Notching line-embedding anti-counterfeiting paper and manufacturing method thereof

A manufacturing method and technology of anti-counterfeiting paper, applied in chemical instruments and methods, paper, papermaking, etc., can solve the problems of small security line anti-counterfeiting paper, difficult to manufacture security line anti-counterfeiting coated paper, and manufacturing one-time order quantity, etc. Apply the effect of widening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

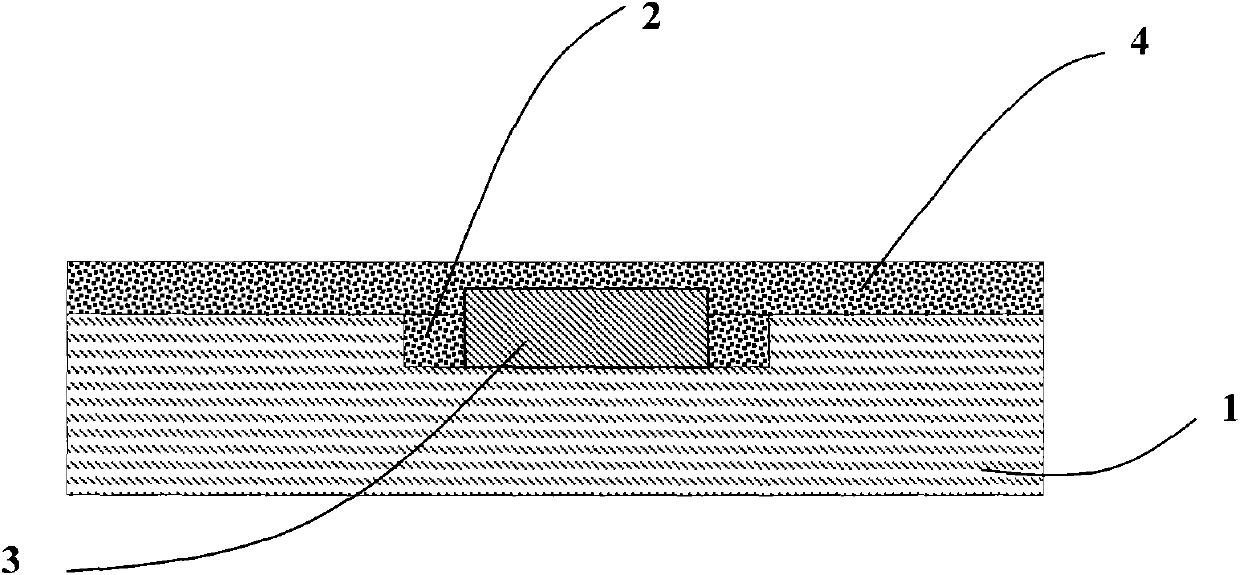

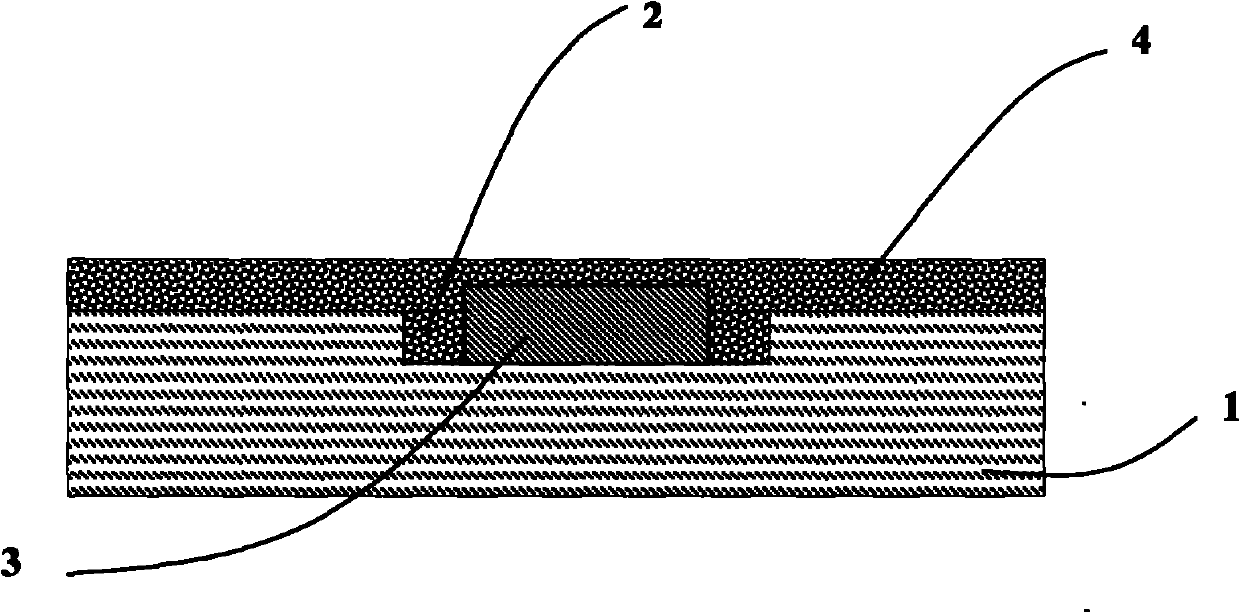

[0030] like figure 1 , figure 2 shown.

