Method for preparing D-arabinose

A technology of arabinose and sugar liquid, applied in the field of functional sugar, can solve the problems of high production cost, complicated process, low yield of D-arabinose, etc., and achieve the effect of reducing production cost and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

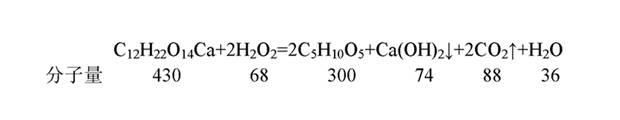

Method used

Image

Examples

Embodiment 1

[0018] (1) Preparation of D-arabinose solution

[0019] Raw material formula adopts weight percentage, and 150 grams of calcium gluconate are dissolved in water, and concentration is 5%, and ferric sulfate is added as catalyst, and the consumption of catalyst is 1.5% of calcium gluconate quality, while stirring, slowly add hydrogen peroxide, peroxidation in hydrogen peroxide The hydrogen concentration was 30%, the reaction temperature was 71°C, the addition rate of hydrogen peroxide was 30 mL / h, and the equivalent of hydrogen peroxide was 6 times that of calcium gluconate.

[0020] (2) Refining of D-arabinose solution

[0021] The D-arabinose solution prepared in step (1) is filtered to remove the insoluble matter produced by the reaction. The insoluble matter is slightly soluble in water, and sodium carbonate is added to the insoluble matter solution to produce a white precipitate, which dissolves in dilute hydrochloric acid and produces a large number of bubbles. Combined w...

Embodiment 2

[0032] The raw material formula adopts weight percentage, and 235 grams of calcium gluconate are dissolved in water, and concentration is 30%, add ferric sulfate as catalyst, the consumption of catalyst is 4.5% of calcium gluconate quality, while stirring, slowly add hydrogen peroxide. The concentration of hydrogen peroxide in hydrogen peroxide was 30%, the reaction temperature was 75°C, the rate of adding hydrogen peroxide was 150 mL / h, and the equivalent of hydrogen peroxide was 10 times that of calcium gluconate. The reacted D-arabinose solution was filtered to remove calcium hydroxide. At 80°C, slowly add 30% sulfuric acid solution to the sugar solution, stir slowly, and precipitate occurs, then filter. The sugar solution passes through the ion exchange resin. At a temperature of 75°C, concentrate in vacuo to a solid content of 43%. After chromatographic separation, the D-arabinose sugar liquid component and miscellaneous sugar components are obtained. Among them, the D...

Embodiment 3

[0034] The raw material formula adopts weight percentage, and 400 grams of calcium gluconate is dissolved in water, and concentration is 20%, and ferric sulfate is added as catalyst, and the consumption of catalyst is 3% of calcium gluconate mass, and hydrogen peroxide is slowly added while stirring. The concentration of hydrogen peroxide in hydrogen peroxide was 30%, the reaction temperature was 75°C, the rate of adding hydrogen peroxide was 100 mL / h, and the equivalent of hydrogen peroxide was 7 times that of calcium gluconate. The reacted D-arabinose solution was filtered to remove calcium hydroxide. At 80°C, slowly add 20% sulfuric acid solution to the sugar solution, stir slowly, and precipitate occurs, then filter. The sugar solution passes through the ion exchange resin. At 75°C, concentrate in vacuo to a solid content of 45%. After chromatographic separation, the D-arabinose sugar liquid component and miscellaneous sugar components are obtained. Among them, the D-ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com