Preparation method for reducing hardness of dietary fiber chewable tablets

A technology of dietary fiber and bamboo shoot dietary fiber, which is applied in the field of food processing to achieve the effects of convenient consumption, good taste, and simple operation of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation of embodiment 1 bamboo shoot dietary fiber powder

[0034] Wash the fresh bamboo shoots to remove impurities, crush them into a slurry, then add mixed enzymes (high-temperature α-amylase and glucoamylase in a ratio of 1:2) according to 0.4% of the mass percentage of raw materials, enzymatically treat at 65°C for 45 minutes, and then rinse with water Wash the filter residue to neutral. Take out the filter residue, add 0.3% protease by mass percentage, enzymatically hydrolyze at 50°C for 45min, and wash with water until neutral. After the filter residue is taken out, it is centrifugally dehydrated, dried at 85°C until the water content is about 7%, and then crushed into 150-mesh bamboo shoot dietary fiber powder.

Embodiment 2

[0035] The preparation of embodiment 2 dried carrot granules

[0036] Take some fresh carrots, wash and remove impurities, and cut into small particles with a width of about 0.3cm. Put the small particles in a pot and cook them with steam for 30 minutes, take them out and cool them down, then put them in an oven and dry them at 85°C for 150 minutes, until the moisture content reaches 7%, take them out for use. A small amount of vegetable essential oil can be added to the small particles before cooking.

Embodiment 3

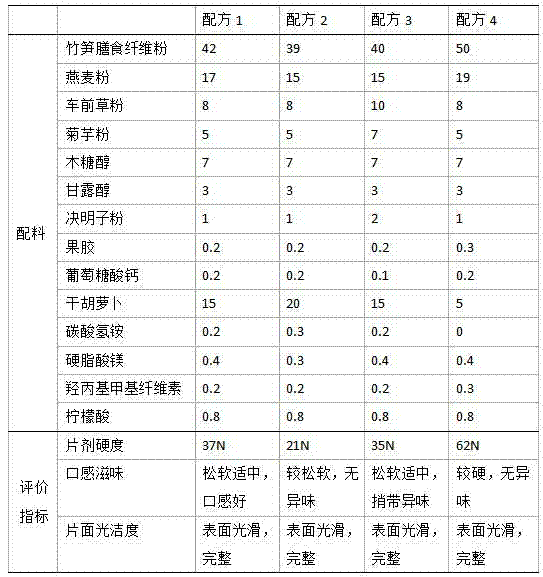

[0037] Example 3 Preparation of Dietary Fiber Chewable Tablets and Screening of the Best Formula of Chewable Tablets (see Table 1 for formula and effect)

[0038] Table 1 Comparison of various formulations of dietary fiber chewable tablets

[0039] (The values in Table 1 are the proportions by weight of each component, and the weight of the chewable tablet is about 0.4-0.6g)

[0040]

[0041] (1) Wash the oats, plantain, Jerusalem artichoke, and cassia seeds and dry them at a temperature of 65-85°C for 120-200 minutes until the moisture content is about 6-10%. After cooling, crush them to a particle size of ≤120 mesh ; Grinding pectin, mannitol, xylitol and calcium gluconate to a particle size of ≤120 mesh;

[0042] (2) The bamboo shoot dietary fiber powder prepared in Example 1 and oat flour, plantain powder, Jerusalem artichoke powder, cassia powder, pectin, mannitol, xylitol, and calcium gluconate were formulated in parts by weight in Table 1. Put it in a V-typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com