Infrared thermal imager testing system

A technology of infrared thermal imager and test system, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of reduced reliability, poor temperature uniformity, large error value, etc., to improve stability and reliability, improve Accuracy, the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

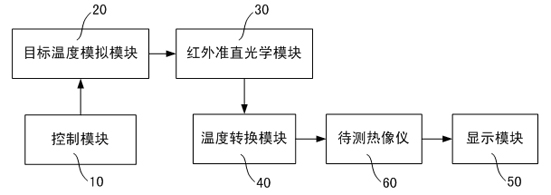

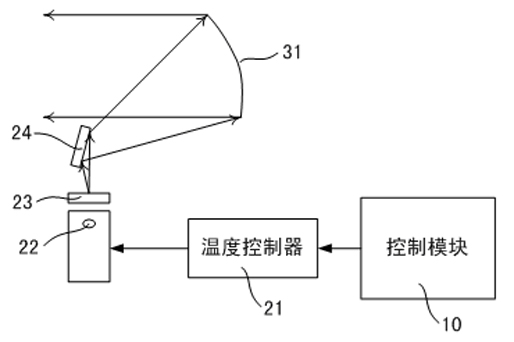

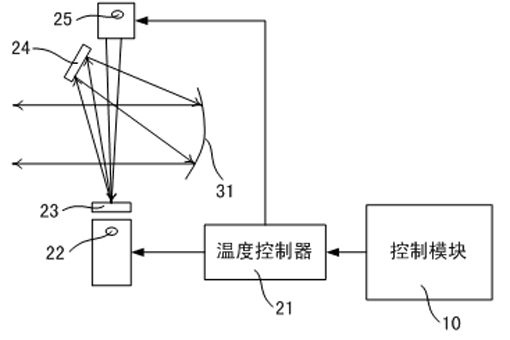

[0049] like figure 1As shown, the infrared thermal imager testing system includes a control module 10 , a target temperature simulation module 20 , an infrared collimation optical module 30 , a temperature conversion module 40 , and a display module 50 . The control module 10 is connected to the target temperature simulation module 20 to control the target temperature simulation module 20 to output a simulated radiation temperature signal; the control module 10 is also connected to the temperature conversion module 40 to control the temperature conversion module 40 to select a test environment. Wherein, the infrared collimation optical module 30 receives the radiation temperature signal, converts the radiation tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com