Fuel cell membrane electrode, preparation method thereof and fuel cell

A fuel cell membrane and electrode technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of membrane electrode performance attenuation, achieve the effects of reducing decomposition voltage, prolonging service life, and inhibiting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Another embodiment of the present invention provides a method for preparing a fuel cell membrane electrode as described above, comprising the following steps:

[0056] The anode catalyst slurry and the cathode catalyst slurry are prepared by dispersing the catalytically active component and the anti-reverse material in a solvent, and the anti-reverse material includes IrO 2 , RuO 2 One or more of , NiO and CoO;

[0057] The anode catalyst slurry and the cathode catalyst slurry are respectively applied to two sides of the proton exchange membrane, and after drying, an anode catalyst layer and a cathode catalyst layer are obtained.

[0058] In some embodiments, before applying the anode catalyst slurry and the cathode catalyst slurry, the proton exchange membrane is soaked in 5% to 10% hydrogen peroxide for 0.5 to 2 hours at a treatment temperature of 60 to 100° C. ~12mol / L sulfuric acid treatment for 0.5~1h, the treatment temperature is 60~80°C, after cleaning, dry at ...

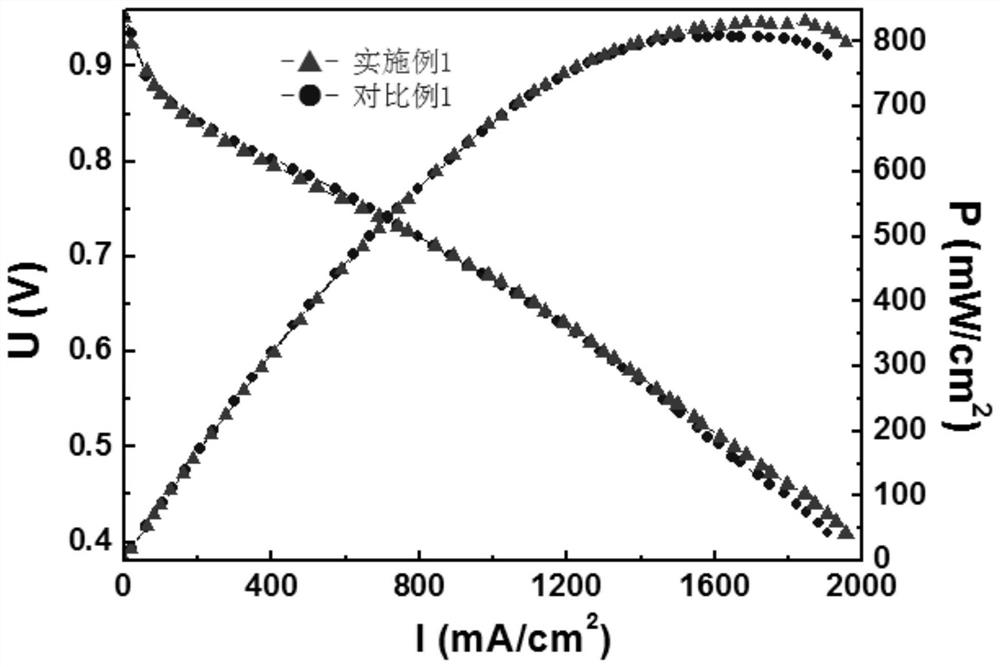

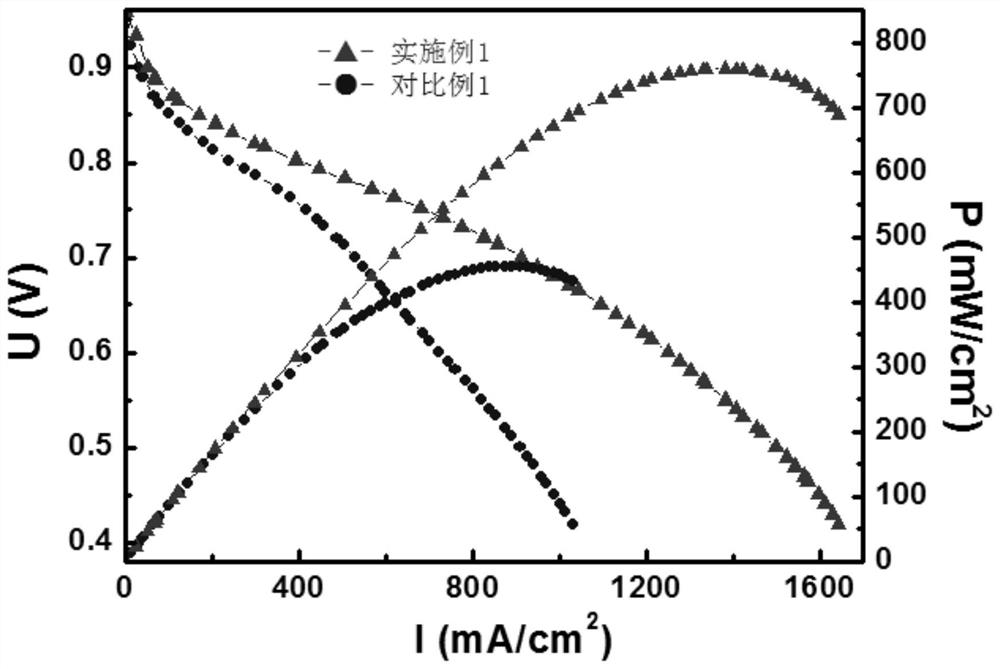

