Novel catalyst for preparing 4-Iodobenzonitrile

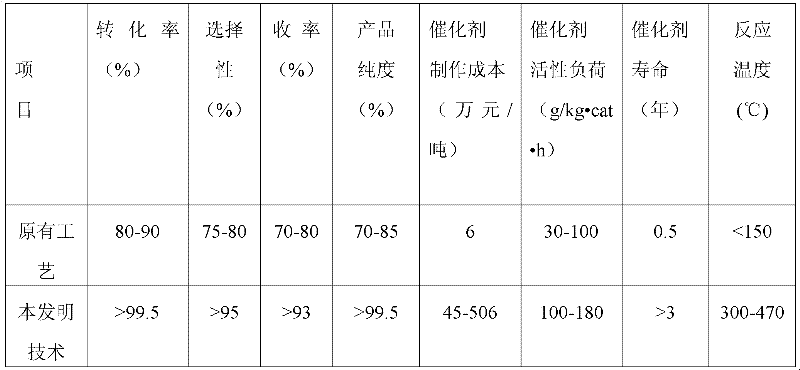

The technology of a catalyst and iodobenzonitrile is applied to the new catalyst of p-iodobenzonitrile and the field of preparation thereof, which can solve the problems of low catalyst selectivity and activity load, easy sintering of the catalyst, short service life and the like, and achieves wide application field and Development prospects, long service life, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] will be composed as Ni a Ti b P c Sb d Bi e o x The oxides or salts of the elements in each component are dissolved separately and mixed. After forming a uniform solution, pour it into 40-mesh coarse-porous microspherical silica gel for immersion and fully stir it. Let it stand and age for 24 hours. After it is air-dried, then The desired catalyst is obtained after activation; wherein a=1 b=1 c=1 d=0.5 e=0.3x=0.3.

Embodiment 2

[0020] will be composed as Ni a Ti b P c Sb d Li e o x The oxides or salts of the elements in each component are dissolved separately and mixed. After forming a uniform solution, pour it into 130-mesh coarse-porous microspherical silica gel for dipping and fully stir it. Let it stand and age for 24 hours. After it is air-dried, then The desired catalyst is obtained after activation; wherein a=1 b=0.5 c=0.5 d=0.5e=0.3 x=0.3.

Embodiment 3

[0022] will be composed as Ni a Mo b P c Sb d Li e o x The oxides or salts of the elements in each component are dissolved separately and mixed. After forming a uniform solution, pour it into 100-mesh coarse-porous microspherical silica gel for immersion and fully stir it. Let it stand and age for 24 hours. After it is air-dried, then The desired catalyst is obtained after activation; wherein a=1 b=0.5 c=0.5 d=0.5e=0.3 x=0.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com