Optimized control of power plants having air cooled condensers

一种空气冷却式、冷凝器的技术,应用在蒸汽/蒸气冷凝器、电气程序控制、全面工厂控制等方向,能够解决效率低、成本高等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

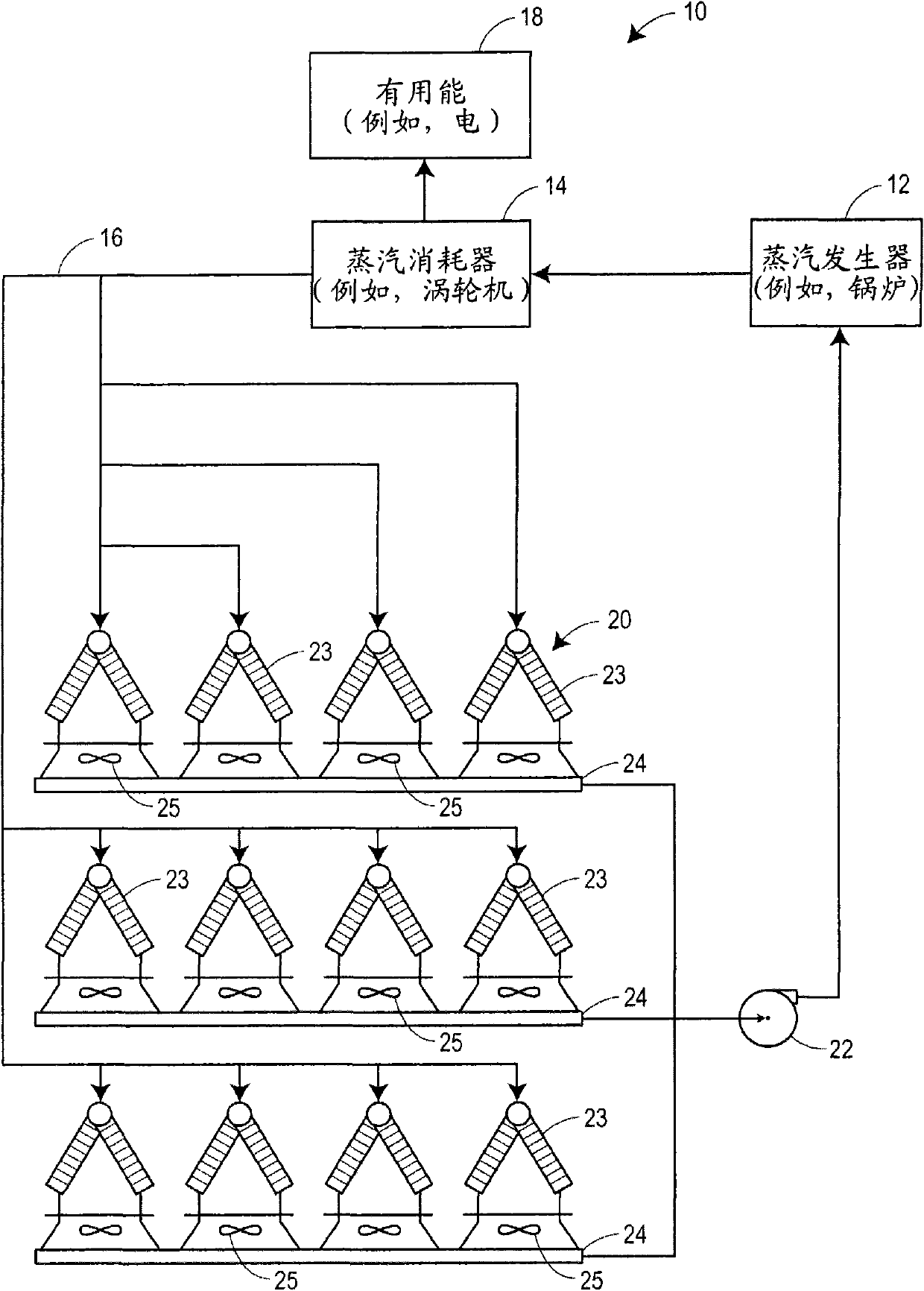

[0020] now refer to figure 1 , a block diagram of a steam cycle of a typical energy generation system 10 comprising a steam generator 12 and a steam consumer 14 (typically in the form of a steam turbine) that produces useful energy 18 . The steam consumer 14 is connected in a closed recirculation loop 16 to a set of electric fan-operated air-cooled condensers 20 . Recirculation loop 16 , which may consist of suitable pipes and conduits for transporting steam and water, also includes one or more boiler feed pumps 22 that return liquid (eg, water) formed in condenser 20 to steam generator 12 .

[0021] Although the steam generator 12 is described herein as a boiler system that operates on thermal principles (e.g., by burning fuel such as petroleum, waste fuel, biomass, wood chips, etc.) to convert water into steam, instead of or in addition to the boiler system Alternatively, other types of steam generators may be used. For example, steam generator 12 may be a fossil fuel boi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com