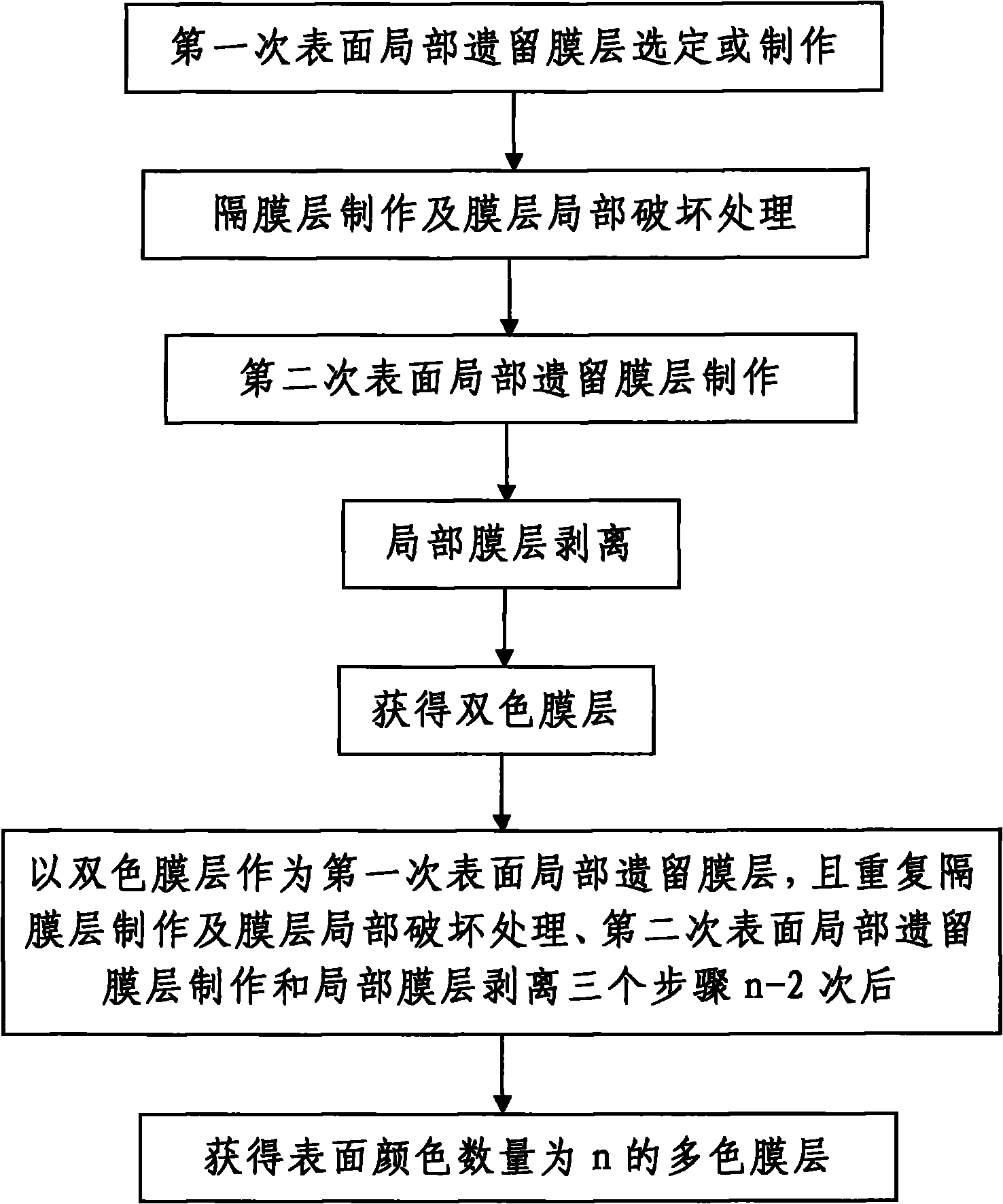

Method for manufacturing multicolor wear-resistant metal decorative film layer

A wear-resistant metal and metal film layer technology, applied in lamination auxiliary operations, chemical instruments and methods, lamination, etc., can solve the problem of poor environmental protection and wear resistance of the surface film layer, low efficiency of manual ink coating, and limitations Application of products and film quality issues, to overcome poor wear resistance and non-environmental protection, improve product application range, and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, the product to be produced is a black-gold two-color sand line. Correspondingly, when making the first partial surface film layer in step 1, a vacuum ion coating machine is used and the conventional PVD vacuum coating method is used in the described process. Coating a film layer on the surface as the first local residual film layer on the surface, the film layer one is a TiC film layer, and when vacuum coating is performed, the vacuum degree is 0.85Pa, and the C 2 h 2 The flow rate of Ar is 600 sccm, the flow rate of Ar used is 20 sccm, and the coating time is 6 minutes. In step 201, firstly, the material of the first partial film left on the surface is judged: in this embodiment, since the first partial film left on the surface is a semiconductor film or a carbon compound film, machining tools, chemical The etching method or the electrochemical etching method is used to locally destroy the first local residual film layer on the surface, and corresp...

Embodiment 2

[0049] In this embodiment, a blue-gold two-color sand line needs to be produced, and the production of the two-color film layer needs to be completed accordingly, and the production process is as follows:

[0050] Step 1. Select or make the first local residual film layer on the surface: first, select a straight and smooth outer surface on the processed substrate as the treatment surface; after that, use the conventional PVD vacuum coating method on the treatment surface Coating a film layer—as the first partial residual film layer on the surface. In this embodiment, the substrate to be processed is a 304 stainless steel plate, and the treated surface is a mirror surface.

[0051] After the treatment surface is selected, the treatment surface should be cleaned (ie pre-treatment cleaning) and dried immediately to keep the treatment surface clean. In this embodiment, when cleaning, the ultrasonic cleaning production line is used to clean in three steps: first, the surface of th...

Embodiment 3

[0067] In the present embodiment, different from Embodiment 2: the product to be made in the present embodiment is a blue-gold-silver three-color decorative film layer (wherein, the color quantity n=3 of the multi-color film layer needs to be made), and The blue-gold two-color film layer made in Example 2 is used as the first local residual film layer on the surface. After repeating steps 2 to 4 once, a three-color film layer with a color quantity of 3 is obtained correspondingly, and step 2 is repeated. The specific production process to step 4 is as follows:

[0068] First, make a diaphragm layer. The diaphragm layer produced in this example is a Zr film layer. A vacuum multi-arc ion coating machine is used for coating and the vacuum degree during coating is above 0.02Pa. Before coating, a vacuum furnace body is used at 80°C Heating and heating time is 5 minutes, and cleaning with argon ions: the flow rate of input argon gas is 150soom, the bias voltage of the workpiece is -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com