[0031] The first step is to purchase a kind of 230 g / m with a width of 1092mm 2 The user-specified brand of white cardboard (1) rolls, and then purchase some paper with a light coating of white paint for use. Purchasing a kind of width again is that 2mm, thickness are the PET golden self-adhesive (or hot-melt adhesive) anti-counterfeit safety thread (3) standby of 22 μm.

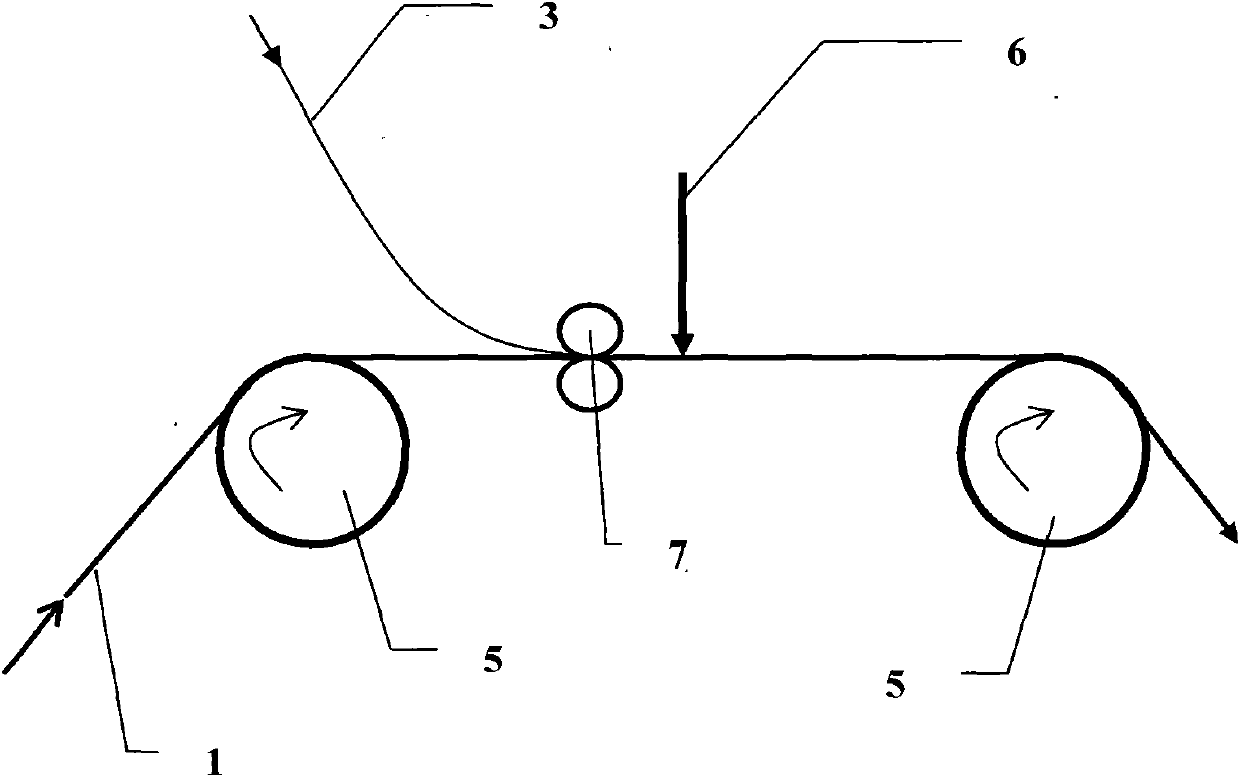

[0032] In the second step, place the white cardboard (1) roll on the unwinding shaft of the coating (compositing) machine with the back facing up, and pass through the coating (compositing) machine to wind up on the winding shaft, and laser engrave it on the appropriate position Machine, aim the laser beam (6) at the back of the jammed paper (1), start the coating (composite) machine to make the paper advance at a speed of 60 m / min, turn on the laser machine, and make the beam (6) on the jammed paper (1) ) to carve grooves (2) with a width of 2.5 mm (slightly wid...

Embodiment 2

[0037] like figure 1 , figure 2 shown.

[0038] The first step is to purchase a kind of 80 g / m with a width of 1092 mm 2 double-sided coated paper (1) rolls. Purchasing a kind of width again is that 1.2mm, thickness are the PET silver self-adhesive anti-counterfeit safety thread (3) of 18 μm.

[0039] The second step is to place the coated paper (1) coil on the unwinding shaft of the coating machine, and pass through the coating machine to wind up on the winding shaft, set up the laser engraving machine at an appropriate position, and align the laser beam (6) Coated paper (1), start the coating machine to make the paper move forward at a speed of 60 m / min, turn on the laser machine, and make the beam (6) engrave a strip with a width of 1.5mm on one side of the coated paper (1) (rather than the safety line slightly wider) and a groove (2) with a depth of 15 μm (slightly shallower than the security line).

[0040] The third step is to draw out the strips of self-adhesive a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com