Natural seawater molybdate carbon steel composite corrosion inhibitor

A composite corrosion inhibitor and molybdate technology, applied in the field of carbon steel corrosion inhibitors, can solve problems such as limited effect, and achieve the effects of inhibiting adsorption, high corrosion inhibition efficiency, and inhibiting pitting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

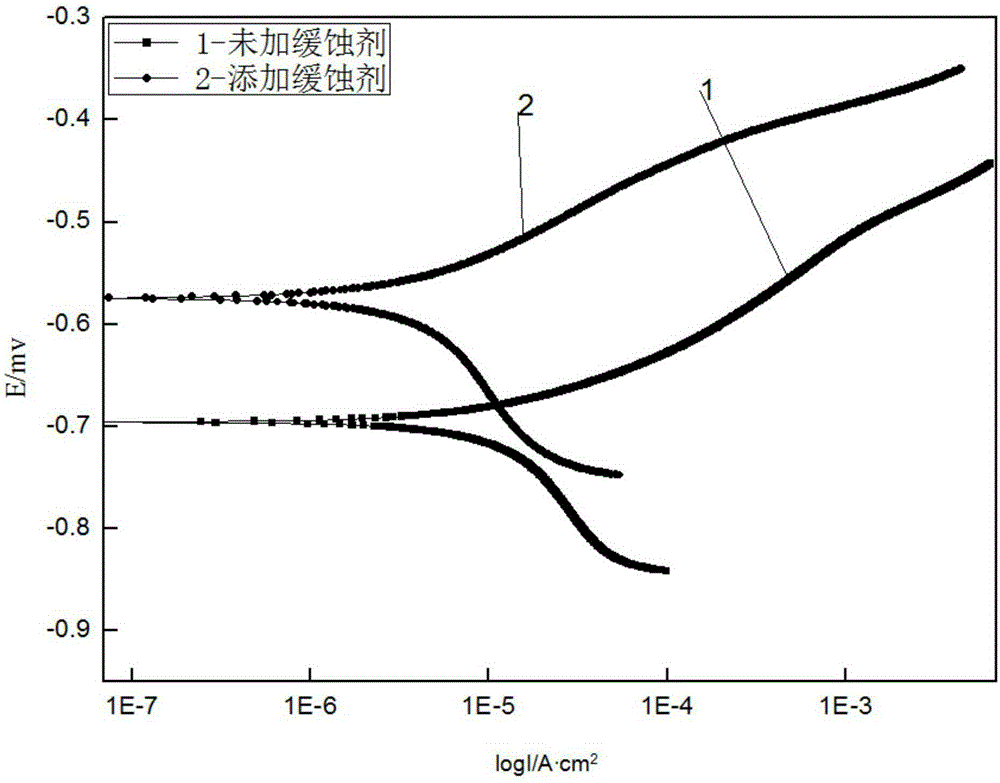

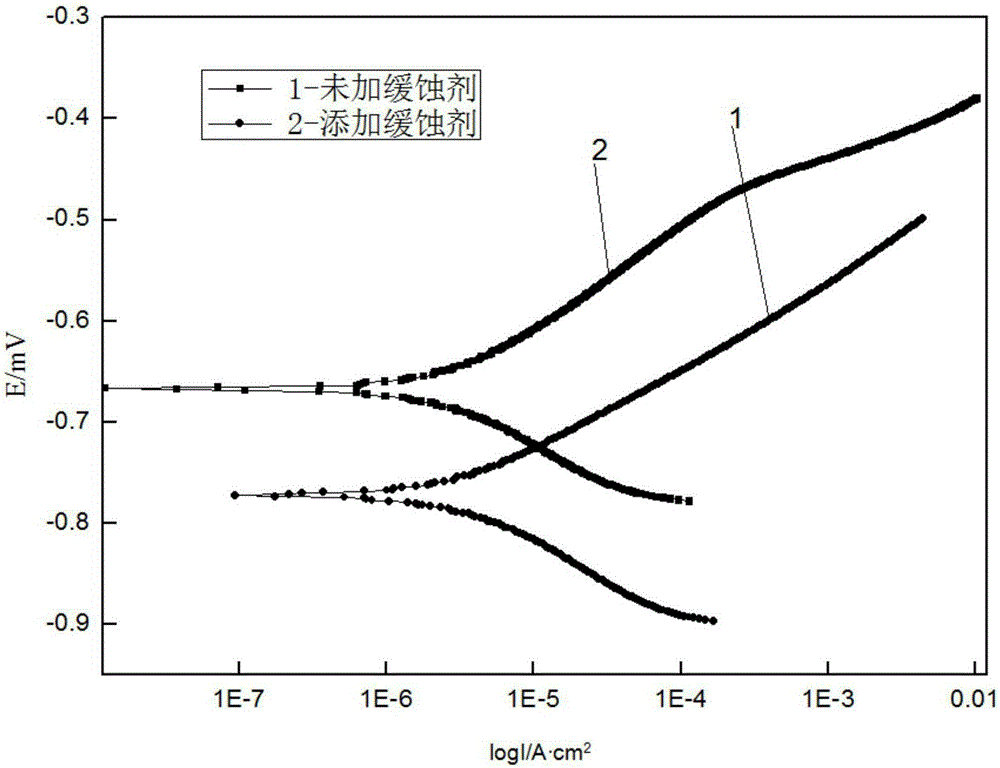

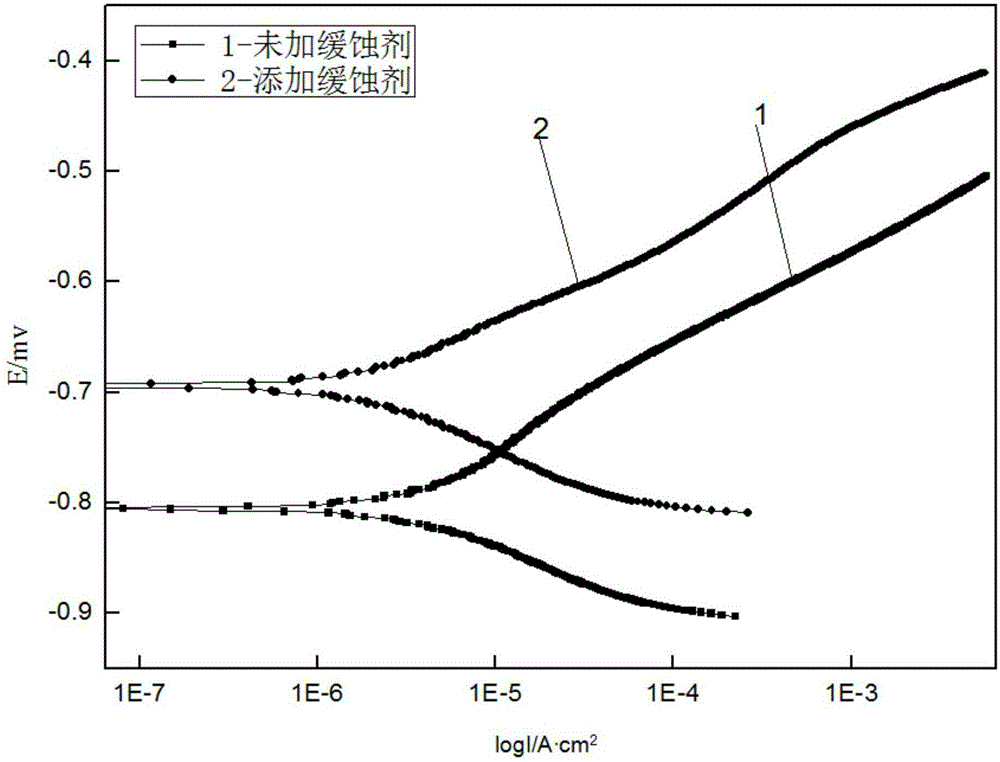

Image

Examples

Embodiment 1~5

[0024] A composite corrosion inhibitor for molybdate carbon steel in natural seawater, consisting of the following components: calcium gluconate 100mg / L, zinc sulfate 100mg / L, sodium polyphosphate 20mg / L, benzotriazole 40mg / L L, sodium molybdate is respectively 20mg / L (embodiment 1), 40mg / L (embodiment 2), 60mg / L (embodiment 3), 80mg / L (embodiment 4), 100mg / L (embodiment 5 ). The above components were mixed and stirred for 20 minutes, then dissolved in 1L of seawater, and the carbon steel material was soaked in seawater at 25°C with the addition of a composite corrosion inhibitor for 15 days.

[0025] After immersion, calculate the corrosion inhibition efficiency according to the method described in the national standard GB / T18175-2000 of the People's Republic of China, specifically: according to the change of the sample weight before and after the experiment, calculate the corrosion rate by the weight loss method, so as to Determine the corrosion resistance of metal material...

Embodiment 6~10

