Protective element and method for manufacturing the same

A technology for protecting components and manufacturing methods, which is applied in the manufacturing of fuses, electrical components, emergency protection devices, etc., can solve problems such as deteriorating the responsiveness of current cut-off actions, and achieve the effect of good responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

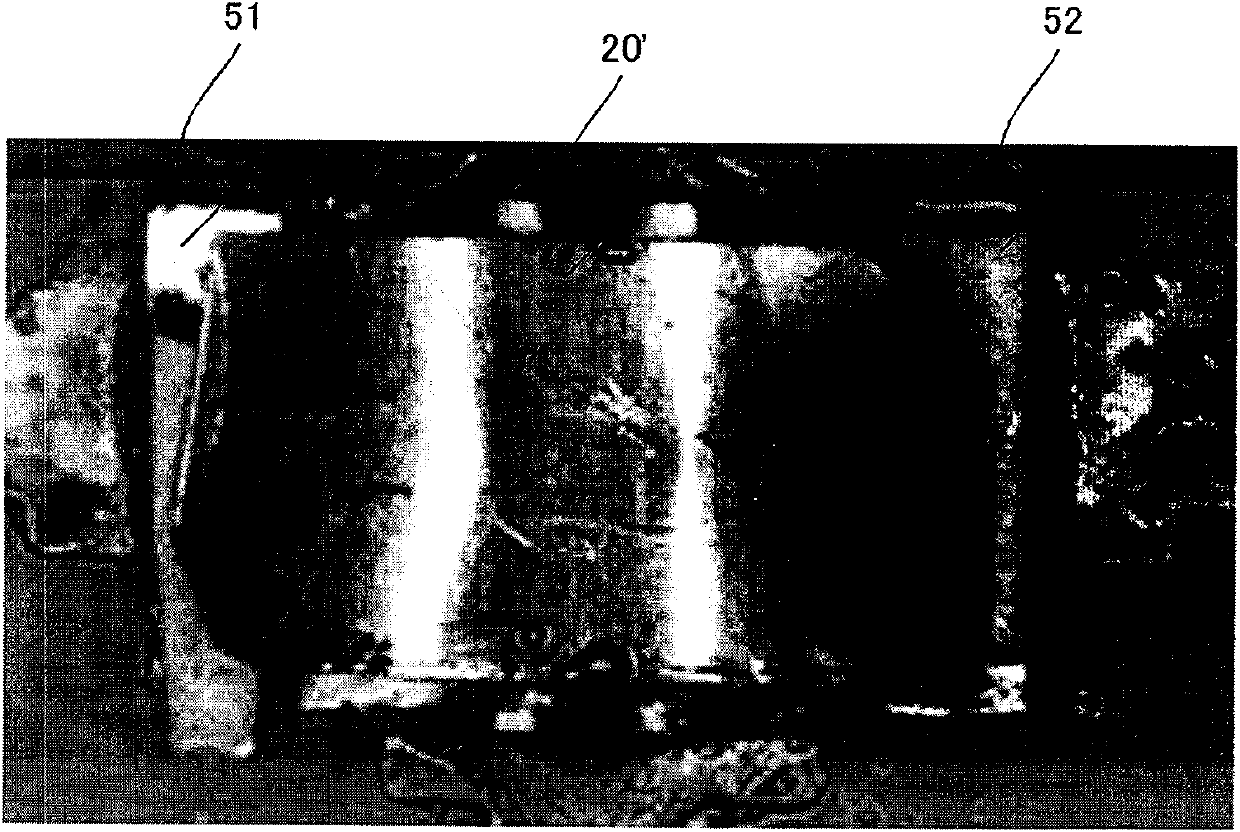

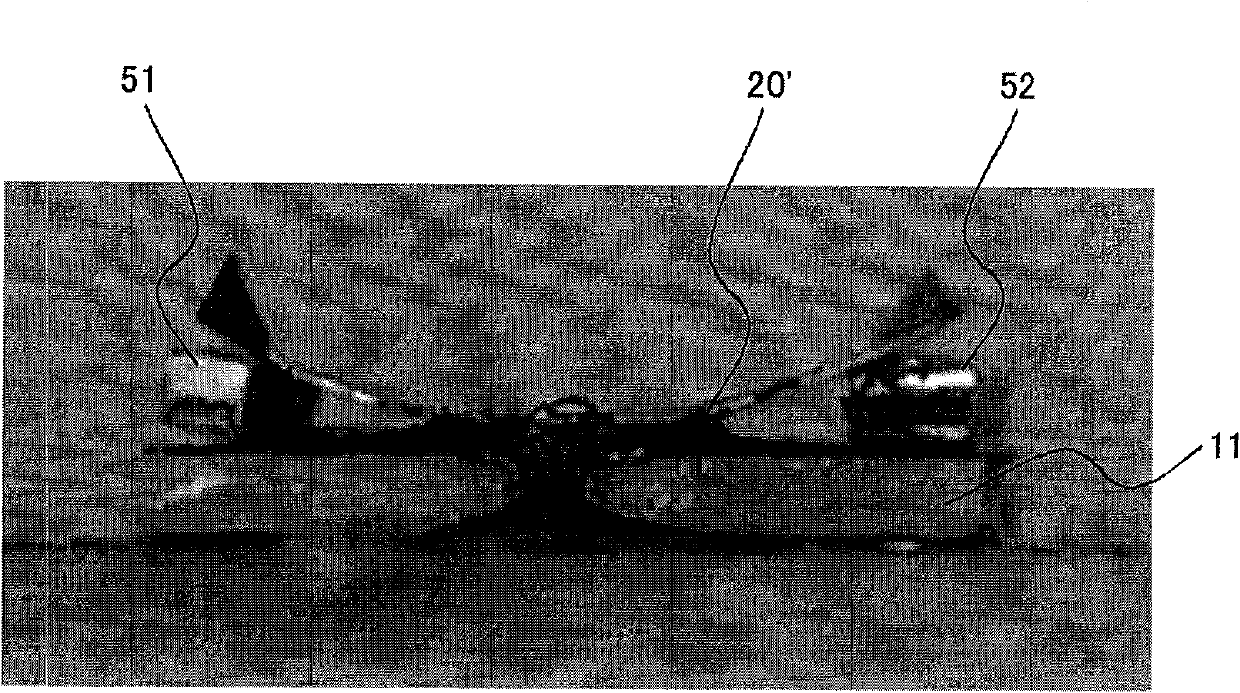

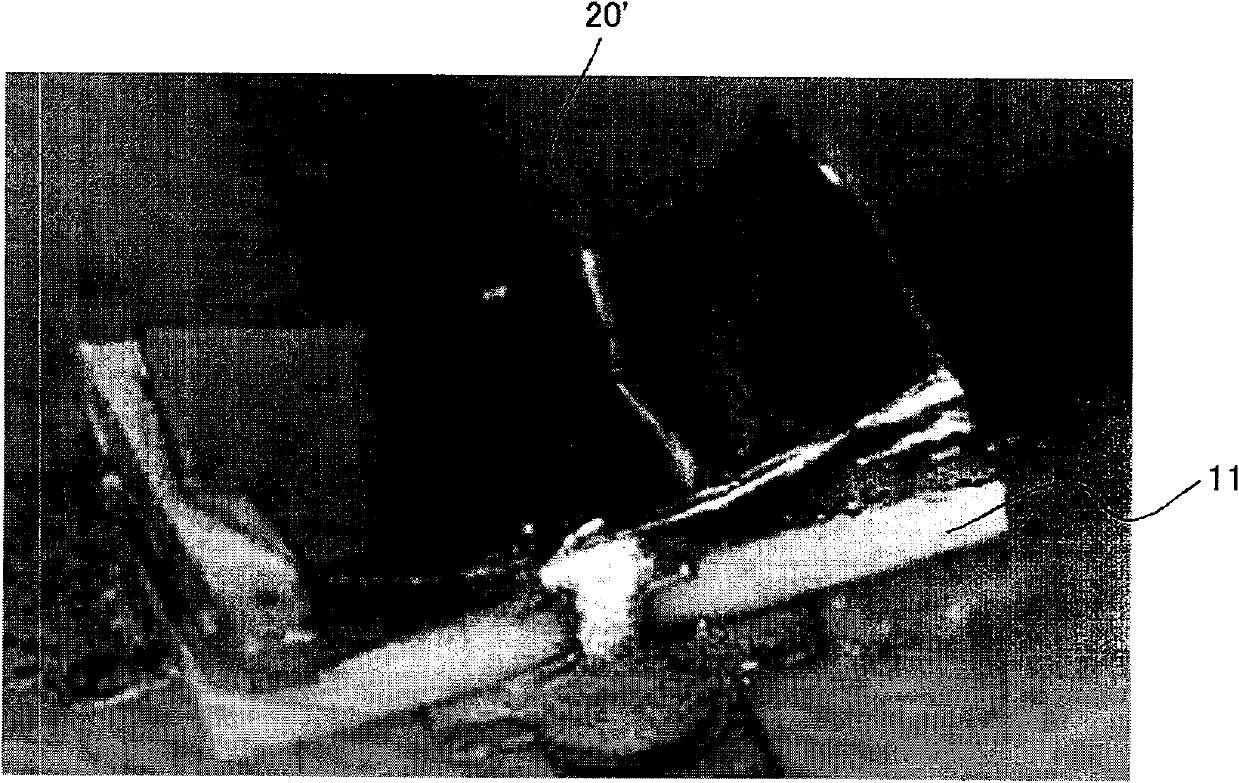

[0107] The inventors of the present invention actually produced a protection element, and conducted a current conduction test to evaluate both the current interruption operation of heating of the heating resistor and generation of overcurrent. made with Figure 10 The composition shown shall prevail for the protection element. Specifically, if Figure 11 to Figure 13 As shown, as the reference distance member 40, two wedge members 51, 52 corresponding to the above wedge members 41, 42 are prepared, these wedge members 51, 52 are inserted under the elastic member 20', and the elastic member 20' The central portion is bent into a substantially U-shape and is in an elastic state. In addition, the elastic member 20' is formed of a flat material made of super phosphor copper C5191-H, with a thickness of 0.05 mm, a width of about 2.5 mm, and a length of about 5 mm.

[0108] First, such a protective element is actually heated using a predetermined heating operation test device to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com