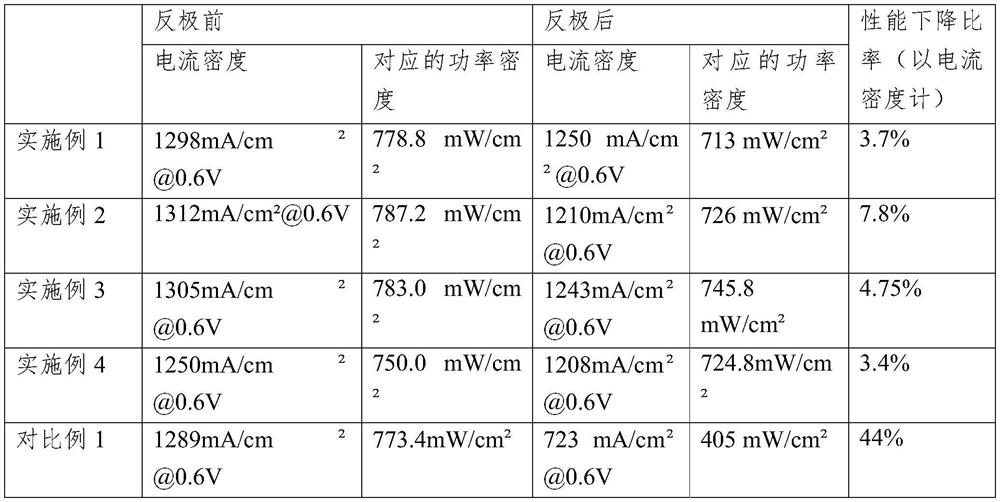

Embodiment 1

[0068] This embodiment is used to illustrate the fuel cell membrane electrode disclosed in the present invention and its preparation method, including the following steps:

[0069] Get the Pt / C catalyst that mass fraction is 40% respectively, add in two beakers respectively, first add a small amount of isopropanol solution in each beaker, stir and dissolve the catalyst, get two other beakers and add isopropanol respectively, Add the perfluorosulfonic acid polymer solution with a mass content of 20% into two beakers, stir ultrasonically, then pour the solution containing the perfluorosulfonic acid polymer into two beakers containing the Pt / C catalyst, and ultrasonically Carry out 60min alternately with stirring and mixing, prepare the homogeneous catalyst slurry of dispersion mixing, weigh IrO 2 Added to the catalyst slurry, ultrasonic and stirring mixed alternately for 60min. In catalyst slurry, Pt / C catalyst: perfluorosulfonic acid polymer: IrO 2 The mass ratio is 2.5:1:1. ...

Embodiment 2

[0072] This example is used to illustrate the fuel cell membrane electrode disclosed in the present invention and its preparation method. Most of the operating steps in Example 1 are different in that:

[0073] In catalyst slurry, Pt / C catalyst: perfluorosulfonic acid polymer: IrO 2 The mass ratio is 2.5:1:0.25.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com