Vortex prevention device for relieving fluid vortex

A fluid vortex and anti-vortex technology, applied in the field of vortex, can solve problems such as difficult to eliminate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

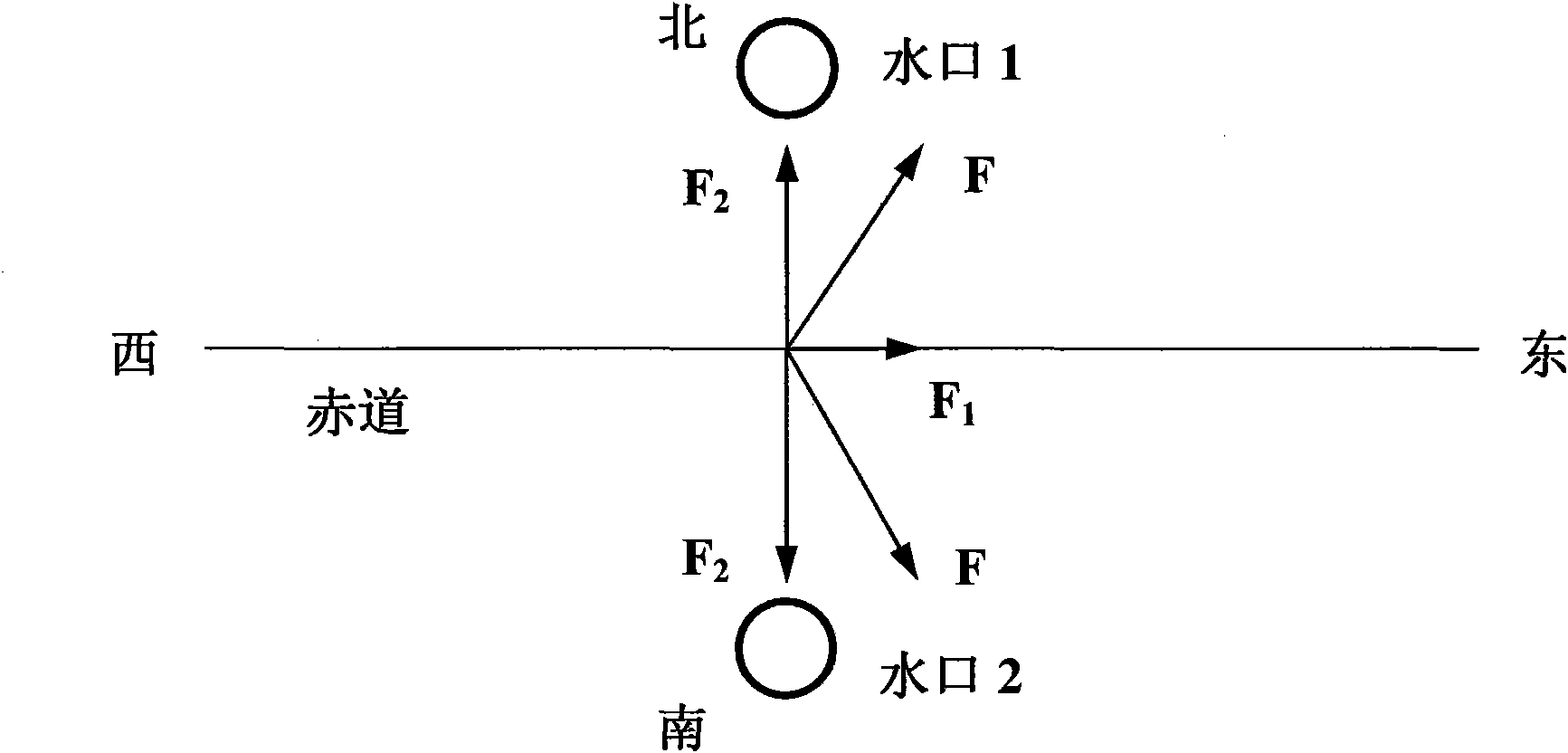

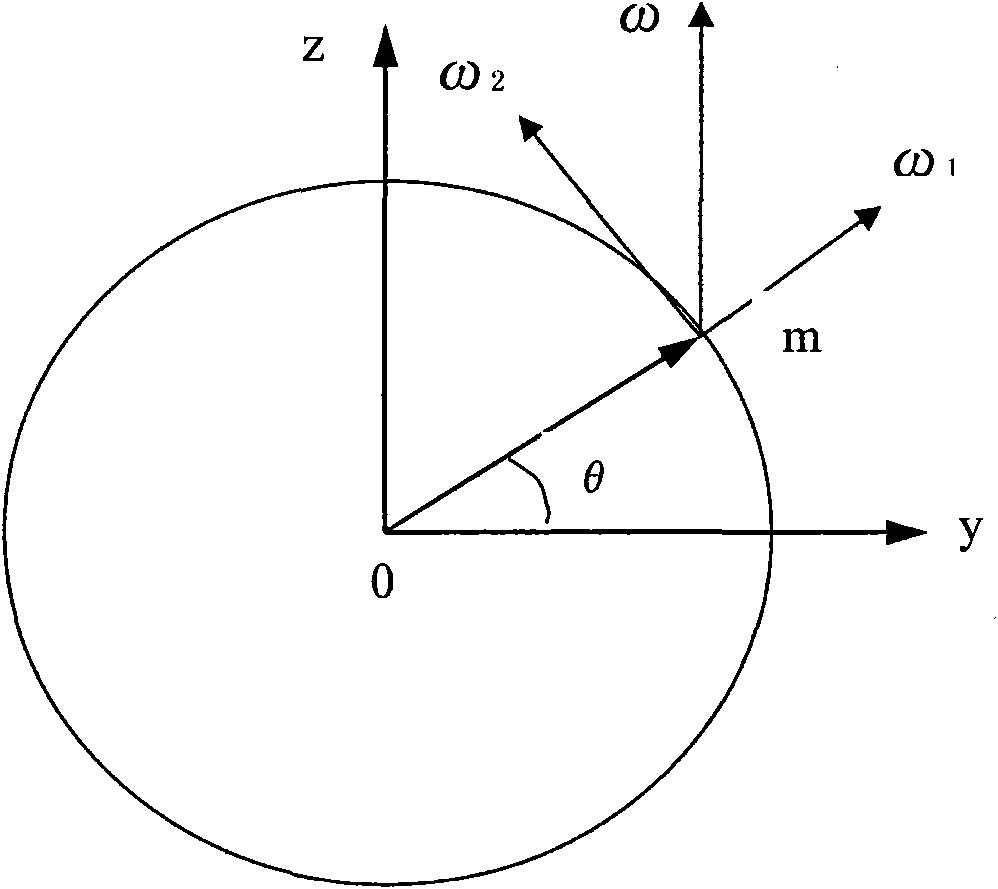

[0024] Due to the centrifugal force generated by the rotation of the earth, the magnitude and direction of the force are different according to the different geographical locations in the northern and southern hemispheres. The strength and direction of the vortex produced by the fluid are also different. The vortex in the southern hemisphere is clockwise, and the vortex in the northern hemisphere is counterclockwise. The present invention has different placement schemes according to the different directions of the vortex.

