Mechanical stepped speed changer for harvester

A harvester and transmission technology, applied to harvesters, mechanical drive clutches, mechanical equipment, etc., can solve the problems of time-consuming and complicated operation, heavy gearbox weight, and high cost of use, and achieve simple operation, reduced fuel consumption, and reduced costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

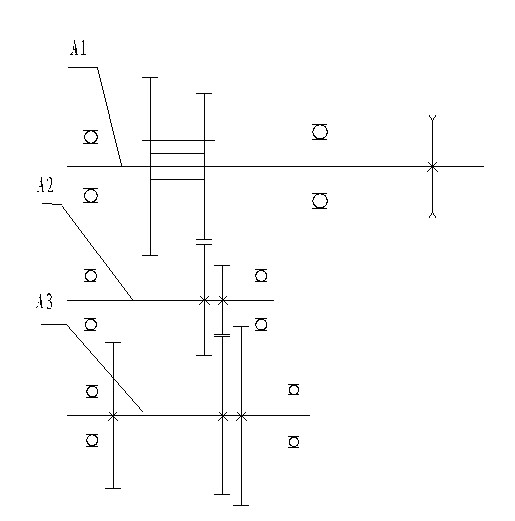

[0030] Such as figure 1 As shown, the transmission system of the present invention includes a power input shaft system A1 , an intermediate shaft system A2 and a power output shaft system A3 arranged in parallel in sequence.

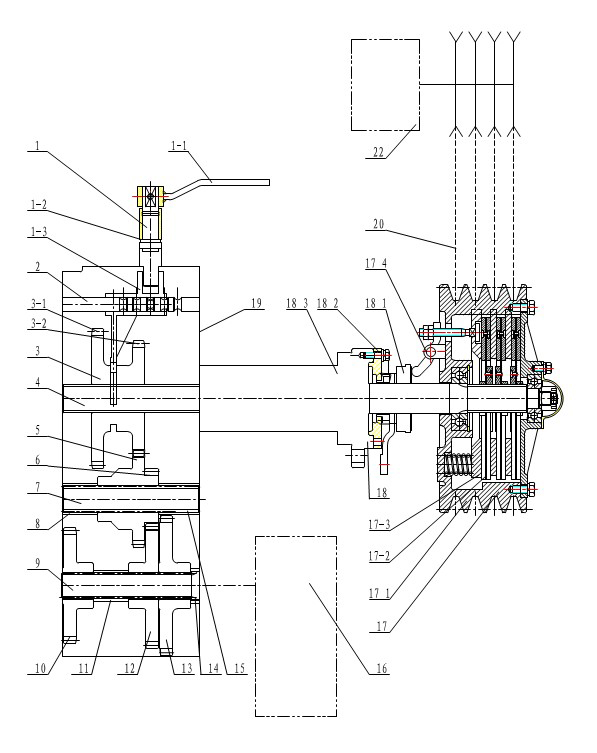

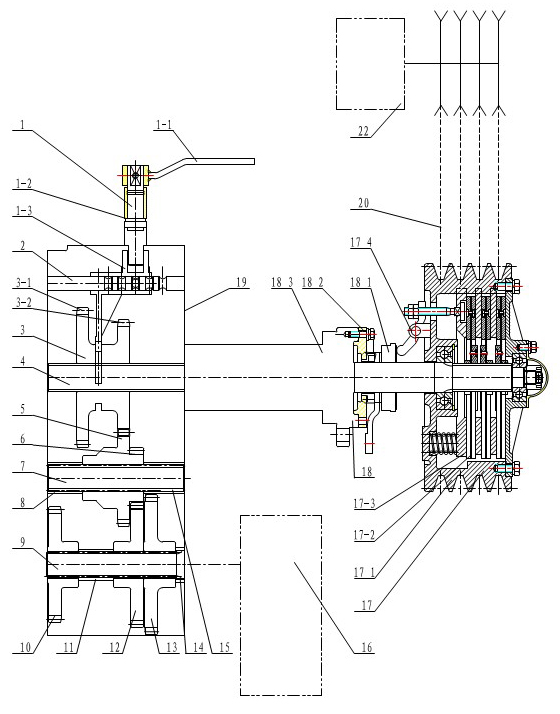

[0031] Such as figure 1 and figure 2 As shown, the power input shaft system includes a double sliding gear 3 installed on the power input shaft 4, and a clutch assembly 17 and a separation pawl system assembly 18 installed at the input end of the power input shaft 4; wherein : the double sliding gear 3 includes a parallel integrated double sliding gear I 3-1 and a double sliding gear II 3-2; the clutch assembly 17 includes a clutch 17-1, a friction plate 17-2, a light plate 17-3 and a clutch The lever 17-4; the separation claw system assembly 18 includes a separation claw 18-1, a separation claw seat 18-2, and a separation coupling sleeve 18-3.

[0032] Such as figure 1 and figure 2 As shown, the intermediate shaft system includes shaft sleeve I8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com