[0035] A composite corrosion inhibitor for molybdate carbon steel in natural seawater, consisting of the following components: sodium molybdate 20mg / L, zinc sulfate 100mg / L, sodium polyphosphate 20mg / L, benzotriazole 40mg / L L, calcium gluconate is respectively 60mg / L (embodiment 6), 80mg / L (embodiment 7), 100mg / L (embodiment 8), 120mg / L (embodiment 9), 140mg / L (embodiment 10 ). The remaining steps are the same as in Examples 1-5, and the measurement results of the corrosion inhibition rate are recorded in Table 2. It can be seen from the results that when the amount of sodium molybdate added is 120mg / L, the corrosion inhibition effect is the best, and the corrosion inhibition efficiency reaches 86.4%.

[0036] Table 2

[0037] Example

Embodiment 11~15

[0039] A composite corrosion inhibitor for molybdate carbon steel in natural seawater, consisting of the following components: sodium molybdate 20mg / L, sodium polyphosphate 20mg / L, calcium gluconate 100mg / L, benzotriazole 40mg / L, zinc sulfate is respectively 60mg / L (embodiment 11), 80mg / L (embodiment 12), 100mg / L (embodiment 13), 120mg / L (embodiment 14), 140mg / L (embodiment 15 ). The rest of the steps are the same as the implementation series 1, and the rest of the steps are the same as in Examples 1-5, and the measurement results of the corrosion inhibition rate are recorded in Table 3.

[0040] table 3

[0041] Example

[0042] It can be seen from the results that in Examples 11-15, when the amount of zinc sulfate added is 120 mg / L, the corrosion inhibition effect is the best, and the corrosion inhibition efficiency reaches 83.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com