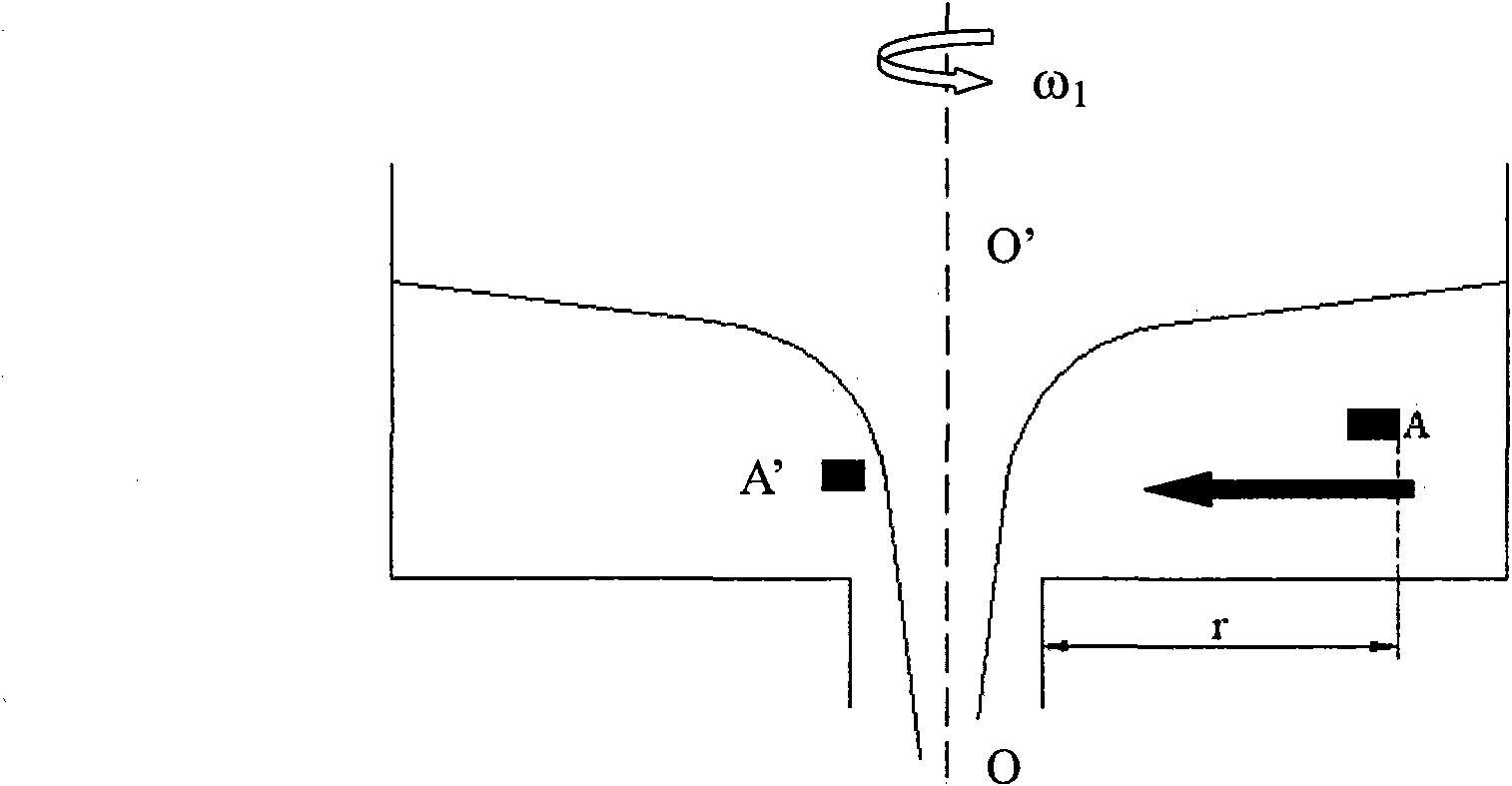

[0025] based on the following Figure 4 A, B, C and Figure 5 A, B, and C specifically illustrate the implementation of the anti-rotation device.

[0026] Figure 4 A is the anti-swirl device for reducing fluid vortex when it is located in the northern hemisphere. Its structure is: 3 refractory bricks made of anti-erosion refractory materials are built around the nozzle as shown in the figure. Refractory bricks 1, 2 and 3 have the same cross section, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com