Recycling process of garbage fly ash ash-washing water

A garbage fly ash and ash washing technology, which is applied in the direction of water pollutants, water/sewage multi-stage treatment, heating water/sewage treatment, etc., can solve the problems of environmental pollution and high energy consumption of the process, so as to reduce the cost of comprehensive treatment and improve The effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

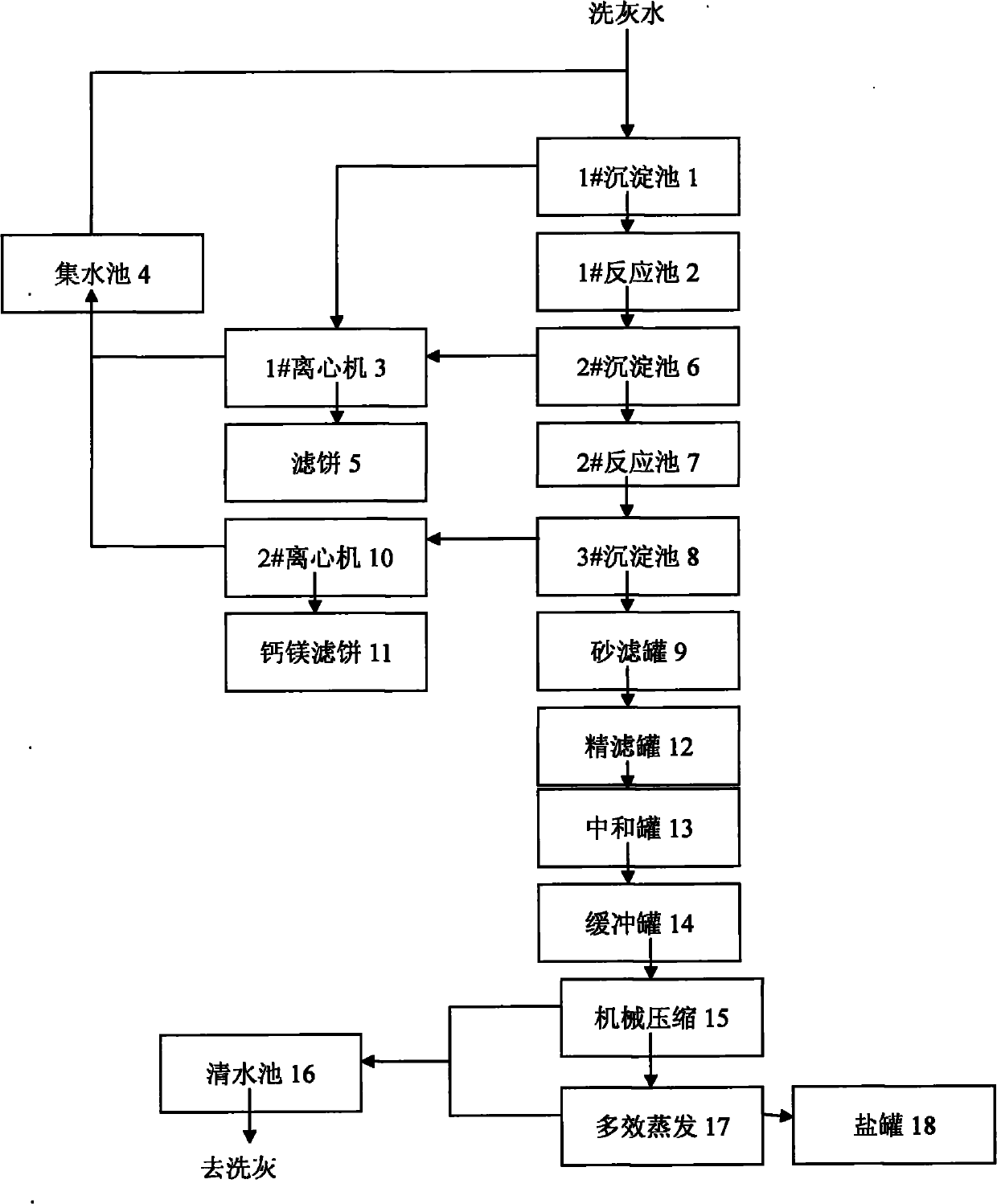

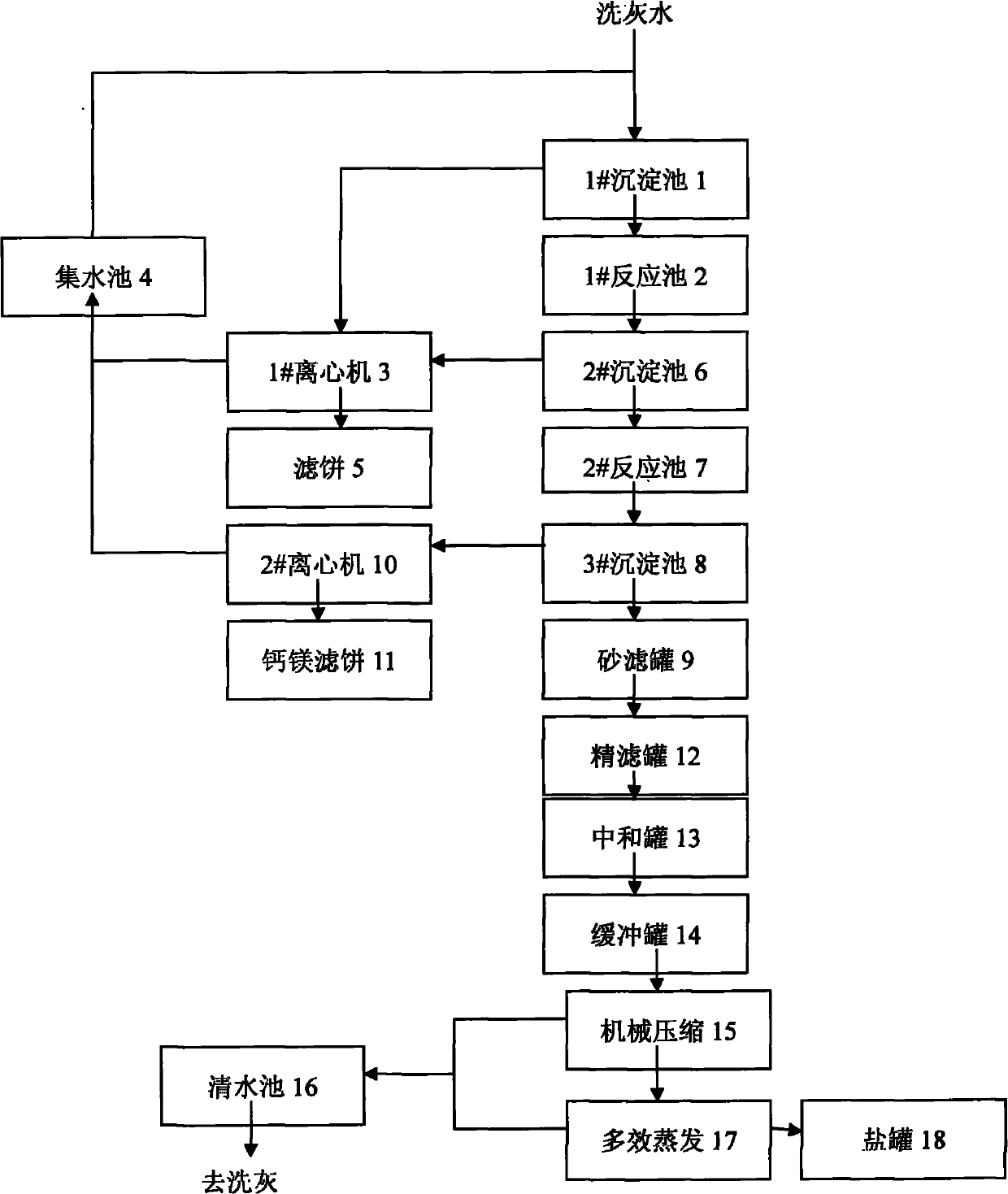

[0019] The present invention is described in detail below in conjunction with accompanying drawing:

[0020] Realize the specific embodiment of the recycling process of a kind of garbage fly ash washing water of the present invention is to carry out suspended solids separation, remove heavy metal ions, remove calcium and magnesium ions, filter, mechanical compression and multi-effect evaporation steps (see figure 1 ):

[0021] Separation of suspended solids: Garbage fly ash washing water enters the 1# sedimentation tank [1] to settle for 4.5 hours, the clarified liquid in the upper layer enters the 1# reaction tank [2] for treatment, and the sewage containing more suspended solids in the lower layer passes through 1 #After the dehydration of the centrifuge [3], the filtrate is collected by the sump [4], pumped to the 1# sedimentation tank [1] for reuse, and the filter cake [5] is landfilled after being solidified by cement;

[0022] In addition to heavy metal ions: add sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com