Ionic membrane electrolytic bath device for preparing alkali through oxygen cathode

A technology of ionic membrane electrolyzer and oxygen cathode, which is applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of high power consumption, difficult sealing, non-compliance, etc., and achieve the effect of overcoming the inability to weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

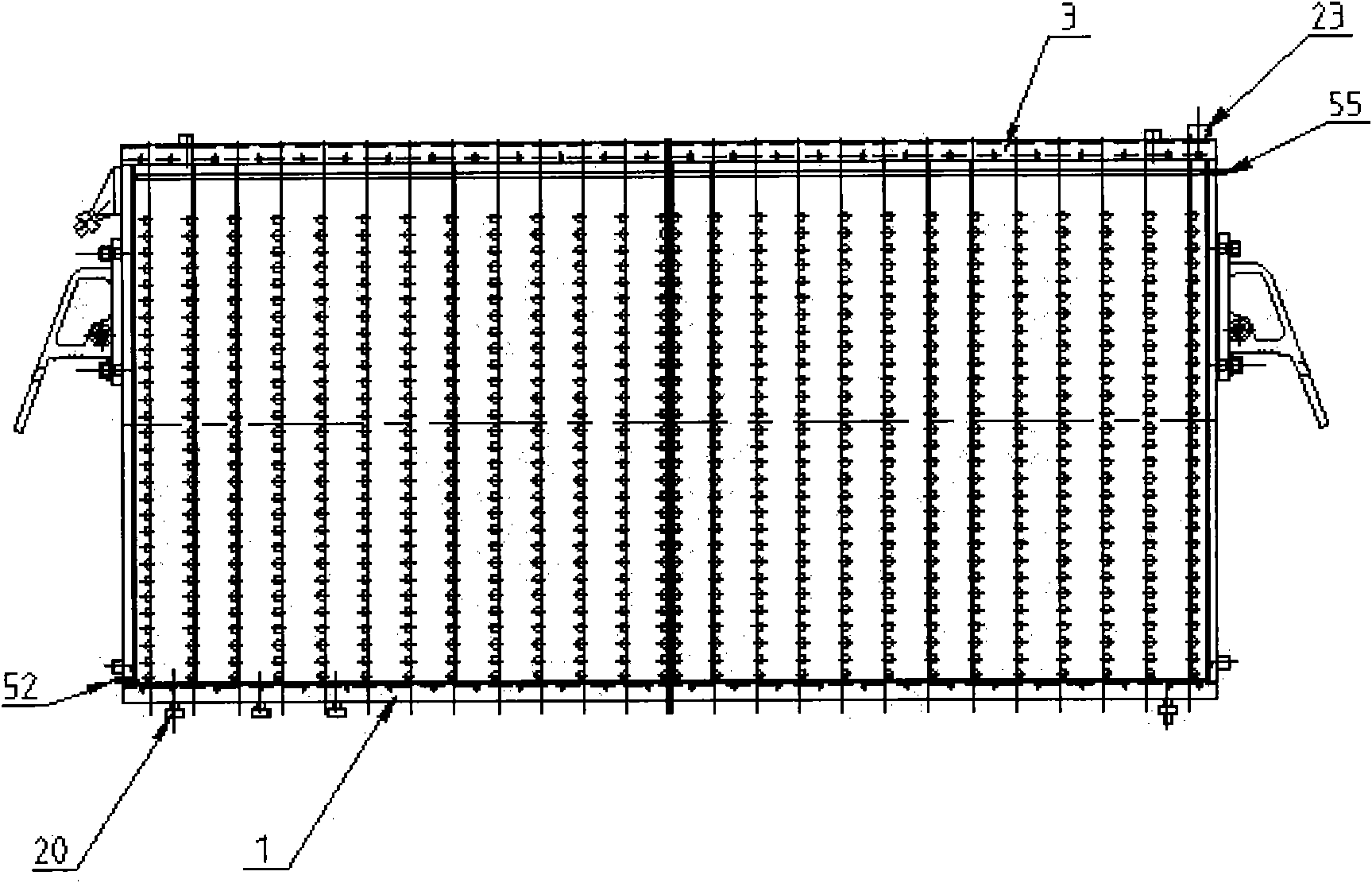

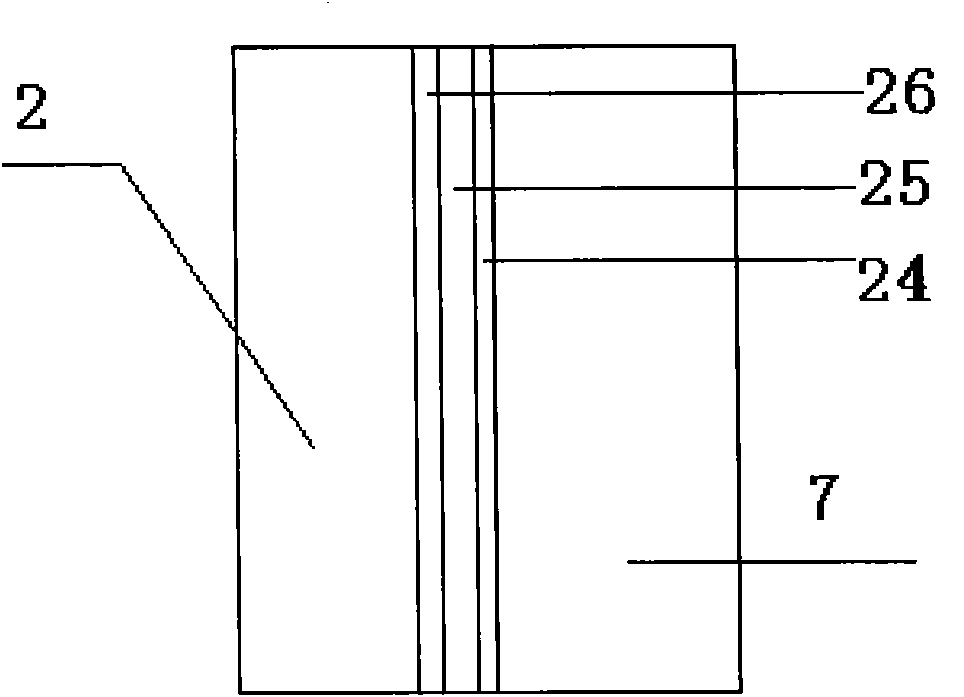

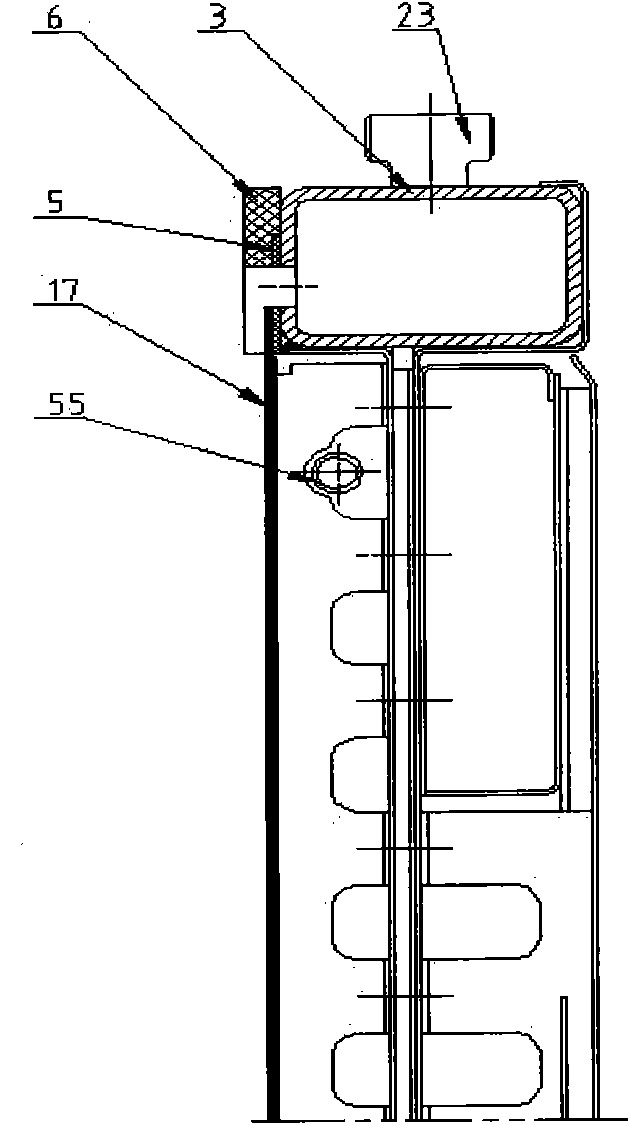

[0036] Combine below Figure 1 to Figure 5 , the present invention is further described:

[0037] An oxygen cathode ion membrane electrolyzer device for making alkali mainly includes an anode of an ion membrane electrolyzer and a cathode of an ion membrane electrolyzer, and a cathode gas chamber 7 and a catholyte chamber 2 are arranged on the cathode side of the ion membrane electrolyzer, and the cathode An oxygen cathode diffusion electrode 17 is arranged between the gas chamber and the catholyte chamber; oxygen is delivered to the cathode gas chamber 7, and the oxygen passes through the oxygen cathode diffusion electrode 17 to interact with H 2 O together transforms into OH - Enter the catholyte chamber 2, thereby generate NaOH in the catholyte chamber 2, while there is no H in the negative electrode of the ion-exchange membrane electrolyzer 2 Precipitate. Therefore, the decomposition voltage is reduced by 1.22 volts, estimated by the standard potential, and more than 56%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com