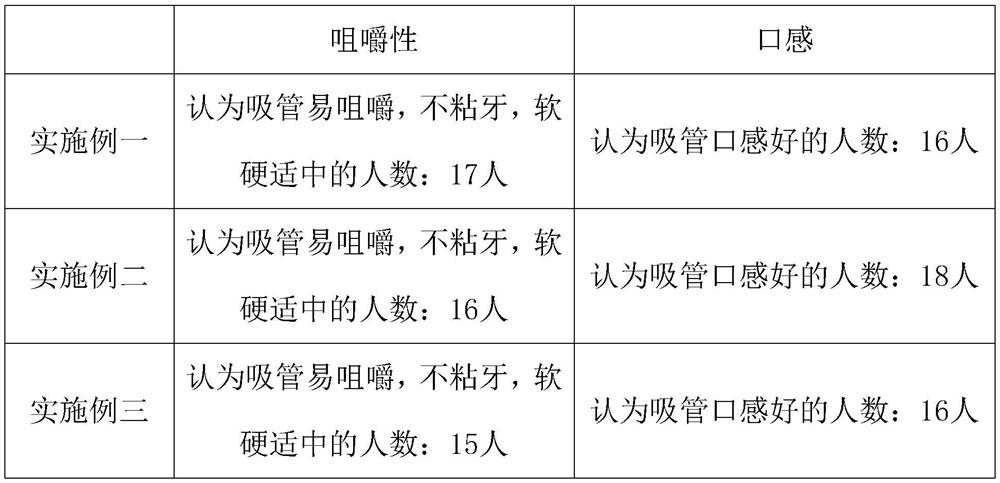

Examples

Embodiment 1

[0027] A degradable and environment-friendly straw, comprising the following components in parts by weight: 2 parts of sodium alginate, 0.5 parts of pectin, 0.5 parts of Wenlun gum, 8 parts of modified starch, 5 parts of fructose, 0.5 parts of tea polyphenols, 0.4 part of chitosan oligosaccharide, 0.2 part of calcium gluconate, 0.5 part of tartaric acid, 0.01 part of brilliant blue, 50 parts of deionized water. The preparation method of the modified starch is as follows: dissolving wheat starch in sodium hydroxide solution, the quality of which is 1.5 times that of ordinary starch, then adding propylene oxide, stirring and reacting at 55°C for 3 hours, then adding Maleic anhydride, stirred and reacted for 1 hour, washed, suction filtered, and dried to obtain modified starch, wherein the mass ratio of ordinary starch, propylene oxide, and maleic anhydride is 10:1.8:1.2.

[0028] A preparation method of a degradable environment-friendly straw, comprising the steps of:

[0029] ...

Embodiment 2

[0035] A degradable and environment-friendly straw, comprising the following components in parts by weight: 5 parts of sodium alginate, 3 parts of pectin, 1.2 parts of Wenlun gum, 20 parts of modified starch, 8 parts of sorbitol, and 1 part of tea polyphenol 0.8 parts, 0.8 parts of chitosan oligosaccharide, 0.6 parts of calcium gluconate, 1.2 parts of tartaric acid, 0.2 parts of lemon yellow, 75 parts of deionized water. The preparation method of the modified starch is as follows: dissolving potato starch in sodium hydroxide solution whose quality is three times that of ordinary starch, then adding propylene oxide, stirring and reacting at 60°C for 4 hours, then adding Maleic anhydride, stirred and reacted for 1.5h, washed, suction filtered, and dried to obtain modified starch, wherein the mass ratio of ordinary starch, propylene oxide, and maleic anhydride was 11:2.4:1.8.

[0036] A preparation method of a degradable environment-friendly straw, comprising the steps of:

[00...

Embodiment 3

[0043] A degradable and environment-friendly straw, comprising the following components in parts by weight: 8 parts of sodium alginate, 5 parts of pectin, 2 parts of Wenlun gum, 30 parts of modified starch, 10 parts of glycerin, 1.5 parts of tea polyphenols, 1.2 parts of chitosan oligosaccharide, 1 part of calcium gluconate, 2 parts of tartaric acid, 0.5 part of mastia, 100 parts of deionized water. The preparation method of the modified starch is as follows: dissolving sweet potato starch in sodium hydroxide solution, the quality of which is 5 times that of ordinary starch, then adding propylene oxide, stirring and reacting at 65°C for 5 hours, and then adding Maleic anhydride, stirred and reacted for 2 hours, washed, suction filtered, and dried to obtain modified starch, wherein the mass ratio of ordinary starch, propylene oxide, and maleic anhydride was 12:3:2.4.

[0044] A preparation method of a degradable environment-friendly straw, comprising the steps of:

[0045] (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com