Gas atomizing and spraying device

A spraying equipment and air energy technology, which is applied in the field of air energy atomization spraying equipment, can solve problems affecting the health of operators, environmental protection requirements, environmental pollution, etc., to improve the utilization rate of viscose, avoid pollution, and expand the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

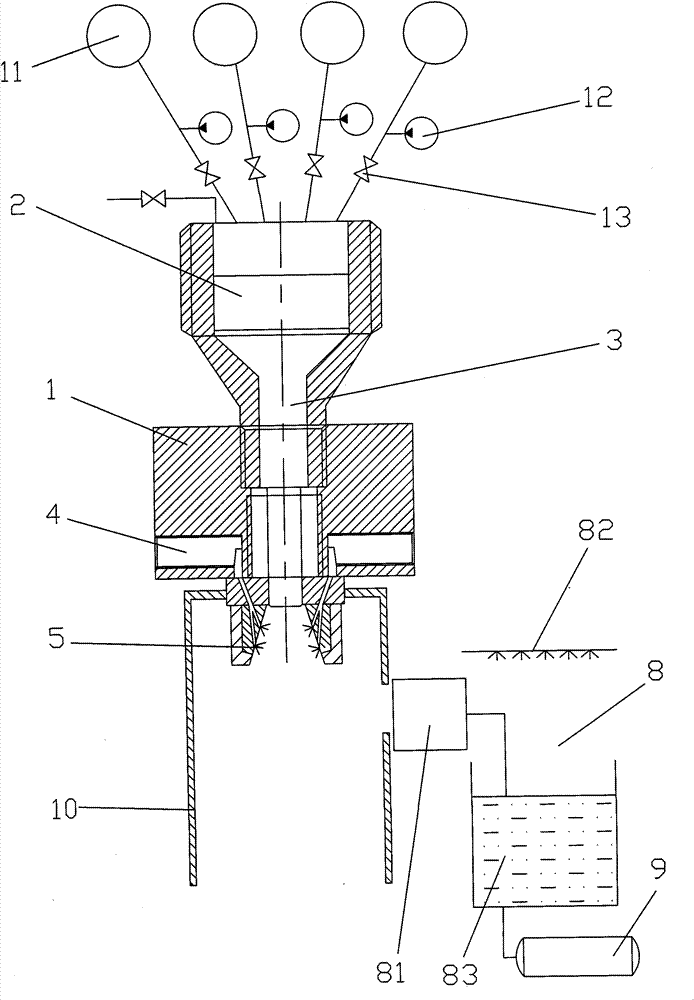

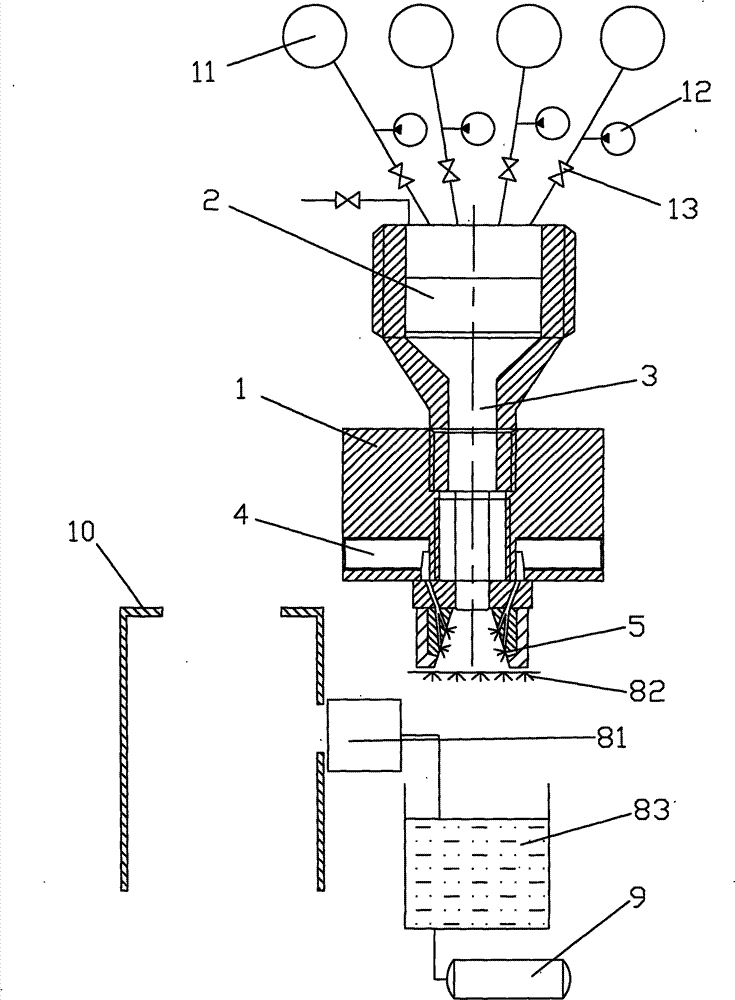

[0020] refer to Figure 1 to Figure 2 , a gas atomization spraying equipment of the present invention, comprising a body 1 and a plurality of storage tanks 11 connected to the body 1 for storing polymer raw materials, the top of the body 1 is provided with a mixing device connected to the storage tanks 11 2. The bottom of the mixing device 2 is provided with at least one feeding channel 3 communicating with the device, and at least one inlet channel 4 is provided on the side wall of the body 1, and the end of the inlet channel 4 is provided with at least one A nozzle 5 is covered at the end of the discharge channel 3, which can disperse and atomize the mixed materials in the discharge channel 3. The gas atomization spraying equipment of the present invention can carry out the mixing, atomization and spraying of rubber materials, which can spray out a uniform adhesive film on the substrate of the coiled material, greatly improving the utilization rate of the adhesive and the qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com